need advice

Moderator: Site Moderator

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

need advice

Thinking about a flute build, this is 3'' type K copper

so far I have looked at old dogs magic flute and the kentucky flute

and have come up with this

rudimentary drawing, I have made the shotgun,

and i have the flanges on the deph..pinged out

any suggestions? the section i have named column, would this be a good spot to pack it full of scrubbies? to slow down the reflux from above?

or will i be slowing the vapor to the reflux above?

still not straight how it works

another question, on the 3'' x 2'' reduction at the keg.

in order to save a dime. would their be a problem in sil floss a flat plate onto the 3''

with a 2'' hand pinged flange sil flossed to the plate ?

so far I have looked at old dogs magic flute and the kentucky flute

and have come up with this

rudimentary drawing, I have made the shotgun,

and i have the flanges on the deph..pinged out

any suggestions? the section i have named column, would this be a good spot to pack it full of scrubbies? to slow down the reflux from above?

or will i be slowing the vapor to the reflux above?

still not straight how it works

another question, on the 3'' x 2'' reduction at the keg.

in order to save a dime. would their be a problem in sil floss a flat plate onto the 3''

with a 2'' hand pinged flange sil flossed to the plate ?

- cranky

- Master of Distillation

- Posts: 6516

- Joined: Fri Sep 27, 2013 3:18 pm

- Location: Pacific Northwest

Re: need advice

A 10" dephleg might be hard to control, bigger isn't always better there. I think you already know I used a 6" on my CM and 48" of CSST for my flute. Of the 2 I feel the CSST wound into a 7" Dimroth gives the best results for control ability and micro adjustments. But I do I think a 6" shotgun on top is more than enough for a good RC on a flute.

I have a flat plate for the 2"-3" transition and don't have any problems with it but I also have 7 inches above it before the first plate. One thing to think about is I think I saw where someone used a canning funnel for that transition.

I have a flat plate for the 2"-3" transition and don't have any problems with it but I also have 7 inches above it before the first plate. One thing to think about is I think I saw where someone used a canning funnel for that transition.

Last edited by cranky on Tue Apr 12, 2016 4:35 am, edited 1 time in total.

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

Re: need advice

thanks cranky, that aint noth'n but a bandsaw cut !!!

I was aware it needed to be smaller just was not sure how small

I was aware it needed to be smaller just was not sure how small

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

Re: need advice

on second thought, no cut. i will just shorten the tubes in the jacket, simpler

- cranky

- Master of Distillation

- Posts: 6516

- Joined: Fri Sep 27, 2013 3:18 pm

- Location: Pacific Northwest

Re: need advice

Sounds good Frodo, I'm looking forward to seeing what you make, you make some interesting stuff for sure.

- cranky

- Master of Distillation

- Posts: 6516

- Joined: Fri Sep 27, 2013 3:18 pm

- Location: Pacific Northwest

Re: need advice

Are you going to make the plates fixed or removable? I'm liking what mine is doing with 3 plates rather than 4 right now.

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

Re: need advice

at this time removeable. but that opens up confusion

i am aware that the bubbling up, keeps the refluxed liquid from falling back thru the drilled plates

but, if it is removeable. that will be a gap around the plate for removal

will the steam/ bubbling up keep the liquid from here also. ?

i am aware that the bubbling up, keeps the refluxed liquid from falling back thru the drilled plates

but, if it is removeable. that will be a gap around the plate for removal

will the steam/ bubbling up keep the liquid from here also. ?

- Swedish Pride

- Site Donor

- Posts: 2660

- Joined: Tue Aug 26, 2014 2:16 am

- Location: Emerald Isle

Re: need advice

it would, so the snugger the better.

Or if you are mathematically gifted I suppose you could calculate how much more of an bubblearea ( yep, very technical term there) you get with the gap and reduce the hole area you drill accordingly.

if you double your packed section to 24" it should serve you well for as an add on when and if you want to run vodka.

This is all in theory, I've read just about all the flute stuff but no hands on experience.

Or if you are mathematically gifted I suppose you could calculate how much more of an bubblearea ( yep, very technical term there) you get with the gap and reduce the hole area you drill accordingly.

if you double your packed section to 24" it should serve you well for as an add on when and if you want to run vodka.

This is all in theory, I've read just about all the flute stuff but no hands on experience.

Don't be a dick

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

Re: need advice

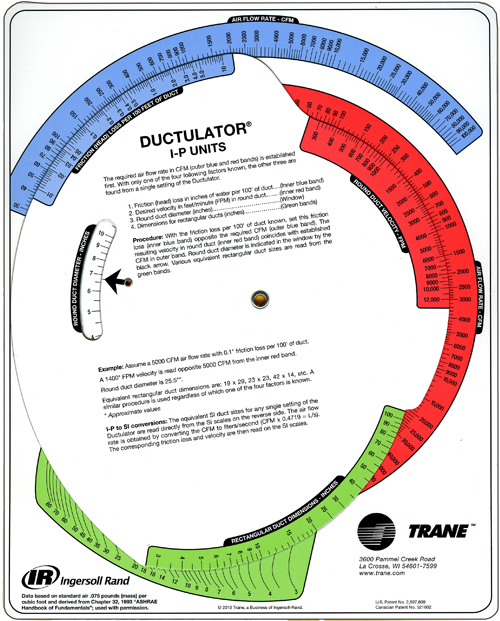

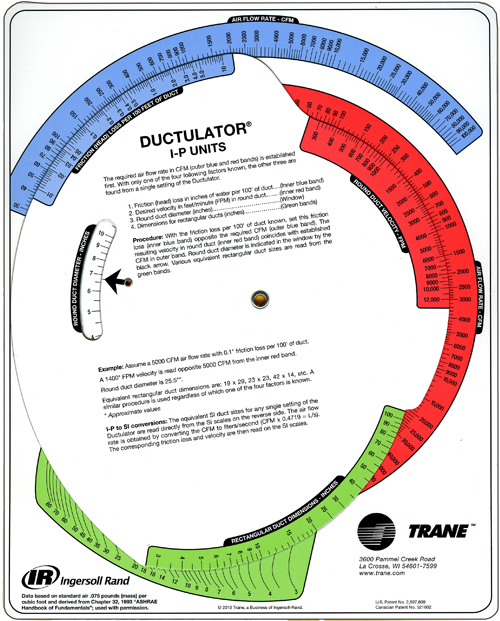

i can figure sq inch. then use a holeulater to figure hole size ..LOL

same principle as a ductulater

same principle as a ductulater

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

Re: need advice

started on this build, because of parts [money] it will be slow

i pinged some flanges and made a few plates

this is all rough, nothing has been fitted or prettyed up

i pinged some flanges and made a few plates

this is all rough, nothing has been fitted or prettyed up

- Swedish Pride

- Site Donor

- Posts: 2660

- Joined: Tue Aug 26, 2014 2:16 am

- Location: Emerald Isle

Re: need advice

Rough is the new pretty in my opinion, look at MCH's ratrod flute, that is pretties than a polished on in my eyes.

is that your plate with 4 big holes in it?

is that your plate with 4 big holes in it?

Don't be a dick

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

Re: need advice

no, those are pilot holes for my step bit on the CM for 1/2'' vapor tubesSwedish Pride wrote:Rough is the new pretty in my opinion, look at MCH's ratrod flute, that is pretties than a polished on in my eyes.

is that your plate with 4 big holes in it?

to keep the small plate from spinning and acting a fool while i drill. I marked the centers, drilled pilot holes. now i will sill floss them in place. then drill the holes bigger.

trying to hold onto a 3'' round disc is ......interesting

for the plates in the flute. i will clamp them all together, drill all the plates at one time

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

Re: need advice

I went to forum google search. typed in MCH's ratrod flute,

and get this instead

http://screencast.com/t/NJeuEnbq5b" onclick="window.open(this.href);return false;" rel="nofollow

and get this instead

http://screencast.com/t/NJeuEnbq5b" onclick="window.open(this.href);return false;" rel="nofollow

- Swedish Pride

- Site Donor

- Posts: 2660

- Joined: Tue Aug 26, 2014 2:16 am

- Location: Emerald Isle

Re: need advice

Don't be a dick

Re: need advice

Looking like a fun project. I did the flat plate on my 3"-6" transition on my inline thumper and it works great for me. And I also use a copper plated SS canning funnel on my inline gin basket that also works a treat. As for drilling plates I take panhead screws and screw them down around the edges to hold the plates in place. Can't wait to see more progress and questions.

Life is a journey you take alone. Make sure you do what you what makes you happy

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

Re: need advice

I am hopping 7/64 is not to big

pretty much as far as i can go. I just ordered a bunch of copper fittings and tri clamps

i will get back on it n a few days when material arrives

still tryng to get my head wrapped around the cups...i do not like the idea on anything put copper being inside of the flute...I am thinking copper closet bolts for a toilet

pretty much as far as i can go. I just ordered a bunch of copper fittings and tri clamps

i will get back on it n a few days when material arrives

still tryng to get my head wrapped around the cups...i do not like the idea on anything put copper being inside of the flute...I am thinking copper closet bolts for a toilet

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

Re: need advice

pfshine wrote:Looking like a fun project. I did the flat plate on my 3"-6" transition on my inline thumper and it works great for me. And I also use a copper plated SS canning funnel on my inline gin basket that also works a treat. As for drilling plates I take panhead screws and screw them down around the edges to hold the plates in place. Can't wait to see more progress and questions.

splain that can to me please sir...type slow,

Re: need advice

Life is a journey you take alone. Make sure you do what you what makes you happy

Re: need advice

What are the flange bolts for? Is it for a plate tree?

Life is a journey you take alone. Make sure you do what you what makes you happy

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

Re: need advice

]yeah,but, i actually think i can just solder them instead of bolting

will this work ?

a pipe up thru the plate, cut on a 45, the bottom of the 45, 3/4'' above the plate

with a cap soldered to the top of the 45

will this work ?

a pipe up thru the plate, cut on a 45, the bottom of the 45, 3/4'' above the plate

with a cap soldered to the top of the 45

Re: need advice

Oh ok now I got ya. You can solder them on or you can also not use caps cut them at a slight angle and drop them to the next plate. The bath on that plate creates its own trap. As for them plate holes I'm sure they will work as od's first one had 1/8" holes I believe. But you will have to keep the heat on to make it work. Then again I'm a bubble cap guy so I could be talking out my backside.

Life is a journey you take alone. Make sure you do what you what makes you happy

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

Re: need advice

this does not seem right to me, 1/2'' [13mm] ID tube seems over kill for a 3'' flute.

will 3/8'' OD [ 10mm] be a better choice ? will it work?

Re: need advice

1/2 is the way to go to prevent flooding. I know it looks excessive but its not.

Life is a journey you take alone. Make sure you do what you what makes you happy

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

Re: need advice

then 1/2'' it will be thanks pfshine...

Re: need advice

The plates look a bit off. The downcomer should not be over any holes in this design. A very slight angle is all that is needed. Remember the liquid seal should be about as deep as the bath above it. Here is mt's thread on his build where the he started doing the downcomer that way. http://homedistiller.org/forum/viewtopic.php?t=24294

Life is a journey you take alone. Make sure you do what you what makes you happy

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

Re: need advice

, oh.....goody goody i get to make some more plates.

thanks for the link

thanks for the link

- cranky

- Master of Distillation

- Posts: 6516

- Joined: Fri Sep 27, 2013 3:18 pm

- Location: Pacific Northwest

Re: need advice

Can't you just solder a few holes shut?frodo wrote:, oh.....goody goody i get to make some more plates.

thanks for the link

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

Re: need advice

that was my plan. till he said the the angle on the down tube was to harsh

i already have 3 plates cut. but ran out of gass...

i already have 3 plates cut. but ran out of gass...

- frodo

- Distiller

- Posts: 1727

- Joined: Sat Dec 07, 2013 11:55 pm

- Location: hiding behind a pine tree. bout 100 miles east of new orleans

Re: need advice

holes under tube will be filled in...i cant believe i ran out of gas, i have 4 "B" tanks

all M/T

all M/T