You need a normaly open on button that energize a power relay with a take over contact, stop button and pressure switch etc. are normally closed contacts. My experience with this type of protection is when they protect to often they often got bridged. I agree that the best thing is not to choke the column.Jacksonbrown wrote:This could work but the switch would also have to be latching otherwise the cut in power would lower the pressure and it would just turn on again. It would also mean a restart every time it tripped which would be a right PITA if it was a bit finicky.

I will give it some more thought but I think the solution is just don’t choke the column.

A feed of about 22 °C would give the measured temperature. A feed concentration of 8,5 % ABV would produce the same distillate temperature and lower the distillate concentration to 51% ABV and the distillate flow of 42 ml/min which is more in line with my calculations.Jacksonbrown wrote:5° or 6° more in the feed would account for 40° difference in the distillate temp, yes?

I can't explain the overall lower distillate concentration by inefficient packing. Inefficient packing would mean that steam is diluting your distillate but would also mean that you should get more distillate then measured. This would also mean that you need more power which would also raise the distillate temperature. And I don't see this in the numbers.

I think that you are getting so close to what is possible that the you need to take a lot more accurate measurements. The stopwatch and by the looks of it the temperature probes are ok, instead of a measuring jug I would recommend a digital kitchen scale and weight the output as this will cancel out any temperature influences. Compensate the boiler temperature for the barometric pressure and get something to accurately measure your feed concentrationJacksonbrown wrote:Keep in mind that a stop watch, measuring jug and 0 to 100 alcometer are hardly high precision instruments and I’m getting my feed rate by adding the two outputs.

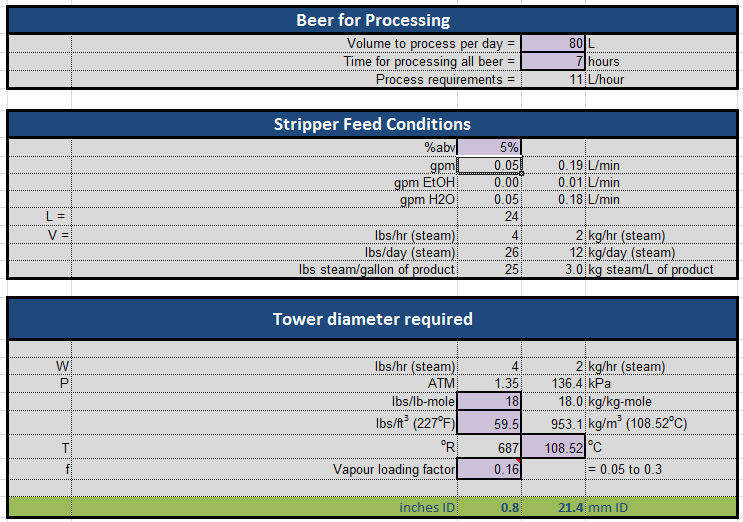

Based on your numbers and my calculations I would say that for a continuous stripper cooled by the feed:Jacksonbrown wrote:You say I may have reached the theoretical limits of your system but I want to know what all the parameters are and what effect they have.

Higher feed temperature will produce higher distillate temperature. A small variation in feed temperature will have a much larger influence on the distillate temperature. best stay below 24 °C

Higher feed concentration will produce higher distillate temperature. Best stay below 10% ABV or compensate with colder feed.

More feed means more heating power. I think the limit will be the packing.

I still think you have to much packing, try 30 cm and see what the numbers are. You could also try lava rock.