Howdy all!

I've read of instances where guys will use 240volt rated heating elements with a 120volt supply to heat their stills. Is there some advantage to doing this instead of using 120v rated elements with 120v supplies?

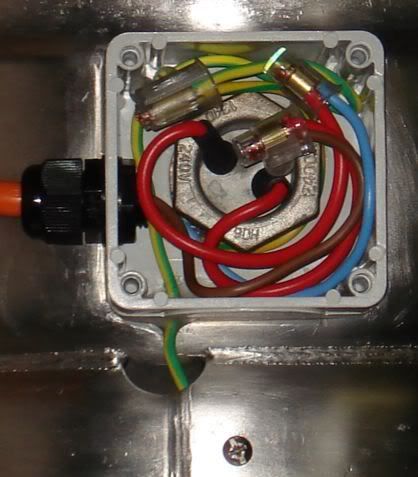

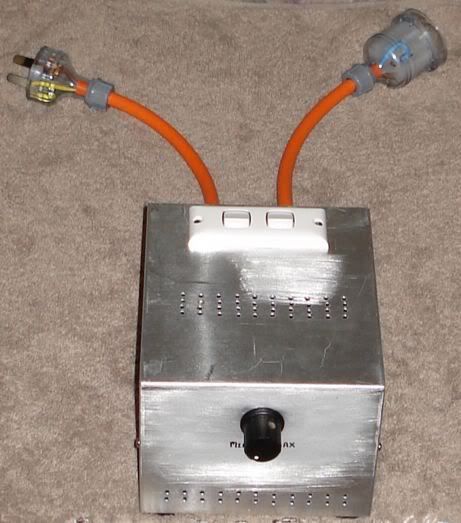

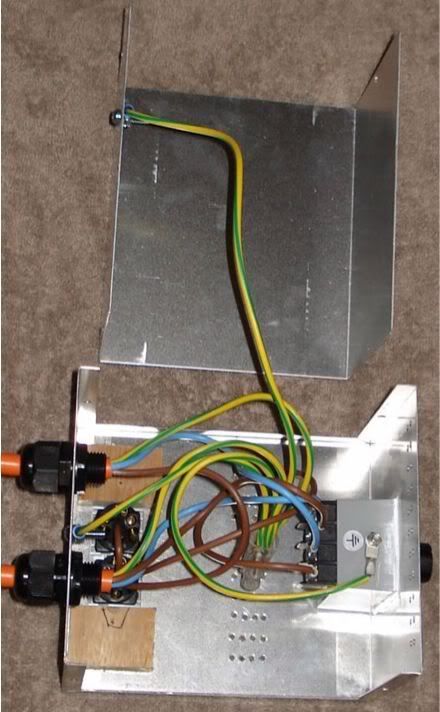

Also, does anyone have a good technique or nice pix of properly installing an electric heating system to a keg? I've seen some examples, but most look like fire traps. I've got the drilling and welding on a half connector business down pat. I'm looking for a slick example that encloses the switches, element connectors, rheostats, wiring, etc, inside a square aluminum electrical box attached somehow to the keg - to minimize any exposed electrical connections.

Thanks!

Electric heater questions

Moderator: Site Moderator

-

BW Redneck

- Trainee

- Posts: 775

- Joined: Sun Dec 10, 2006 11:57 am

- Location: 1000 acre farm, Ohio

The 240V-120V thing that you mentioned is done so that the element runs at a lower wattage than if you had used 240V, since some want a high wattage going in at the heat-up and want to cut it down to normal for the rest of the run and not want to have to install several elements.

At least, that's what I've read.

At least, that's what I've read.

"If you can't dazzle them with brilliance... baffle them with bullshit."

"Don't steal. The government hates competition."

"Believe none of what you hear, and only half of what you see"

20lt small pot still, working on keg

"Don't steal. The government hates competition."

"Believe none of what you hear, and only half of what you see"

20lt small pot still, working on keg

Thanks BW. That makes sense.

I'm thinking about using two 120v 1400W elements.

I found a 1400W dimmer on eBay for cheap last week, so I'll hook it up to one of the elements, then thru an on-off switch. The other element will be on a separate on-off switch and will be used as a booster heater till the still comes up to temp. Then I'll switch it off and let the dimmer circuit set the cruising temp. Which looks similar to what HookLine has done.

HookLine,

That is about what I was thinking about.

How is the square junction box attached to the still?

Thanks guys.

I'm thinking about using two 120v 1400W elements.

I found a 1400W dimmer on eBay for cheap last week, so I'll hook it up to one of the elements, then thru an on-off switch. The other element will be on a separate on-off switch and will be used as a booster heater till the still comes up to temp. Then I'll switch it off and let the dimmer circuit set the cruising temp. Which looks similar to what HookLine has done.

HookLine,

That is about what I was thinking about.

How is the square junction box attached to the still?

Thanks guys.

Guy

Standard Roof and Gutter silicone from the local hardware store.GuySmilie wrote:HookLine,

That is about what I was thinking about.

How is the square junction box attached to the still?

http://www.selleys.com.au/Selleys-Roof- ... fault.aspx" onclick="window.open(this.href);return false;" rel="nofollow

Clean and dry the surfaces real well first. I used mineral turpentine (I think you guys call it kerosene or paraffin.)

Check the temp range of the silicone (usually available on the companies web site), because some silicones (the hydrophobic ones) have a low operating temp range. Meaning they will melt at stilling temps. But the standard stuff is usually okay.

Let it cure fully (usually 72 hours).

Do a test patch on the surfaces to make sure it sticks.

Be safe.

Be discreet.

And have fun.

Be discreet.

And have fun.