This has probably been discussed before but I couldn't find it.

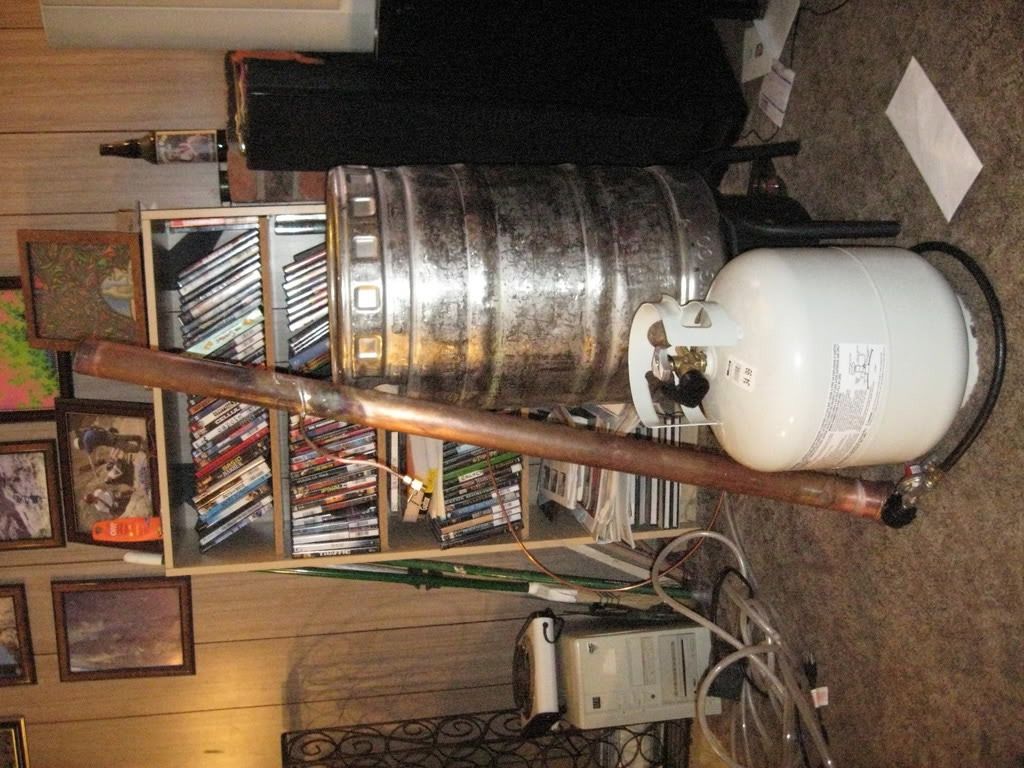

Is one design better overall than the other in any significant way? I am looking at building one of the two models I found at:

moonshine-still.com/page2.htm

Has anyone here constructed either one from these plans? How did it go? Any better plans out there?

From what I understand (or think I do) the reflux rate in the internal is controlled by the amount and temperature of the coolant, and the valved is controlled by restricting the exhaust. I may be completely wrong too. Tell me if I am please.

I'm leaning toward the valved design at this point. Mainly because it has knobs and looks cool.

My main considerations are:

Is there any danger of the valved design building enough internal pressure to rupture the containment vessels (if it does in fact operate in the manner I imagine) during normal operation?

Is one easier to operate? More sensitive, or easier to regulate and maintain a constant temperature?

Is using silver solder a skill that is difficult to teach one's self?

Does it really matter which I make?

Any comments would be welcome. Tell me what to do and I'll go blow $$ on copper tubing:)

Hello. Good to be here,

Skymeat