Hey guys. I just put out an order for 3' of 1 1/2" copper for my column. I visited a couple stores to find reducing tees for that size, but the only one I could find was all 1 1/2" openings. Could I buy some reducers an grind off the larger part on them and solder em all together and be dandy? On the parent site, Bujapat's keg pot still looks like that was done- If I am not mistaken. The only other way would be ordering online. I only have a week to buy and solder everything before my buddy with the torch is gone.

Also, if I am going to do it this way - other than a vice, what would be needed? I was thinking along the lines of a cutting wheel. The only problem with that is I only have a drill, circular saw, and a hacksaw. No dremel for me. Do they even make cutoff wheel attachments for drills?

Thanks so much for your help guys. I've been asking a lot of questions lately. Hopefully it is not too annoying, and instead, helpful to others new to the hobby, or people running into the same problem.

Pita

Best/cheapest way from 1 1/2"column to 1/2" arm?

Moderator: Site Moderator

Best/cheapest way from 1 1/2"column to 1/2" arm?

I am nothing but a fictional character. All I say should be treated as such- as it is only to make me look cool.

-

StabbyJoe

- Swill Maker

- Posts: 164

- Joined: Thu Jul 10, 2008 2:18 am

- Location: New Zealand! (It's all legal =D)

Re: Best/cheapest way from 1 1/2"column to 1/2" arm?

would your drill even be fast enough? most dremels are operated at 30,000-35,000rpm...

Re: Best/cheapest way from 1 1/2"column to 1/2" arm?

Hmmm...that's a good point! I could probably do with the circular saw, it's just mighty awkward to use on something that small. It's what I used to cut all of my pipe to size, so it should work.

Would using only the reducing part of the reducers and soldering them in place work and be sturdy enough?

The sizes aren't set in stone. Just thrown up for reference.

The still picture that I referenced in the last post is on the parent site under "pot still photos".

Would using only the reducing part of the reducers and soldering them in place work and be sturdy enough?

The sizes aren't set in stone. Just thrown up for reference.

The still picture that I referenced in the last post is on the parent site under "pot still photos".

I am nothing but a fictional character. All I say should be treated as such- as it is only to make me look cool.

Re: Best/cheapest way from 1 1/2"column to 1/2" arm?

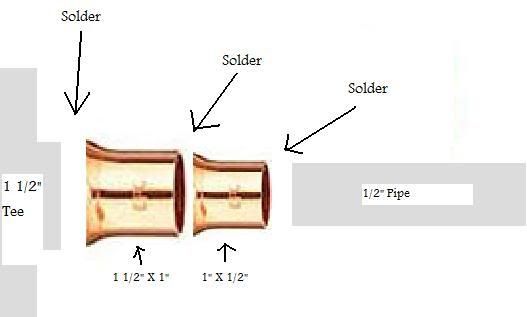

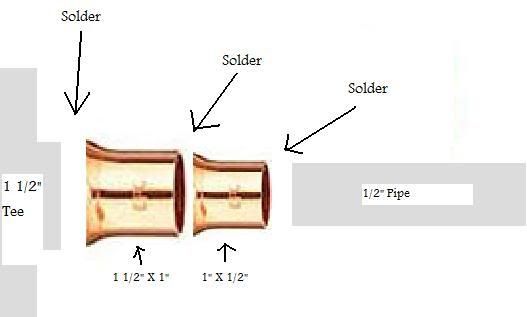

So, you've got a T 1 1/2x 1 1/2 x 1 1/2 and you want to connect to 1/2? I don't think you can do it in one reducer, but through use of several you could more easily do something like this. Cut a small piece of 1 1/2 pipe and connect to 1 1/2 T and a 1inch x 1 1/2 reducer, connect a small piece of 1in to the 1 in reducer and to a 1x1/2 in reducer etc. Maybe I'm not understanding what you're trying to do. These reducers are available at my local home centers. The reducers are pretty cheap. The 1 1/2 less so, but even so I did something similiar in 2 inch and the 2 in reducer was about $20. The rest are a couple dollars. It would be a lot easier.

Never refuse to do a kindness unless the act would work great injury to yourself, and never refuse to take a drink-- under any circumstances.

- Mark Twain's Notebook

- Mark Twain's Notebook

Re: Best/cheapest way from 1 1/2"column to 1/2" arm?

They do make two different types of reducers. One fits over both pipes. The other is the same size as the larger pipe and fits into the T. You would still need to do it in two steps, 1 1/2 to 1 and 1 to 1/2.

It is the very things that we think we know, that keep us from learning what we should know.

Valved Reflux, 3"x54" Bok 'mini', 2 liebig based pots and the 'Blockhead' 60K btu propane heat

Valved Reflux, 3"x54" Bok 'mini', 2 liebig based pots and the 'Blockhead' 60K btu propane heat

Re: Best/cheapest way from 1 1/2"column to 1/2" arm?

I understand how to step down to the desired diameter. However, it seems needlessly long, thus why I was looking into the practicality of shortening the reducers by chopping off the part that fits on the larger diameter of the two (like my picture). I would need to buy 1" for the step down otherwise. I did find a 1 1/2" x 1 1/2" x 1/2" online for $19US. That probably does not include shipment.

I am nothing but a fictional character. All I say should be treated as such- as it is only to make me look cool.

Re: Best/cheapest way from 1 1/2"column to 1/2" arm?

buy a 1.5" end cap and a .5" end cap, solder them together then drill a few holes. Something like this?

I know that someone used a similar idea as a column to lid attachment.

edit: removed pic because it deleted all the white space....

I know that someone used a similar idea as a column to lid attachment.

edit: removed pic because it deleted all the white space....

Last edited by mikeac on Tue Aug 05, 2008 10:10 am, edited 1 time in total.

Don't take life too seriously -- you'll never get out of it alive.

Re: Best/cheapest way from 1 1/2"column to 1/2" arm?

Hm. That's a creative idea. I found a suitable solution earlier today. I got a 1.5 90* elbow with only one coupling, then a 1.5X3/4 reducer, connnected to a 3/4 X 1/2 reducer. It looks alot better, and sticks out alot less, than the same idea but with a T, and less cuting. Pics up soon.mikeac wrote:buy a 1.5" end cap and a .5" end cap, solder them together then drill a few holes. Something like this?

1.5" cap

-------| .5" cap

||---

||---

-------|

I know that someone used a similar idea as a column to lid attachment.

I have a question about the length of pipe between couplings. How close can I put the couplings together and still be able to solder both joints? Can the be right up against eachother, or should more room be given?

Pita

I am nothing but a fictional character. All I say should be treated as such- as it is only to make me look cool.

Re: Best/cheapest way from 1 1/2"column to 1/2" arm?

Id have just a small gap ( 1/16-1/8 "), solder should just suck in there.