Crossflow Condenser - has anyone built one?

Moderator: Site Moderator

Crossflow Condenser - has anyone built one?

I am planning on building a reflux still and I need to decide between an offset head with a coiled condenser and a crossflow condenser.

Has anyone on this forum built a crossflow? Is there any reason not to build a crossflow?

Thanks for your responces.

Nathan

Has anyone on this forum built a crossflow? Is there any reason not to build a crossflow?

Thanks for your responces.

Nathan

-

birdwatcher

- Swill Maker

- Posts: 387

- Joined: Mon Oct 09, 2006 7:27 am

- Location: Ontario

Crossflow Condenser - has anyone built one?

Hi,

Sorry, I don't know what a crossflow condenser is, however I built and have been using a reflux still following the directions found in a book by Dr. John Stone. http://www.gin-vodka.com" onclick="window.open(this.href);return false;" rel="nofollow. Making Gin and Vodka.

Ten years of trouble free operation, producing 95% ethanol, which does not require filtration with charcoal,

You can't go wrong with this design or his instructions.

Good luck.

George

Sorry, I don't know what a crossflow condenser is, however I built and have been using a reflux still following the directions found in a book by Dr. John Stone. http://www.gin-vodka.com" onclick="window.open(this.href);return false;" rel="nofollow. Making Gin and Vodka.

Ten years of trouble free operation, producing 95% ethanol, which does not require filtration with charcoal,

You can't go wrong with this design or his instructions.

Good luck.

George

My sugar wash for ethanol is under the Tried and true recipes forum.

-

Stillhead

If by crossflow condenser you mean a jacketed column condenser, then you should check out the site on 'Building a Home Distillation Apparatus'. I was originally going to follow this plan for the condenser, but chose an internal coil design because I could not gather all the fittings for cheap.

I ended up using a 2" pipe with 20ft of 1/4" tubing bent into a coil. I then slid the coil into the pipe and used 90degree elbow compression fittings to attach through the condenser wall.

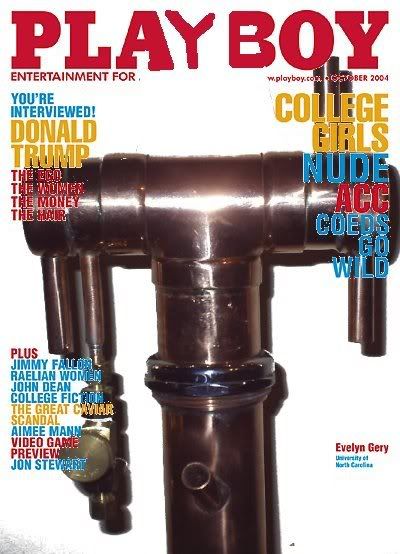

Here's what it looks like:

I ended up using a 2" pipe with 20ft of 1/4" tubing bent into a coil. I then slid the coil into the pipe and used 90degree elbow compression fittings to attach through the condenser wall.

Here's what it looks like:

Crossflow condensor = shotgun condensor, right?

From my understanding, the difference between the coil condensor and the crossflow condensor is that the coil requires a small amount of fast-moving water (high pressure) and the crossflow requires a larger amount of slow moving water (low pressure). So if you are plugging into your city water spigot for cooling water, then you would probably take the coil. If you are recirculating water with a cheap pump then you would take the crossflow.

From my understanding, the difference between the coil condensor and the crossflow condensor is that the coil requires a small amount of fast-moving water (high pressure) and the crossflow requires a larger amount of slow moving water (low pressure). So if you are plugging into your city water spigot for cooling water, then you would probably take the coil. If you are recirculating water with a cheap pump then you would take the crossflow.

Thanks for the comments stillhead and masonjar. I guess I should have been more specific.

I'm trying to decide between a valved reflux from moonshinestill.com

and Harry J's crossflow head

The crossflow head seems like a good idea, I was just wondering if anyone had tried it. I plan on recirculating the water. I will probably add a second needle valve for reflux to the center of the column just above the packing. Thanks.

I'm trying to decide between a valved reflux from moonshinestill.com

and Harry J's crossflow head

The crossflow head seems like a good idea, I was just wondering if anyone had tried it. I plan on recirculating the water. I will probably add a second needle valve for reflux to the center of the column just above the packing. Thanks.

-

junkyard dawg

- Master of Distillation

- Posts: 3086

- Joined: Fri Feb 03, 2006 11:40 am

- Location: Texas

-

copperhead

- Swill Maker

- Posts: 244

- Joined: Thu Jan 26, 2006 4:52 pm

- Location: nc

-

Rudi

- Rumrunner

- Posts: 518

- Joined: Mon Nov 06, 2006 3:27 am

- Location: 50 miles past kikatinalong up that dirt track

Hi redbeard as far as i can see the crossflow condensor is a very good design just looks like it would take a little more time and skill to fabricate it is good in that it doesnt restrict water flow and enables you to use a low pressure high volume pump (read cheaper) to circulate coolant. I am in the process of building a valved reflux still and have just bent up a 12inch double helix coil it used 9 meters of 6mm od soft copper and after hooking it up to my water supply for a test it presents quite a restriction it will be interesting to see how it performs I may have to reduce it a little I chose the valved reflux so I could remove the packing and run as a pot still good luck with your choice

Such is life

-

hornedrhodent

- Rumrunner

- Posts: 732

- Joined: Sat Mar 04, 2006 1:42 am

- Location: Nth coast NSW

="masonjar"

Crossflow condensor = shotgun condensor, right?

From my understanding, the difference between the coil condensor and the crossflow condensor is that the coil requires a small amount of fast-moving water (high pressure) and the crossflow requires a larger amount of slow moving water (low pressure). So if you are plugging into your city water spigot for cooling water, then you would probably take the coil. If you are recirculating water with a cheap pump then you would take the crossflow.

A crossflow condenser is not quite the same as a shotgun condenser. In the shotgun the vapour is going through the tubes and the water outside. The crossflow has the water going through the tubes and the vapour condensing on the outside of them.

Both have the advantage of allowing a high volume water flow and a large surface area for the distillate to condense on in a small package.

I have just finished building that exact design of crossflow condensor. It's not that complicated, just a little tricky to put the end caps on with all the cooling pipes. Achieved 95% in the first run. Very happy with the result and you can run it quite fast even on a 2" column.

Never do tomorrow what you can do today because if you like what you do today you can do it AGAIN tomorrow!

-

Uncle Jesse

- Site Admin

- Posts: 3935

- Joined: Wed Apr 21, 2004 3:00 pm

well

it really depends what you're trying to do. if you want neutral spirits, the crossflow will probably do that pretty effectively. if you're doing spirits which rely on the mash for flavor then you won't want something quite so efficient.

If only the best birds sang, the woods would be silent.

-

Harry

- Swill Maker

- Posts: 198

- Joined: Sun Jan 30, 2005 7:46 pm

- Location: Paradise (aka Cairns Qld Australia)

it really depends what you're trying to do. if you want neutral spirits, the crossflow will probably do that pretty effectively. if you're doing spirits which rely on the mash for flavor then you won't want something quite so efficient.

UJ, I could be wrong but I get the impression that some folk think the term 'crossflow' refers to the entire still rig. NOT SO!

The crossflow is a condenser, nothing more. Although it's an extremely efficient condenser for its size. Neutral spirit or otherwise is a function of the column and packing. It's all about separation capability.

The condenser's function is to knock down the vapor. If the condenser is inefficient, you'll lose vapor, and therefore yield. If the condenser is super-efficient, it won't do anything more than knock down vapor. It does NOT strip flavors.

Yes you can easily make flavored type spirits with a crossflow condenser and column, just as you can with an overhead coil or N/S offset head. Simply remove the column packing and open up fully the product valve. Then the rig has little or no separating capability, just like a potstill. One strip run, then a second product run, and you have your whisky @ 75-80% abv.

Slainte!

regards Harry

ps

Hackers...care to post a pic or two of yours? As the original developer of this condenser, I'm always interested to see how people go with the build.

H

-

Uncle Jesse

- Site Admin

- Posts: 3935

- Joined: Wed Apr 21, 2004 3:00 pm

understood

he said his crossflow was giving 95% ABV. that's impressive. my column whiskey still never gave me anything better than 86% ABV. 95% is a bit too efficient for my tastes as I don't prefer vodka and I don't dabble with essences and flavors.

If only the best birds sang, the woods would be silent.

-

Harry

- Swill Maker

- Posts: 198

- Joined: Sun Jan 30, 2005 7:46 pm

- Location: Paradise (aka Cairns Qld Australia)

Yes I know that's what he said. That's why I posted, just to clarify it's not the condenser doing that, it's the reflux column.he said his crossflow was giving 95% ABV

Potstills do one distillation/separation per pass, columns with packing and refluxing do multiple distillations/separations per pass. Heat losses, packing type , column length, operating methods etc., will determine just how close you get to the azeotrope (95.6%). These inefficiencies can sometimes work in your favour, and you'll get less than azeotrope, like your 86% (I'm assuming when you said 'my column' you meant a reflux column). That's similar to deliberate 'de-tuning'.my column whiskey still never gave me anything better than 86% ABV.

Slainte!

regards Harry

regards Harry

-

Harry

- Swill Maker

- Posts: 198

- Joined: Sun Jan 30, 2005 7:46 pm

- Location: Paradise (aka Cairns Qld Australia)

Hi Redbeard,

I'm pleased you chose the crossflow design. Very good for closed coolant systems. It's been build many times around the world now. All reports I've had so far, all are happy. A couple of points to help you...

1) MAKE SURE you use different melting point solders/brazes. The pipe ends to plates joins MUST BE the higher temp filler. Otherwise you'll undo the joints and have internal leakage into your product. Use the lower temp filler for the other bodywork.

2) Read the pdf on my website. Go by those steps and you'll be fine. DO TEST for leaks BEFORE you add the endcaps. It's bloody hard to fix it later...requires cutting off the caps, fixing the leaks, then re-doing the caps.

3) DO NOT add a redirect valve for reflux to packing centre. Not necessary. If you do, you'll introduce vapor pressure into the takeoff tube (unless you vapor-lock it with a U-bend). The result will be a flooding head. Reflux is automatically returned via dam wall overflow caused by takeoff valve adjustment (balance between quantity of takeoff & reflux).

This design DOES NOT require central positioning of reflux. That's a furphy. Reflux will revaporize the moment it finds the necessary temp gradient down the column length to do so, whether the reflux is so-called 'sheeting, channeling' or not (pack the column better!). Also, the packing strands are in contact with the column wall at all points, providing drainage of droplets back into the packing, just like raindrops draining along twigs & branches. Many tests have proved this to be the case. If in doubt, pack a glass column and see for yourself.

(I bet this buys arguments. People's favorite Myths are hard to destroy. Loch Ness, Bigfoot, reflux sheeting...)

Lastly, Good Luck with the project. Looking forward to the pics.

I'm pleased you chose the crossflow design. Very good for closed coolant systems. It's been build many times around the world now. All reports I've had so far, all are happy. A couple of points to help you...

1) MAKE SURE you use different melting point solders/brazes. The pipe ends to plates joins MUST BE the higher temp filler. Otherwise you'll undo the joints and have internal leakage into your product. Use the lower temp filler for the other bodywork.

2) Read the pdf on my website. Go by those steps and you'll be fine. DO TEST for leaks BEFORE you add the endcaps. It's bloody hard to fix it later...requires cutting off the caps, fixing the leaks, then re-doing the caps.

3) DO NOT add a redirect valve for reflux to packing centre. Not necessary. If you do, you'll introduce vapor pressure into the takeoff tube (unless you vapor-lock it with a U-bend). The result will be a flooding head. Reflux is automatically returned via dam wall overflow caused by takeoff valve adjustment (balance between quantity of takeoff & reflux).

This design DOES NOT require central positioning of reflux. That's a furphy. Reflux will revaporize the moment it finds the necessary temp gradient down the column length to do so, whether the reflux is so-called 'sheeting, channeling' or not (pack the column better!). Also, the packing strands are in contact with the column wall at all points, providing drainage of droplets back into the packing, just like raindrops draining along twigs & branches. Many tests have proved this to be the case. If in doubt, pack a glass column and see for yourself.

(I bet this buys arguments. People's favorite Myths are hard to destroy. Loch Ness, Bigfoot, reflux sheeting...)

Lastly, Good Luck with the project. Looking forward to the pics.

Slainte!

regards Harry

regards Harry

Harry wrote:Hi Redbeard,

This design DOES NOT require central positioning of reflux. That's a furphy. Reflux will revaporize the moment it finds the necessary temp gradient down the column length to do so, whether the reflux is so-called 'sheeting, channeling' or not (pack the column better!). Also, the packing strands are in contact with the column wall at all points, providing drainage of droplets back into the packing, just like raindrops draining along twigs & branches. Many tests have proved this to be the case. If in doubt, pack a glass column and see for yourself.

(I bet this buys arguments. People's favorite Myths are hard to destroy. Loch Ness, Bigfoot, reflux sheeting...)

Lastly, Good Luck with the project. Looking forward to the pics.

As far as I know it, this only applies to columns of certain diameter. In practise the max. diameter where this work properly is ~2". As the vapor moves up the column it tends to "push" liquid flow towards the column walls. As you described small diameter columns are not affected much by this, but when you move to 3" or 4" diameter the efficiency starts to drop markedly as there will be a reflux concentration near the walls while the middle has very little liquid providing easy rising path for vapors. This in turn decreases column efficiency, increases theoretical HETP in lower parts and causes cancer, plague and famine.

This is how I understand it currently, do chime in if you have more data or insights.

Cheers, Riku

Hi Harry you are absolutely 100% right, the 95% ABV is a result of the column, let's just put it down to typing after a few too many rumsHarry wrote:he said his crossflow was giving 95% ABV

Yes I know that's what he said. That's why I posted, just to clarify it's not the condenser doing that, it's the reflux column.

I should have some pics for of the condensor in the next couple of weeks.

Cheers

Never do tomorrow what you can do today because if you like what you do today you can do it AGAIN tomorrow!

-

Vickypoint

- Novice

- Posts: 10

- Joined: Sat Jul 30, 2005 7:18 pm

- Location: By the seaside in Oz

Harrys cross flow design I built

I have posted a picture of Harry's design crossflow which I built. I have found it to be a great design. I have a 1.5 mt long packed 50mm copper column, filled with stainless scrubbers. I get 95% out of it. It is a very economical still to run as I recycle water from a 200 litre plastic drum which uses a 500 lph pond pump to recirculate the water and it has a great water flow. No trouble keeping it cool.

I would recommend this design to any intending builder.

Vickypoint.

I would recommend this design to any intending builder.

Vickypoint.

-

saltyassdog

- Novice

- Posts: 6

- Joined: Wed Jun 06, 2007 4:46 pm