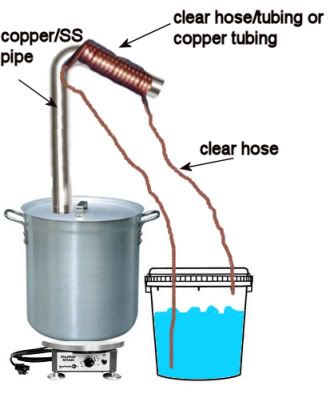

cut and pasted a bunch of stuff together for a general idea...

1. A stainless steel stock pot

2. Copper/SS pipe - 2 Feet with 1 foot condensor piece

3. Electric hot plate - I want to use a smooth flat one as opposed to the coil type - instead of a water jacket (too hard for me lol)

4. I want to use either copper tubing wrapped around the pipe, or clear flimsy type rubber hose that can easily be compressed and wrapped around the pipe, which will use water from a 5 gallon bucket (blocks of ice in it probably) and a fish tank pump or something.

the lid of the stock pot will be either held on with clamps like these -

with a cork seal, or some other kind of clamp, if worse comes to worse I will drill holes around the lip and lid and install somesthing like these

so you only need to use wingnuts to tighten the lid down

my many questions -

1. Using ice water will obviously cause heavy condensation on the pipe, will this be an issue with it running down into the collector?

2. Will room temp water be good enough if ice is too cold?

3. Alcohol boils at 78.3C which is 173F, this will be very tricky - is it ok to just get the mash to a point just below boiling, like a very small rolling boil where you would just see little bubbles coming from the bottom of the pot if you cannot get exactly 173F ?

4. I want to have the column offset to the left a bit to stabilize the weight, is it ok if it is not in the center of the top?

5. Most important - how do you know when you have distilled all of the alcohol ?

thanks guys for any help, I appreciate it.