Just noodling around in the garage and I came up with this out of spare parts. What I have is an 1-1/4" main tube with a 1" bushing in the bottom of the Tee to accept an element. Everything is hand fit for now as I need to shop for some more parts; but I'll get there soon. I have abandoned the idea of 3" dairy tube since I have this and it won't require drilling, tapping and brazing stainless end caps like I was planning before.

Brutal, I think you might be correct about tube size being a non-issue for our purposes. Modern electric boilers get pretty small. Gas fired monotube boilers with a single coiled water tube also have extreme turbulence in the boiling. I'm not trying to be a power plant here and can tolerate the compromise of "wet" steam or reduced output efficiency.

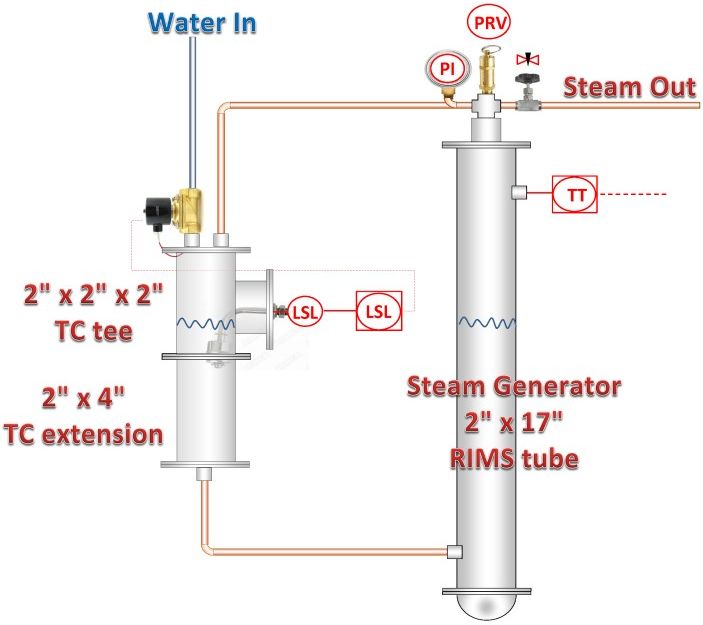

Now for sanity check; with a 5.5kW and a design point of 123oC/220 kPa, (250oF/15psig) it should consume 124 ml/min of 10oC feedwater or 134 ml/min of 60oC feedwater, (0.5kW more steam power if I use domestic hot vs cold water ). The water level in the 1-1/4" tube will drop at a rate of about 5"/minute which also seems pretty quick. I'll consider adding volume to the system and/or using an orifice plate on the fill to prevent short cycling the valve and also stabilizing the system.

Which brings me to the output side. I want to run it "valveless" on the steam discharge side with PID temperature controller and an orifice plate. A 0.125" orifice will induce upto 202 kPa (15 psig) of backpressure to the boiler given max power and will smooth the steam production. A globe valve just seems unnecessary and also a hazard if it were to be shut by accident. I already have the PID temp control available which can to throttle the power as I see fit through the orifice. The question becomes what temperature do I monitor for the control feedback? The boiler temp or product temp? I'll have to prove to myself that the orifice will limit the upper temp/pressure under full power to 250oF/15psig before I try anything else but it seems pretty slick to just set a product temp with steam. If the steam can also induce effective agitation... happy still'n ahead.

There will be 200 L/s of steam

passing through the orifice into 1/2" CSST at about 20 miles per hour. Hopefully fully condensing within my coil or mash...

I need to keep playing with an idea I have for the level control. My basic plan is to fabricate a hollow SS "pill" that can ride vertically inside a sight glass and float in water. Then a standard prox switch could be clamped to the exterior of the sight tube to trigger the fill.