Okay, You guys have heard that a thousand and one times. I'm going to go ahead and bore you with all me details and I welcome constructive criticism along the way.

Plan is for a ten gallon stainless stock pot with a 220 volt water heater element and home made controller. I am building a two foot tall column with 2" copper pipe. I intend to pack it with copper scrubbies and have wrapped the top with 1/4" water line to try to control the reflux, but I also intend to run it unpacked without the cooling to make some whiskeys. The condensor is a 1 1/2" copper with 3/4" fluted pipe inside, about 16" long. Cooling will be from a recirculating pond pump in a big cooler of chilled water, ice added to control the temps.

The aesthetics and build are just as important to me as producing fine products so each piece will be positioned and polished to please my eye. It also must be entirely functional so there's that too.

Here we go:

This is my dry fit. The pot of flux represents a brewers thermometer. Anyone see any big errors?

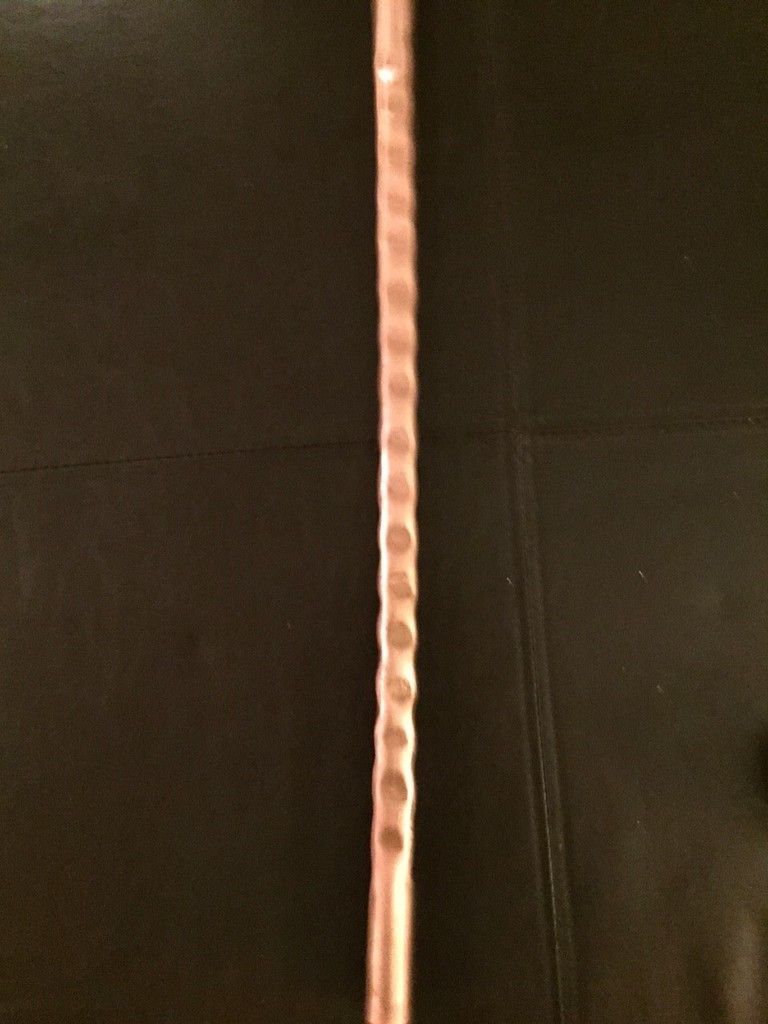

This is the inner 3/4" tube for the condenser. I fluted it to create some turbulence. It will be vertical.

I'm polishing each piece as I go. Looks like it's made of gold!

I'll be using a 2" NPT stainless nipple to mount the column to the pot lid. The pot is currently in the mail and ultimately I'd love to use a stainless mixing bowl as the lid and column base, but I have to find one that's just exactly right.

I'm an amateur welder and I've been contemplating trying to MIG the bung for the heater element and the nipple for the base but I haven't tried welding stainless before.

I'm ready to hear some opinions so, the range is open! Blast away!