Cajun Flute

Moderator: Site Moderator

Cajun Flute

Okay guys, I've been messing up the flute talk section with random images of my ongoing flute build, so I finally decided to start a new topic here to cover the entire process for anyone who's interested. I'm an open book, so don't be bashful about critiquing the build, asking questions about my thinking, or even asking for running dollar amounts invested (for all you aspiring flute builders!) I have to start off by saying thank you to all of the members of this site for all of the help along the way and especially OldDog and all the other flute builders who I've shamelessly stolen ideas from. I also need to thank my best buddy and neighbor for helping me with every aspect of this build. The end result is for us to be sitting on the back porch sippin on our own whiskey while we admire our finished product!

Last edited by RayDean on Wed Mar 30, 2011 5:16 pm, edited 1 time in total.

Re: Cajun Flute

My plan is to make a 30" tall 4" column that sits directly onto a stainless keg with a 4" triclamp fitting. I also plan to incorporate OD's drop in dephlegmator into the design. I come from an oil refining background, so you might see design and material influences from that folded into the build.

After tons of reading, drawing, research, pricing, and ordering, it all started like this.

After tons of reading, drawing, research, pricing, and ordering, it all started like this.

Re: Cajun Flute

My machinist buddy was supposed to shorten the ferrules I'm using for the sightglasses when he shaped them to fit on the outside of the column, but forgot. It was a freebie, so I'm going to stick with the extra length and call it "character".

Re: Cajun Flute

I'm using the thicker type-M 4" pipe for the column and quickly discovered that I wouldn't be able to hammer the triclamp ferrules into both ends, so I again called in a machinist favor and had 1" of the ID turned to accept the ferrules. I also had him reduce the ID of the ferrule that goes on the top of the column so that it was flush with the ID of the pipe. This will allow me to slide in the drop-in plate tree and maintain a very tight tolerance between the plates and the wall.

Re: Cajun Flute

I purchased a 1' square piece of 1/8" flat plate for the plates and the tube sheets for the dephlegmator and shotgun condenser. Did a rough cut of all the circles and then turned them over to a buddy to spin on his lathe. In hindsight, the 1/8" is way too thick, but what the hell... On the left is the 4 plates, 2 tubesheets, and 6" long piece of 4" that will eventually get a slice taken out and shrunken down so that it will slide inside the column as the dephlegmator. On the right is a scrap of 3" and the two tubesheets for the shotgun condenser.

Re: Cajun Flute

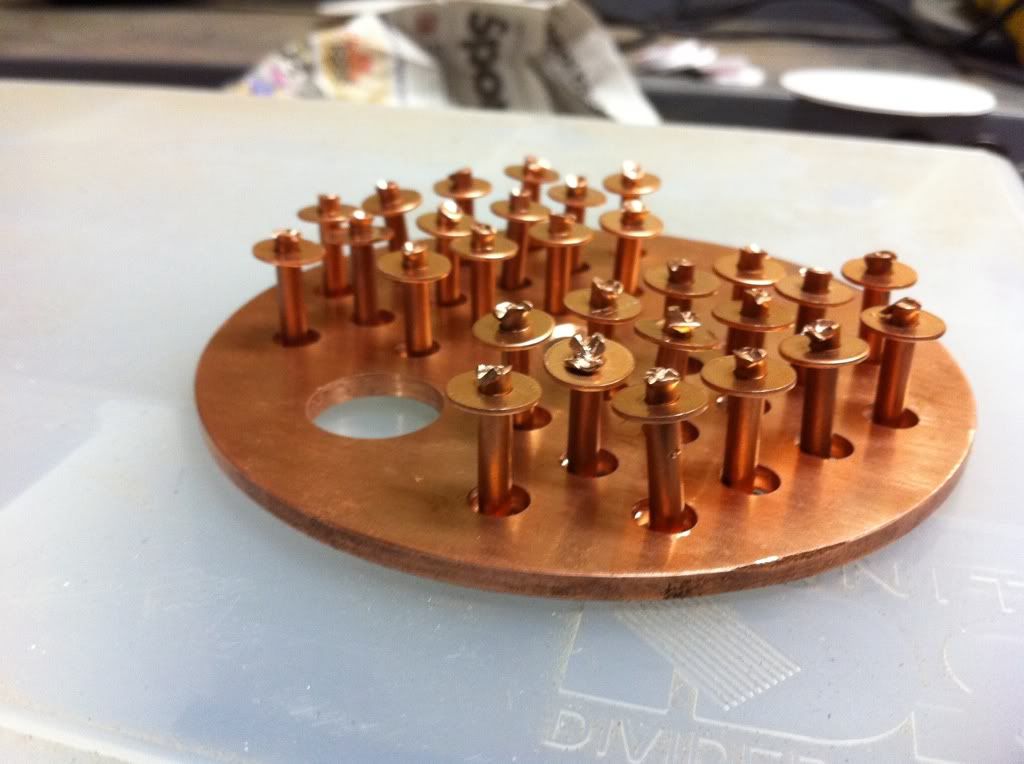

Drilled my holes for the 3/4" tubes for the dephlegmator and assembled. Really excited about the tight fit I was able to pull off!

Re: Cajun Flute

Felt so good about the depleg, I continued on and assembled the 18" long tube bundle for the shotgun condenser using 1/2" tubes. Really pleased with this one as well!

Re: Cajun Flute

Dang! Looking great! Keep the updates coming.

Re: Cajun Flute

Ray,

Looks great! How can you shrink the 4" shotgun so it can slide tightly into the 4" column? Do you have to use sheet copper to make the outer wall of the shotgun or can you do it with tubing?

RB

Looks great! How can you shrink the 4" shotgun so it can slide tightly into the 4" column? Do you have to use sheet copper to make the outer wall of the shotgun or can you do it with tubing?

RB

Re: Cajun Flute

Nice job so far! What's the problem with the 1/8 plates?

Re: Cajun Flute

To make the shotgun dephlegmator, I used two of the extra 1/8" disks I had spun for the plates. I drilled holes for the 3/4" tubes in them, then using a 6" long piece of 4" pipe cut off the column, I cut a slice out it and brazed it back together using pipe clamps to squeeze the gap together. This was then brazed between the two end cap tubesheets allowing the dephleg to slide into the column. The stainless tubing is just to show one of the two holes I drilled for the cooling water supply and return.

Re: Cajun Flute

No real problems with the 1/8" plates, just really bulky and it takes lots of heat and solder/brazing rods to work with. It's all very industrial and heavy duty... prolly just a little overkill!ginjo wrote:Nice job so far! What's the problem with the 1/8 plates?

Re: Cajun Flute

Here are the two shotgun coolers under construction

Re: Cajun Flute

Looks great Ray, keep it coming man...

♦♦ Samohon ♦♦

Beginners should visit The New Distillers Reading Lounge and the Safety and Related Issues among others...

Beginners should visit The New Distillers Reading Lounge and the Safety and Related Issues among others...

Re: Cajun Flute

Here is the dephleg with the cooling water supply and return tubing. This assembly will hang 2.5" below the stainless 4" x 2" offset triclamp adapter plate with the cooling tubing penetrating the flatcap.

Re: Cajun Flute

Endedup with a nice fit on the drop-in dephleg.

Re: Cajun Flute

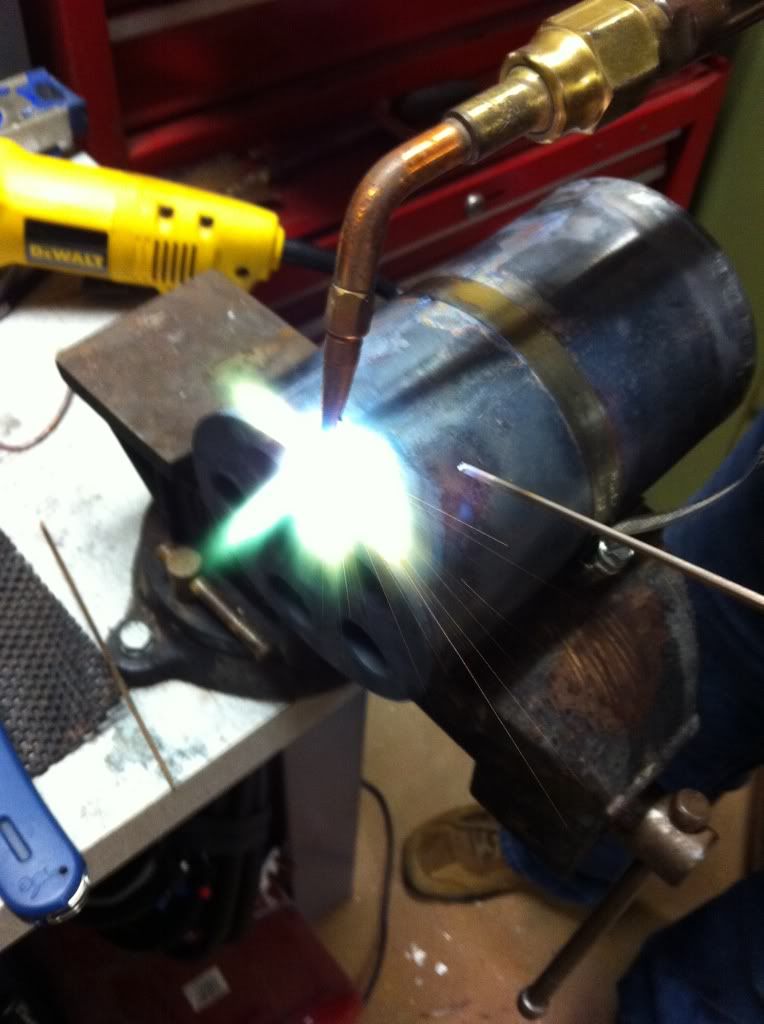

Here's the keg and column back from the welder. I'm sure it'll look better once I get it cleaned up. also had a 1" drain and a thermowell welded to the boiler.

Re: Cajun Flute

Nice job Ray, that's exactly the way I produced the drop in dephlegmater for Flute II, I annealed the piece of tubing first, which makes it easier to compress to fit inside the 4"column, I then marked the overlap while it was inside the 4". cut off the surplus, and hard soldered the joint, to complete.

OD

OD

OLD DOG LEARNING NEW TRICKS ......

Re: Cajun Flute

Starting assembly of the 3" shotgun condenser and finally putting everything together.

Re: Cajun Flute

Maybe I missed it, but why the drop in dephegm? What about just having a section of 4'' with tc on each end?

Soldering looks good -- what did you use? Any probs with the tubes expanding (lengthening) when heating?

Soldering looks good -- what did you use? Any probs with the tubes expanding (lengthening) when heating?

Re: Cajun Flute

Air purge for the product condenser?

Re: Cajun Flute

I don't remember why I went with the drop-in dephleg. Might have thought it would save money on ferrules and clamps, but it sure would have been easier in hindsight. We used hard solder on all of the heat exchangers and joined all of the tubes to the tubesheet first then slid the assembly into the shell and hard soldered that. No problems with tube lengthening. I'll make a vent of some kind for the outlet of the condenser when I make the parrot.

Re: Cajun Flute

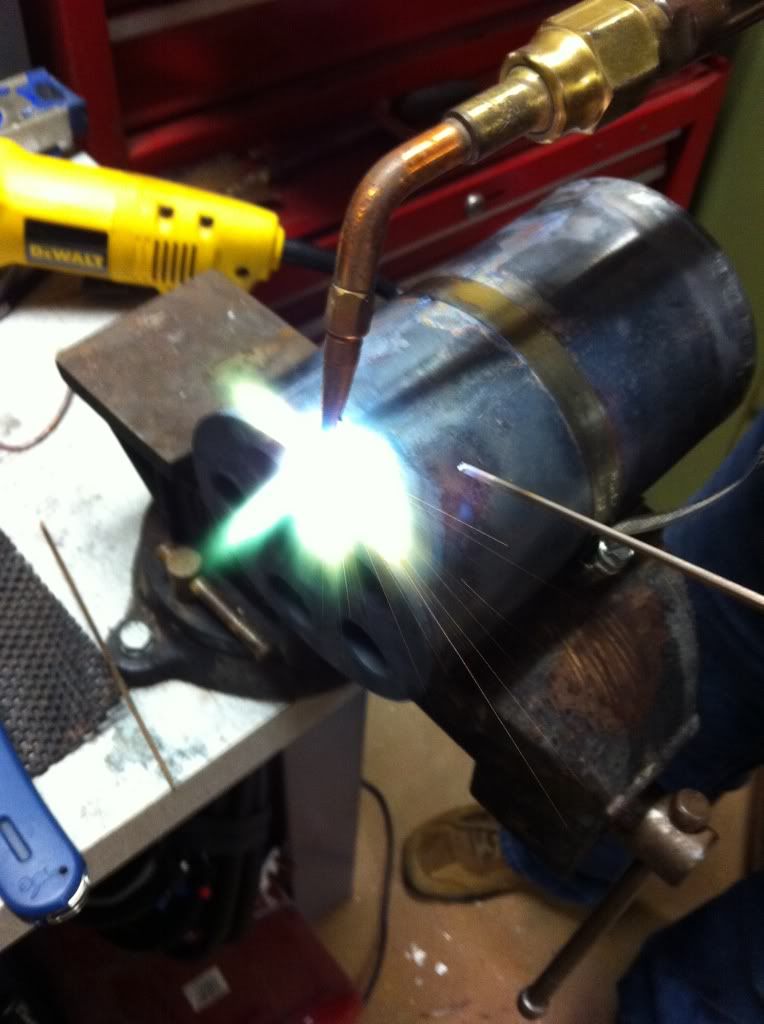

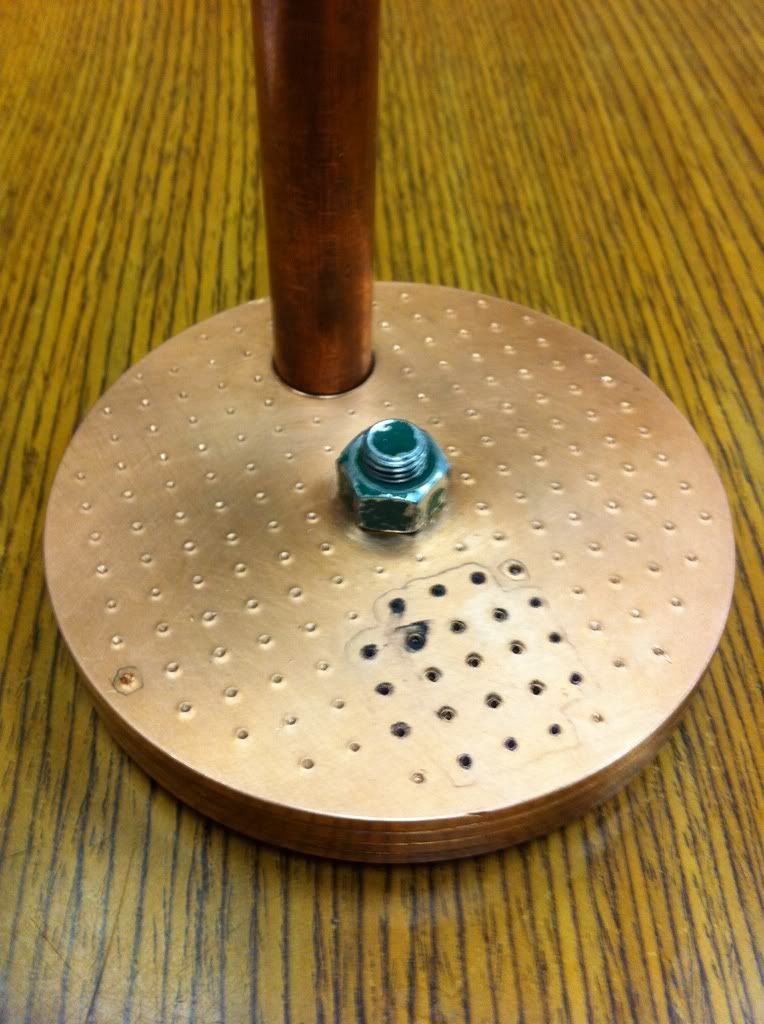

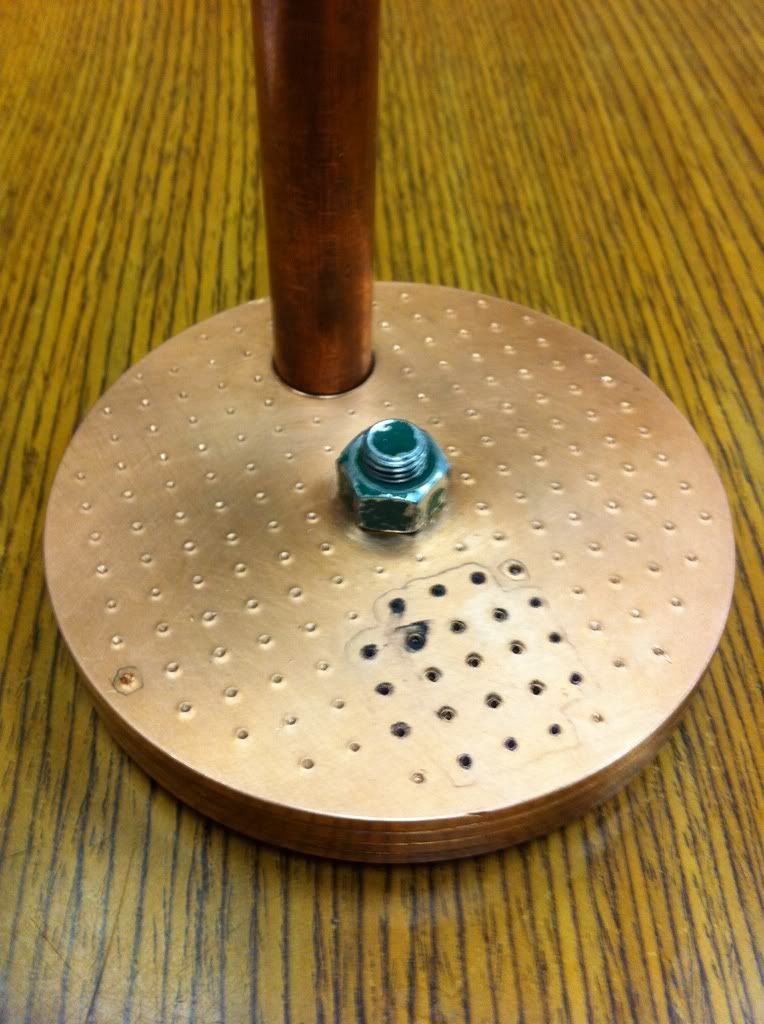

On to the plates. I originally wanted to make valve trays using copper rivets but I thought that was too complicated. Started to make my sieve plates and center punched all my holes.

Exceeded my talent level by breaking about half a dozen 1/16" bits before I even got through a single plate. Back to plan A.

Exceeded my talent level by breaking about half a dozen 1/16" bits before I even got through a single plate. Back to plan A.

-

condensificator

- Rumrunner

- Posts: 653

- Joined: Wed Jul 28, 2010 7:34 pm

Re: Cajun Flute

looking good dude! definitely heavy-duty/industrial. i'm excited to see it finished.

Re: Cajun Flute

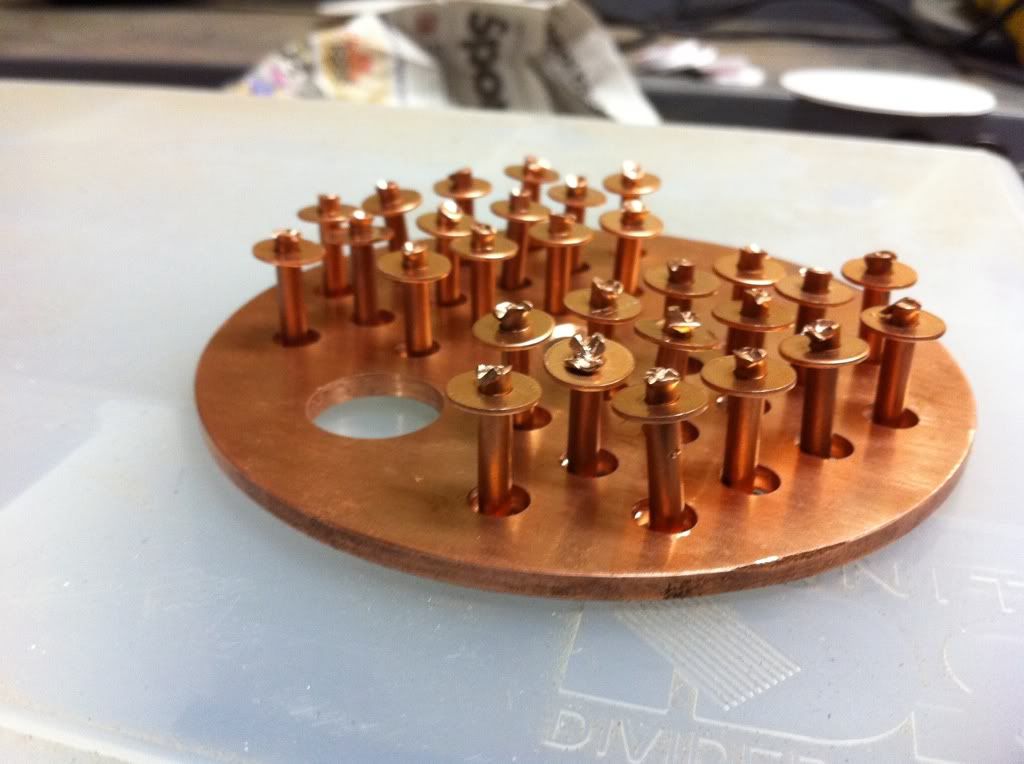

Mostly finished with my plate tree. Plan is to hang this to the bottom of the dephleg somehow so that all of the guts come out of the top of the column as one assembly.

Re: Cajun Flute

Thanks a lot! I thought about leaving it with a cup brush or shot peen finish, Im prolly gonna shine her up so it'll look somewhat respectable next to the bublifier!condensificator wrote:looking good dude! definitely heavy-duty/industrial. i'm excited to see it finished.

Re: Cajun Flute

The collection cup height (at the bottom of the downcommer) vs the rider height.... how did you decide on that ratio? Just make the cup a 'bit' taller? I heard there is some issue with sieve plates not running steady through the whole run... with bubble caps being preferred... what do you think? The sieve thing you have done looks real sharp and must have taken a lot of skill. Seems that the sieves should be easier to make than bubble caps, but you are doing a bang up job and that must take a lot of time too.... thoughts? Planning a plate deal myself - leaning bubblers - but would love to hear everyones thoughts. Great build again.....!

-

condensificator

- Rumrunner

- Posts: 653

- Joined: Wed Jul 28, 2010 7:34 pm

Re: Cajun Flute

yes! you have one of the allthread plate trees. very nice, versatile solution for an adjustable bubbler set up.

as far as the "shine" of the finished rig, i am all about a good, deep, natural patina...i just take the pictures after stages of fabrication.... it only looks polished after doing the finish work...after that, it's all about telling the story of where it's been.

as far as the "shine" of the finished rig, i am all about a good, deep, natural patina...i just take the pictures after stages of fabrication.... it only looks polished after doing the finish work...after that, it's all about telling the story of where it's been.

Re: Cajun Flute

Ginjo, You've got three basic choices on plate or tray designs. Sieve (perforated), bubble cap, or valve. I chose valve because of ease of manufacturing and they kinda offer the best of both worlds as far as the eventual self draining of a sieve and the potential to hold liquid longer like a bubble cap. The real kicker for me is that you don't have to be exact on your calculations and the valves will always open as much ad needed to allow more vapor up the column. As far ad the downcomer cups, I just used a 3/4" cap and left it that height. It's only real purpose is to act as a p-trap to keep gases from rising up through the downcomer. The liquid level on eack plate will be set by the 1/2" of downcomer tube sticking up above the plate.

Re: Cajun Flute

Cool. How did you decide on the amount of play between the rivet posts and the hole diameter? Seems like once the posts rise, the limiting factor is this play and not the amount the rivets rise. Couldn't you have gone with rivet posts that were not so long?