Agreed, the only ones who will end up ahead are youre friends and family who no longer have to buy piss. You will end up spending more and more on your little 'hobby' in search of perfection (assuming you're anything like most round here)Rudi wrote:Pita wrote:at least this one will actually pay for itself - and very fast.

)

Yeah good luck with that

Practice mash in the making. + Still questions

Moderator: Site Moderator

-

punkin

- Master of Distillation

- Posts: 2711

- Joined: Fri Oct 05, 2007 12:36 pm

- Location: Northern NSW Oz Trail Ya

Re: Practice mash in the making. + Still questions

Re: Practice mash in the making. + Still questions

Haha. Very true. I'm constantly building, designing, and making things better. Most I can't afford so I just draw them outpunkin wrote:Agreed, the only ones who will end up ahead are youre friends and family who no longer have to buy piss. You will end up spending more and more on your little 'hobby' in search of perfection (assuming you're anything like most round here)Rudi wrote:Pita wrote:at least this one will actually pay for itself - and very fast.

)

Yeah good luck with that

I am nothing but a fictional character. All I say should be treated as such- as it is only to make me look cool.

Re: Practice mash in the making. + Still questions

I finally found a place that I can buy by the foot for tubing.  They would have to order it, but they'll still sell it to me by the foot. It was 6 or 8 bucks a foot for 1 1/2" pipe. I have two questions regarding that - Which class do I want? I think they said the could get L or M. Also, how long should I make the pot still column?

They would have to order it, but they'll still sell it to me by the foot. It was 6 or 8 bucks a foot for 1 1/2" pipe. I have two questions regarding that - Which class do I want? I think they said the could get L or M. Also, how long should I make the pot still column?

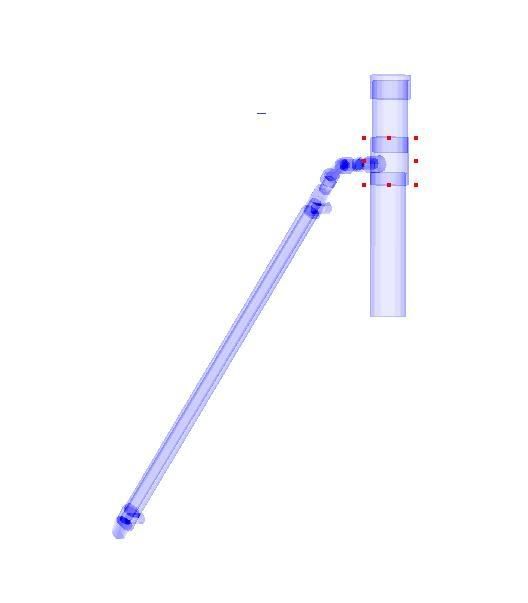

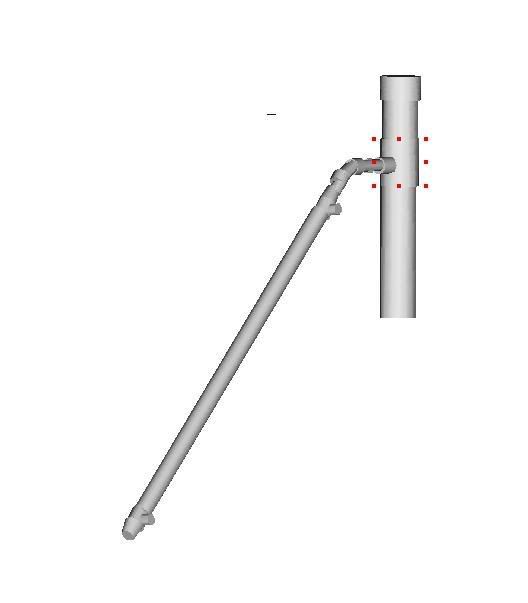

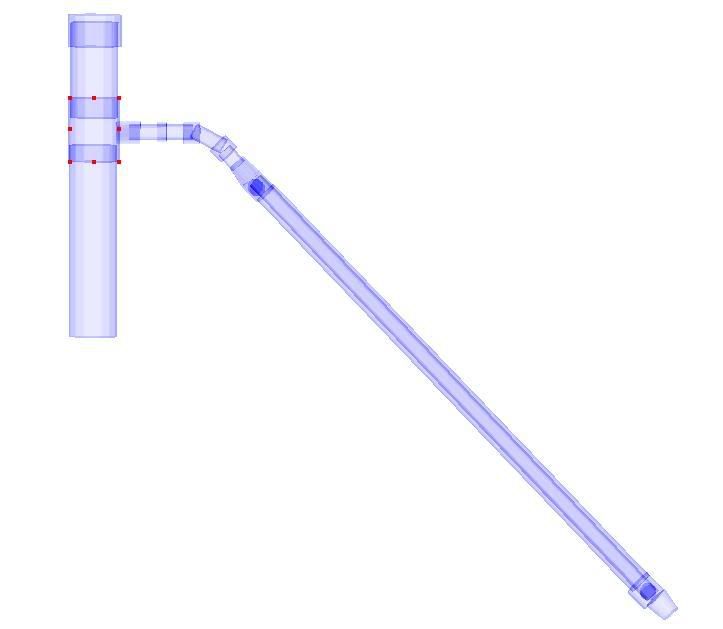

I found some 3-D modeling software that I drew up a pot still to scale in. The software is a pain. I don't know if I can export the file in the right format to post up here, but I'll try that right now. It's pretty nifty

I found some 3-D modeling software that I drew up a pot still to scale in. The software is a pain. I don't know if I can export the file in the right format to post up here, but I'll try that right now. It's pretty nifty

I am nothing but a fictional character. All I say should be treated as such- as it is only to make me look cool.

Re: Practice mash in the making. + Still questions

I'm going to use Hawke's suggestion on the sizing.

Everything should be relatively to scale. The pipe parts are definitely, but the couplings are guestimated. The column is made of an undecided length of 1 1/2" copper. The T is 1 1/2 x 1 1/2 x 1/2 (actually - I based that part off a 1x1x1/2, so I'll probably need to do a step down.). the 1/2" meets a 1/2" disconectable union and then a 45* bend. That connects to my poorly drawn up 3/4x1/2x1/2 T. The 1/2" is inside the 3/4" liebig (36") with another T at the end.

How's it lookin'?

I am nothing but a fictional character. All I say should be treated as such- as it is only to make me look cool.

-

bluemike807

- Novice

- Posts: 6

- Joined: Tue Jul 15, 2008 5:48 am

Re: Practice mash in the making. + Still questions

Im curious, you've mentioned using a water-heater element internal to you boiler. What's the best way to install something like that (especially given your lack of welding equipment)?

Also, once its physically installed, how do you setup power to it - in such a way as you can regulate temperature (assuming you would do so through regulating the current to the element).

Also, once its physically installed, how do you setup power to it - in such a way as you can regulate temperature (assuming you would do so through regulating the current to the element).

-

theholymackerel

- retired

- Posts: 1432

- Joined: Fri Oct 22, 2004 7:39 pm

Re: Practice mash in the making. + Still questions

You don't "run a still" at any certain temperature. Ya provide steady, even heat, and the still comes to an equilibrium and sets it's own temp. The temp also will rise throughout the run... this is more noticable on a potstill, but reflux columns do it too.bluemike807 wrote:how do you setup power to it - in such a way as you can regulate temperature

The important thing to takeaway from this is "steady, even heat".

I wish ya luck.

Re: Practice mash in the making. + Still questions

Well, there are two different kinds of heating elements at the store by me. One of them screws into a water heater - it is threaded. The other type is a bolt in (inside and outside). However, at least at this particular store, it only comes in 3800 watts. I haven't looked into it much more than that since I'm going to get the hang of a stove powered still before I start playing with variables that have a huge impact. What I do know is how you get, and regulate power to it. The power chord connects to the element via its screw-able terminals. It then connects to a water heater controller, some more wire, and a plug. And there you have it. I would think you could use a simple dimmer switch or a reptile rheostat instead.bluemike807 wrote:Im curious, you've mentioned using a water-heater element internal to you boiler. What's the best way to install something like that (especially given your lack of welding equipment)?

Also, once its physically installed, how do you setup power to it - in such a way as you can regulate temperature (assuming you would do so through regulating the current to the element).

Here's a link to a screw in type water heater element. I think I saw a nut that would fit on it as well; might be able to use that too and tighten it real good as there is a seal on the outside. http://farmandfleet.com/catalog/product ... =050401004" onclick="window.open(this.href);return false;" rel="nofollow

Btw, I don't mean to be pushing farm and fleet. It's just one of the few stores' sites that actually have the parts AND prices.

Hopefully that helped answer your questions a little.

Pita

I am nothing but a fictional character. All I say should be treated as such- as it is only to make me look cool.

Re: Practice mash in the making. + Still questions

Eaarlier you had mentioned getting cracked corn for $10 for 10 lbs. Find a Feed Store. You should be able to get 50 Lbs. for under $10.

For instructions on winding a coil read this Sticky http://homedistiller.org/forum/viewtopic.php?f=2&t=6140. Don't wind without it.

For instructions on winding a coil read this Sticky http://homedistiller.org/forum/viewtopic.php?f=2&t=6140. Don't wind without it.

Never refuse to do a kindness unless the act would work great injury to yourself, and never refuse to take a drink-- under any circumstances.

- Mark Twain's Notebook

- Mark Twain's Notebook

Re: Practice mash in the making. + Still questions

Haha, I didn't think anyone caught that. They are actually 50lb bags. The store caters to farmers - they have posted per ton pricingOaty wrote:Eaarlier you had mentioned getting cracked corn for $10 for 10 lbs. Find a Feed Store. You should be able to get 50 Lbs. for under $10.

For instructions on winding a coil read this Sticky http://homedistiller.org/forum/viewtopic.php?f=2&t=6140. Don't wind without it.

Thanks for the tips!

Pita

I am nothing but a fictional character. All I say should be treated as such- as it is only to make me look cool.

Re: Practice mash in the making. + Still questions

A ton might take the whole weekend. Don't ya think?

Never refuse to do a kindness unless the act would work great injury to yourself, and never refuse to take a drink-- under any circumstances.

- Mark Twain's Notebook

- Mark Twain's Notebook

Re: Practice mash in the making. + Still questions

Then we could have a homedistiller.org BBQ and see if we can't make it disappear just as fast!Oaty wrote:A ton might take the whole weekend. Don't ya think?

I am nothing but a fictional character. All I say should be treated as such- as it is only to make me look cool.

Re: Practice mash in the making. + Still questions

........My sugar wash is still fermenting...It's starting to confuse me. It's room temp this time though, so that is probably why. Smells very alcoholic.

For my pot still, I have my 3' liebig mocked w/o water in and outs. I got a nice looking union and a 45*. I'll have the 1 1/2" column, T and cap...or maybe just a 90* reducer by the weekend. I should be able to get to soldering it over the weekend as well! The only think I am worried about is that with the long liebig and the short stock pot, the output will need to hang off. The column will need to be probably two feet for it to be only a couple inches from table level. Im going to put the Union before the 45* so that I can adjust the angle of the condenser if for nothing else than to experiment. I'm also planning so on making a parrot.

Seems like I would be best suited with an electric heating element. What is suggested for a 20Q?

Pita.

Pics to come soon!!

For my pot still, I have my 3' liebig mocked w/o water in and outs. I got a nice looking union and a 45*. I'll have the 1 1/2" column, T and cap...or maybe just a 90* reducer by the weekend. I should be able to get to soldering it over the weekend as well! The only think I am worried about is that with the long liebig and the short stock pot, the output will need to hang off. The column will need to be probably two feet for it to be only a couple inches from table level. Im going to put the Union before the 45* so that I can adjust the angle of the condenser if for nothing else than to experiment. I'm also planning so on making a parrot.

Seems like I would be best suited with an electric heating element. What is suggested for a 20Q?

Pita.

Pics to come soon!!

I am nothing but a fictional character. All I say should be treated as such- as it is only to make me look cool.