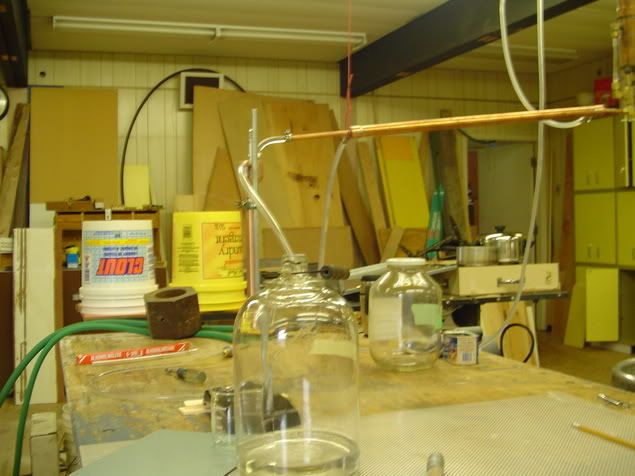

We made the condenser coil removeable for cleaning purposes. You simply just drop it in the top and hook up the water.

Next we added a sight glass near the needle valves for reflux and output. We find this feature very handy for monitoring the amount of alcohol being refluxed. It gives you a window to see whats happening how fast it's coming off etc. The way we've been running it is we set the output at a steady rate, collecting about 100ml in 4 minutes. then we adust the reflux to keep a constant level in the sight glass (ie: not gaining or losing)

Most runs the output needle valve is opened about 1/8 of a turn and the reflux is opened about 3/4 of a turn. During the middle of the run we've been getting a consistant 88% product.

We recently added a secondary cooler. After the cooling water runs through the condenser coil it runs through another cooling tube on the output. Coming off of the output valve is a 1/4" copper tube which the alcohol runs through, this tube runs through a 1" copper pipe which water is circulated through. The purpose of this cooler is to get the temperature of the product down to about 20 deg C so the product can be acurately monitored for alcohol %.

Then after the secondary or output cooler we have a copper testing chamber in which the alcohol meter floats thoughout the entire run. The product comes into the bottom and flows out the top into a collection jug.

We used the stainless mixing bowl idea in the plan to connect the column to the beer keg and used a coupler off of an old fire extinguisher to join the column to the bowl. This coupler has an o-ring fitting and is easily attatched or detached.

And finally the heat source. Good ole propane, Hank Hill would bevery proud. We can't be bothered futsin' around with electric heater elements. Propane is so easy to control and responds right now

That's about it. We've run about 10 washes through it now, with good results. Comments? Questions?