Building a Controller Box

Moderator: Site Moderator

-

Ironheadchop

- Novice

- Posts: 24

- Joined: Sun Dec 22, 2019 9:45 am

Building a Controller Box

Hello all, i am almost finished gathering everything i need for my electric keg system and i am needing to make a controller box. I have searched around in here and looked at a few but still not sure which way to go. Not sure whether i need to go with 2 5500w elements or just 1. I was looking at some items on Auberins that i was thinking about using. If i used 2 elements would it be better to just use a controller for 1 and have the other on just an on/off switch to turn on just to get the unit to boil, then turn off and control temps with the element on the controller? I have a 100A sub panel i put in my garage when the house was built that i will be be coming off of. I ran wire to 3 outlets that i planned to use when i built another electric brew system. I cant remember the wire size that i ran to those outlets right off hand. I believe it is the same size i ran for the dryer and range outlets.. I will double check tonight.

The first one - https://www.auberins.com/index.php?main ... cts_id=332

If i used this what could i use the measure the power to the element with?

Second - https://www.auberins.com/index.php?main ... cts_id=559

With this one i was thinking i could just see the digital output readout?

If anyone has any tips/tricks/suggestions/insight/knowledge they would like to share it would be greatly appreciated. Thanks in advance.

The first one - https://www.auberins.com/index.php?main ... cts_id=332

If i used this what could i use the measure the power to the element with?

Second - https://www.auberins.com/index.php?main ... cts_id=559

With this one i was thinking i could just see the digital output readout?

If anyone has any tips/tricks/suggestions/insight/knowledge they would like to share it would be greatly appreciated. Thanks in advance.

- Yummyrum

- Global moderator

- Posts: 7743

- Joined: Sat Jul 06, 2013 2:23 am

- Location: Fraser Coast QLD Aussie

Re: Building a Controller Box

Auberins DSPR1

https://www.auberins.com/index.php?main ... cts_id=444

It says Wort boiling Controller but it is perfect still controller .

... simple power controller . 0-100% control. If you got 5500W element and it set to 25% power ... you got 1375W power ... can’t get simpler or more accurate than that

https://www.auberins.com/index.php?main ... cts_id=444

It says Wort boiling Controller but it is perfect still controller .

... simple power controller . 0-100% control. If you got 5500W element and it set to 25% power ... you got 1375W power ... can’t get simpler or more accurate than that

My recommended goto .

https://homedistiller.org/wiki/index.ph ... ion_Theory

https://homedistiller.org/wiki/index.ph ... ion_Theory

- Tummydoc

- Site Donor

- Posts: 967

- Joined: Tue Jun 24, 2014 1:05 pm

- Location: attack ship off the shoulder of Orion

Re: Building a Controller Box

What's the voltage of your outlets? If dryer outets with 240v you just need one element. Heat up time will be 45 min. Most that run 2 elements in a keg run 110 to each. 2 element on 110v 20 amp circuits is still less power than a single element on a 240v 30 amp circuit.

Last edited by Tummydoc on Wed Jun 24, 2020 4:43 am, edited 1 time in total.

-

Ironheadchop

- Novice

- Posts: 24

- Joined: Sun Dec 22, 2019 9:45 am

Re: Building a Controller Box

My sub panel is empty right now, No breakers yet as i have never needed them up until now. I have 3 outlets with either 10/3 or 6/3 ran to them( i cant remember now which size, and 3 110 outlets all in close proximity to each other on the back side of my garage wall. I can use any of those depending on what i go with.

- Tummydoc

- Site Donor

- Posts: 967

- Joined: Tue Jun 24, 2014 1:05 pm

- Location: attack ship off the shoulder of Orion

Re: Building a Controller Box

Go with 240, you won't regret having more power.

-

StillerBoy

- Master of Distillation

- Posts: 3387

- Joined: Thu Dec 01, 2016 6:27 pm

- Location: Ontario

Re: Building a Controller Box

That will all depend on how large the boiler is, and how fast of a warm up you want.. on a 15 gal keg with 12 gals warm up is about 20 min with 2 - 5500, and with only about double that.. a boiler load is never fully loaded as head space is always required for the foam that takes place depending on the wash/mash being stripped..Ironheadchop wrote: ↑Wed Jun 24, 2020 3:02 am Not sure whether i need to go with 2 5500w elements or just 1. I

Two element are good for warm up on stripping runs, not needed on spirit run, as the abv is quite higher that in a wash/mash, and heat up much faster..

If you are going for dual element, two separate plugs will be required..

Here a link to building a controller with dual potentiometer.. not all that difficult to put together..

viewtopic.php?f=85&t=51796

Mars

" I know quite certainly that I myself have no special talent. Curiosity, Obsession and dogged endurance, combined with self-criticism, have brought me to my knowledge and understanding "

– Albert Einstein

– Albert Einstein

-

NineInchNails

Re: Building a Controller Box

I prefer this EZboil and their 40A SSR even if you are going with 120V. That way you can run 240V any time in the future. Well worth the minor added cost.

That EZboil functions as variable and as a PID in a single unit. You can set temp alarms, it reads in 0.1F resolution, has the option for 2 relays for an optional buzzer/light which I prefer. I also use a small switch as an buzzer kill switch. I like to add an indicator light so it will show if/when the element is running.

Use RTD sensor because it is not compatible with K Type Thermocouples.

I like to use RTD panel mounts and plugs on the end of the RTD wire.

That EZboil functions as variable and as a PID in a single unit. You can set temp alarms, it reads in 0.1F resolution, has the option for 2 relays for an optional buzzer/light which I prefer. I also use a small switch as an buzzer kill switch. I like to add an indicator light so it will show if/when the element is running.

Use RTD sensor because it is not compatible with K Type Thermocouples.

I like to use RTD panel mounts and plugs on the end of the RTD wire.

Re: Building a Controller Box

Also if you need a wiring diagram the guys at Auberins will draw it up for you if you are buying their equipment.

-

Ironheadchop

- Novice

- Posts: 24

- Joined: Sun Dec 22, 2019 9:45 am

Re: Building a Controller Box

Looked at my box. The wire that we ran was 8/2 romex. Can that still be used for a 30 amp outlet?

- Tummydoc

- Site Donor

- Posts: 967

- Joined: Tue Jun 24, 2014 1:05 pm

- Location: attack ship off the shoulder of Orion

Re: Building a Controller Box

Yes that will be fine for 30 amps

- jonnys_spirit

- Site Donor

- Posts: 3667

- Joined: Wed Oct 21, 2015 7:58 am

- Location: The Milky Way

Re: Building a Controller Box

If you have the choice and funds now I’d go with two 5k5W elements both with power controllers so you can run both at lower power if desired to help prevent scorches. Plus you then have redundancy if they’re independent especially if you already have the breakers and romex pulled.

Might be considered overkill but that’s my contribution.

Cheers,

Jonny

Might be considered overkill but that’s my contribution.

Cheers,

Jonny

————

i prefer my mash shaken, not stirred

————

i prefer my mash shaken, not stirred

————

-

Ironheadchop

- Novice

- Posts: 24

- Joined: Sun Dec 22, 2019 9:45 am

Re: Building a Controller Box

Yeah i put 2 2" triclamp ferrules in my keg for 2 elements. I can do 1 to get me going then add the second. The outlets are only a few feet apart so have 2 different control boxes wont be an issuejonnys_spirit wrote: ↑Wed Jun 24, 2020 4:44 pm If you have the choice and funds now I’d go with two 5k5W elements both with power controllers so you can run both at lower power if desired to help prevent scorches. Plus you then have redundancy if they’re independent especially if you already have the breakers and romex pulled.

Might be considered overkill but that’s my contribution.

Cheers,

Jonny

Re: Building a Controller Box

Second - https://www.auberins.com/index.php?main ... cts_id=559

With this one i was thinking i could just see the digital output readout?

This is the unit I went with, with plenty of help from my son. Set it on mash to heat up to about 120-130 and switch over to per cent of power. Usually starting around 35%. I also have 240v in, but split it in 2 120v circuits, as I have 2 120v elements. I am very happy with this arrangement although I'm sure I'm not taking advantage of all of its capabilities.

pao

With this one i was thinking i could just see the digital output readout?

This is the unit I went with, with plenty of help from my son. Set it on mash to heat up to about 120-130 and switch over to per cent of power. Usually starting around 35%. I also have 240v in, but split it in 2 120v circuits, as I have 2 120v elements. I am very happy with this arrangement although I'm sure I'm not taking advantage of all of its capabilities.

pao

"Life is too short for cheap cigars"

-

Ironheadchop

- Novice

- Posts: 24

- Joined: Sun Dec 22, 2019 9:45 am

Re: Building a Controller Box

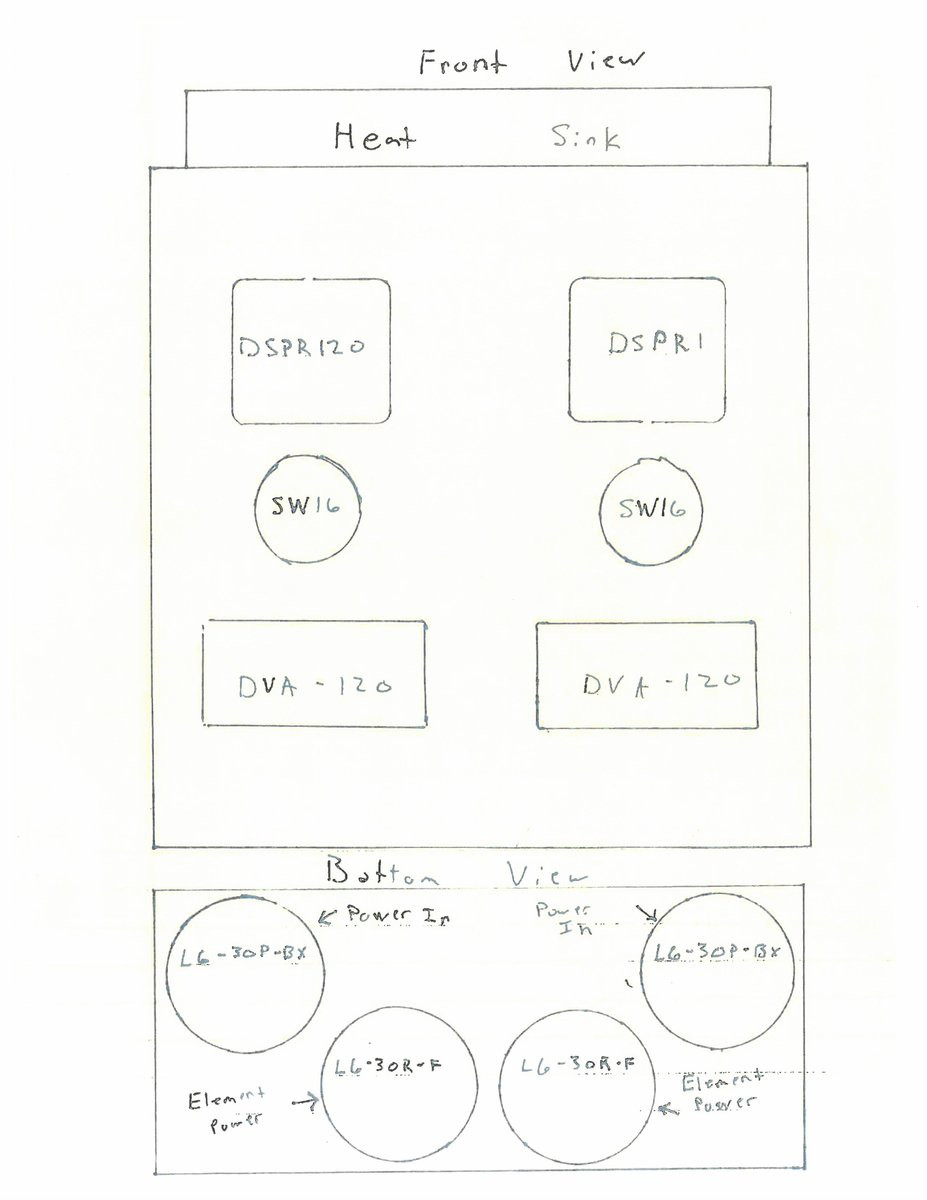

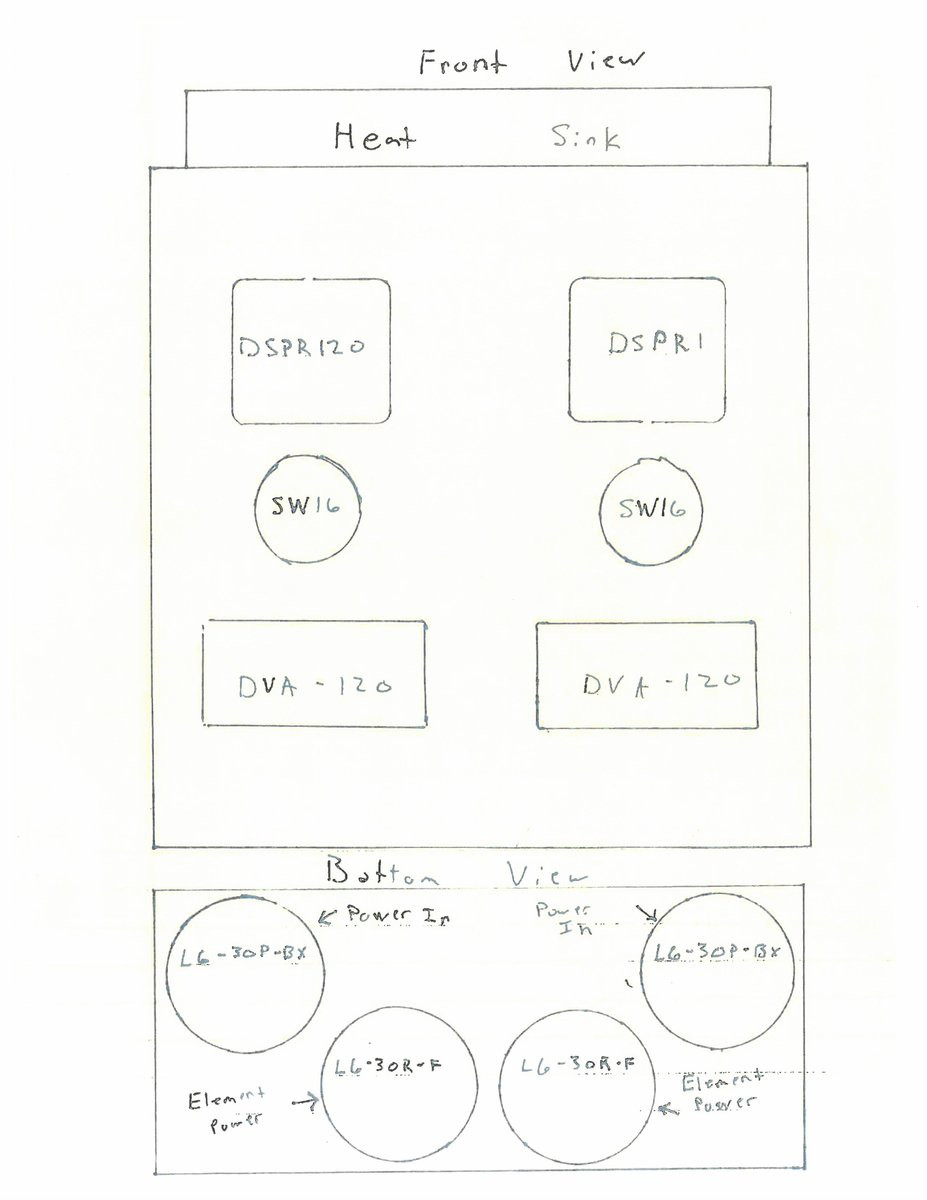

So i think i have come up with something that will work for me. Basically what i put together is 2 controllers in one box, one for each element since i dont have a 60A breaker to use yet. I have 2 30A outlets close together that i will use. Attached is a picture of my design. I will use an ezboil for my main element and then just a standard controller for the other. I like the ezboil having the readout for a thermometer if i ever choose to use it later down the road. Using selector switches to power elements on and off. I will use a voltmeter/ammeter for a readout just cause i like to look at numbers. The elements i bought have the prongs to attach a L6-30R plug directly to the element, so i will make up a twist lock cord that goes from the element to the bottom of the box. As for power i will make a twist lock cord to run tho the power plug for each element.

- Danespirit

- Site Donor

- Posts: 2647

- Joined: Tue Dec 25, 2012 8:09 am

- Location: Denmark

Re: Building a Controller Box

Well, without knowing your boiler size I assume it's a big m.... with two 5,5 KW elements in it.

You could also take the easy route and go for an SCR (or two if you like to control every element separately).

You can find them dirt cheap on eBay.

Buy one a little over-dimensioned to be on the safe side.

Mine is a 5 Kw (see picture) one that runs a 2 KW element. It cost me about 6 $ if I remember correctly.

I'm pretty sure you can get one that runs 110V too.

Then it's just simple plug and play...unless you want to add a few bells and whistles like amp gauge or the like.

You could also take the easy route and go for an SCR (or two if you like to control every element separately).

You can find them dirt cheap on eBay.

Buy one a little over-dimensioned to be on the safe side.

Mine is a 5 Kw (see picture) one that runs a 2 KW element. It cost me about 6 $ if I remember correctly.

I'm pretty sure you can get one that runs 110V too.

Then it's just simple plug and play...unless you want to add a few bells and whistles like amp gauge or the like.

- still_stirrin

- Master of Distillation

- Posts: 10344

- Joined: Tue Mar 18, 2014 7:01 am

- Location: where the buffalo roam, and the deer & antelope play

Re: Building a Controller Box

Ironhead, it looks a lot like mine:Ironheadchop wrote: ↑Tue Jun 30, 2020 9:49 am So i think i have come up with something that will work for me....

Like yours, I run two separate power circuits (separate household breakers) on 120VAC. Using the 4500 watt 240 volt elements, it draws just short of 10 amps per side, so it is safe on my household wiring. To start, I turn them both wide open, but then dial back as I’m nearing production. Since the elements are both ULWD elements running on 1/4 power, it almost guarantees I won’t scorch. I use the ammeters to indicate the “relative power” input, as the voltmeters show very little drop in the typical operating range. As a result, the current draw is proportional to power input.

My circuits are both SCR circuits designed from the Littelfuse cutsheet outlined in Rad’s control circuit (see the epic electrical build thread for details). I have heatsinks on each of the Triacs and a fan draws air across them.

I like having two controller circuits for my boiler and they fit comfortably inside the box, although I couldn’t “shoehorn” the fan inside.

ss

My LM/VM & Potstill: My build thread

My Cadco hotplate modification thread: Hotplate Build

My stock pot gin still: stock pot potstill

My 5-grain Bourbon recipe: Special K

My Cadco hotplate modification thread: Hotplate Build

My stock pot gin still: stock pot potstill

My 5-grain Bourbon recipe: Special K

-

Ironheadchop

- Novice

- Posts: 24

- Joined: Sun Dec 22, 2019 9:45 am

Re: Building a Controller Box

Yeah man i dig it. Thats pretty much what im going for except with digital readouts. Although it would be pretty cool to watch the needle bounce around.

- Oldvine Zin

- Site Donor

- Posts: 2416

- Joined: Sat Jun 06, 2015 9:16 pm

- Location: Pacific Northwest

Re: Building a Controller Box

Analog meters don't bounce around as much as the digital ones doIronheadchop wrote: ↑Wed Jul 01, 2020 2:05 amYeah man i dig it. Thats pretty much what im going for except with digital readouts. Although it would be pretty cool to watch the needle bounce around.

OVZ

- still_stirrin

- Master of Distillation

- Posts: 10344

- Joined: Tue Mar 18, 2014 7:01 am

- Location: where the buffalo roam, and the deer & antelope play

Re: Building a Controller Box

OVZ is absolutely correct. The needles are quite steady and very easy to see throughout the run. It just takes a glance at the gages to see.Oldvine Zin wrote: ↑Tue Jul 07, 2020 8:08 pmAnalog meters don't bounce around as much as the digital ones doIronheadchop wrote: ↑Wed Jul 01, 2020 2:05 amYeah man i dig it. Thats pretty much what im going for except with digital readouts. Although it would be pretty cool to watch the needle bounce around.

OVZ

I much favor the analog gages over digital readouts for a couple of reasons: 1) easy and quick visualization of input power, 2) stable operation, and 3) more robust than a quirky digital display.

As I said, I don’t really need to know the “watts” of input heat, just the “relative input”, which is easy to see with the current gage. I simply adjust the amps to regulate the vapor production as needed (if and when needed).

I don’t even need the voltmeters and they could have been omitted from the design, but I added them because I had them. With the Triac circuit, the voltage doesn’t drop below 110V until the current flow is well below 5 amps, and I typically run the 4500W/220V elements at 6 to 9-1/2 amps on 120VAC. It gives plenty of control for the vapor production rate for the potstill head or the LM or VM reflux head operation.

Of note, with reflux operation, I typically keep the current higher so I get more reflux, ie - more vapor going up the column and condensing back, then reboiling in the packing as the heat exchange occurs in the column.

ss

My LM/VM & Potstill: My build thread

My Cadco hotplate modification thread: Hotplate Build

My stock pot gin still: stock pot potstill

My 5-grain Bourbon recipe: Special K

My Cadco hotplate modification thread: Hotplate Build

My stock pot gin still: stock pot potstill

My 5-grain Bourbon recipe: Special K

-

Big Stogie

- Swill Maker

- Posts: 255

- Joined: Thu Mar 15, 2012 9:39 am

Re: Building a Controller Box

Auber has an actual still controller that works great https://www.auberins.com/index.php?main ... cts_id=559

-

NineInchNails

Re: Building a Controller Box

Don't forget RTD sensor panel mounts & RTD sensors. You'll be needing one for each controller. Just know, they are 6' long. If you want longer cords, you can buy RTD wire to extend them.