Page 2 of 3

Posted: Fri Feb 08, 2008 1:10 pm

by CoopsOz

Mate, I don't know if I could trust it. They obviously have no concern for your health, I'd say they used leaded solder as well. Sorry to hear it's getting you down, I wish you had of found this site first. Personally, I think half the fun is building the still....You have all the basics to start again, but it's gonna take time.

Posted: Fri Feb 08, 2008 1:14 pm

by kingearwig

I think I can offer one piece of advice for you. It looks like you put this still away dirty. From my experience this is a big no no. I find that even stainless steel can rust in this situation. I don't think that you will be replacing the mounts for the heating elements and they appear to be some kind of coated steel(probably zinc). These will rust but you should be able to minimize it with proper care. you would want to wash it thoroughly before letting it dry thoroughly then when storing it it might be a good idea to put some veg oil on it. I think if it were my still I would spend a bunch of time cleaning the pieces that you have not replaced and make sure I take care them in a way that would prevent rust.... that is unless someone else here thinks that they are made of materials that are leaching bad things into you shine. Well then you got a lot of work to do.

Posted: Fri Feb 08, 2008 1:35 pm

by Jetzon

Coops, I cant agree with you more. Is there a way of telling what type of solder they used? And I wish I found this website sooner too! Think I'm gonna be making my own by the time I get this one back together.

Kingearwig. This Still is Brand New! All Ive done is run some water and vinager threw it trying to clean it out. That was suggested by everybody here. As for the water heating elements go, When they were new in the package they looked like metal. The brand is Camco USA. Just says standard replacement water heater element. Both were Brand new in package.

All Ive done is run water and vinager threw it, opened it up this morning to change water and was full of Rusty colored water. I'm soaking the elements right now in vinager and water. the water is just below the plastic where the wires hook up to. I know not to get the plastic casing or where the wires hook too wet...

Posted: Fri Feb 08, 2008 1:45 pm

by Dnderhead

You can git test kit forum hardware store four paint and such . as for

steel fitting in boiler their ok not the greatest but will do pretty sloppy

work id be ashamed to sell that

Posted: Fri Feb 08, 2008 7:35 pm

by HookLine

You are going to have to replace those heating element mounts, they are just too dangerous. Remove the mounts in there now, clean up the hole real well with a file and abrasive paper. Buy a couple of stainless half couplers with thread to suit the elements, and get them welded on by a pro stainless welder. It will cost a bit, but...

You can never post too many pictures of something like that, the more people see of it the better. The warning needs to get out about stilldrinkin. You are doing the distilling community a big favour by informing us of your bad experience and showing us the hard evidence.

I am having trouble believing just how bad a job that still is, but there it is, right there in front of my eyes.

Hey deep shit and duke, you still wanna defend these guys? I thought not.

Posted: Fri Feb 08, 2008 8:31 pm

by junkyard dawg

I get the feeling that these scumbags might also sell you a bottle of straight methanol and tell you it was top shelf likker...

I get the irony, but those pictures speak volumes. Those guys are crooks. I take back what I said about the cork, Thats the least of the problems. I don't think I would use that still. Not without a lot of work... a LOT of work...

thanks for posting those pics and telling your story.

Posted: Fri Feb 08, 2008 8:34 pm

by BW Redneck

Just seeing this sort of thing makes me angry. I believe that all frauds and counterfeiters should have to consume and or use the product they're trying to pass off as genuine.

Any legit still dealer would

at least make sure that their solder was food-safe and would use stainless bolts on their rigs. If they planned on getting repeat customers, they would hire a decent welder to do the fittings. I mean, I taught myself how to weld from a book and can do better than that. Bird shit beads and spatter all over the place. (Prolly didn't even use SS filler rod or wire.

) I feel nauseous when I see them.

Their design looks like it's about to fall over. I don't know, but wouldn't it be cheaper to have the thing laid out plumb, rather than at an angle?

Posted: Fri Feb 08, 2008 9:14 pm

by horsesareforwork

i did the mason jar thing on mine with some rum and orange peels set on top the copper packing. got about 150 proof of some fairly tasty stuff.

(i thought)

then i ran it on some carbon and stripped all the flavor out of it.

still good rum though.

the lead solder has been on my mind too, after seeing these guys in the sunlight. ordered a decent kit - should be here early next week. will post the results.

can't find a brass or ss flange for mine either. hadn't considered the heating element fittings, or what welding rod that might have been used. will have to look closer at mine. AS THE PLOT THICKENS

my heat control was wired in the box wrong. smoked it the 1st time i plugged it in. just been useing it direct though. no trouble with surges.

also replaced all the nuts and bolts that weren't ss.

fun little hobby, but as with most things in my life i didn't do the home work and am paying for it now.

Posted: Sat Feb 09, 2008 10:04 am

by ChillinDistilln

Once you get this cleaned up you will be happy with the performance. I have a similar tilt reflux still (minus the thumper) and I'm doing a run now and just measured in at 91%!!!

Posted: Sat Feb 09, 2008 10:31 am

by nutmg1

ChillinDistilln wrote:Once you get this cleaned up you will be happy with the performance. I have a similar tilt reflux still (minus the thumper) and I'm doing a run now and just measured in at 91%!!!

Hey Chillin,

Did you purchase your's from Stilldrinkin?

Posted: Sat Feb 09, 2008 11:10 am

by big worm

ok..this is real horse s**t were to start... first if your heater fittings are jb welded remove them and have a welder replace with s/s wells...high voltage and water do not mix..no way no how...ever! the dome is a mixing bowl sold at walmart if you need a new one. im gonna say this loud! IF YOU HAVE A STILLDRINKING STILL ARE YOU GONNA TRUST THESE JERKS TO HAVE USED NON-LEAD SOLDER?? just looking at what they have sold these guys i would never drink from one of their stills... start at the boiler fix the stuff and work up to the copper parts i would just take it appart with a torch clean the copper up, and re-solder with good silver solder...look don't risk your lives on a couple of cheap cheating bastards.

Posted: Sat Feb 09, 2008 11:17 am

by As-Ol-Joe

bigworm, tell us how you really feel. Don't hold back.

Posted: Sat Feb 09, 2008 11:23 am

by Dnderhead

seeing this and other prices somebody mite do good by offering "kits"

maybe a plumber who could get copper at discount

Posted: Sat Feb 09, 2008 11:42 am

by big worm

Dnderhead wrote:seeing this and other prices somebody mite do good by offering "kits"

maybe a plumber who could get copper at discount

exactly... how hard is it to be fair and decent? safty first and last...this stuff is not a toy you could grt hurt or hurt others..or worse

Posted: Sat Feb 09, 2008 11:53 am

by Dnderhead

Could be soled as "plumbing kit" assemble as you want "suggestions included"

Posted: Sat Feb 09, 2008 11:59 am

by big worm

ya know dnder this stuff on ebay and the web sites is not cheap folks are spending a chunk on "crap" wish they could read first then buy from a quality type person...seen good reveues right here on hd about reptuble dealers. also on not so good dealers. just kinda sucks to see good folks getting taken or hurt...or both

Posted: Sat Feb 09, 2008 12:19 pm

by nutmg1

Just curious.

What's the difference in cost between silver solder and regular (Lead).

Posted: Sat Feb 09, 2008 12:24 pm

by ChillinDistilln

nutmg1 wrote:ChillinDistilln wrote:Once you get this cleaned up you will be happy with the performance. I have a similar tilt reflux still (minus the thumper) and I'm doing a run now and just measured in at 91%!!!

Hey Chillin,

Did you purchase your's from Stilldrinkin?

No, I bought on ebay one made by these guys:

http://www.bluegrassmoonshinestills.com/" onclick="window.open(this.href);return false;" rel="nofollow

Posted: Sat Feb 09, 2008 12:27 pm

by big worm

nutmg1 wrote:Just curious.

What's the difference in cost between silver solder and regular (Lead).

i use hard sticks of silv-safe 15 "i think thats the name" $10.45 us per pound. but it takes real heat to use, not a propane torch. im sure they have "soft" type but i use ox/acc.

Posted: Sat Feb 09, 2008 1:08 pm

by As-Ol-Joe

nutmg1, they make lead free solder for drinking water use. It is in you home improvement store for about $5.00 a roll

Posted: Sat Feb 09, 2008 1:08 pm

by BW Redneck

Most soft solder doesn't even have lead in it anymore. Many "plumbing solders" are 95% tin, 5% copper. A few electronics companies are voluntarily trying to phase out the use of leaded, too. The only reason I'd even expect leaded to be used is because it's old and they're trying to get rid of it.

Posted: Sat Feb 09, 2008 1:27 pm

by nutmg1

Right on,

So its not like they were saving money if they used solder with lead in it. Makes it even worse. I suppose we sould wait and see how the tests come out.

I wish the dam thing was in my livingroom I'd go get a test kit right now and find out.

Posted: Sat Feb 09, 2008 2:10 pm

by CoopsOz

Apparently those test kits aren't all that accurate....not from personal experience, just reading on the net.

Posted: Sat Feb 09, 2008 2:11 pm

by rad14701

big worm wrote:ok..this is real horse s**t were to start... first if your heater fittings are jb welded remove them and have a welder replace with s/s wells...

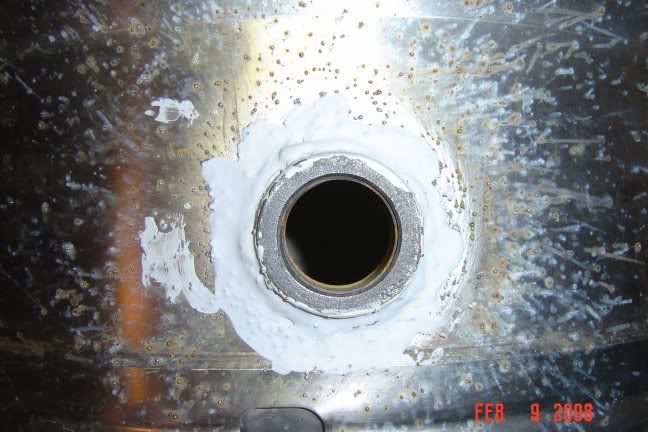

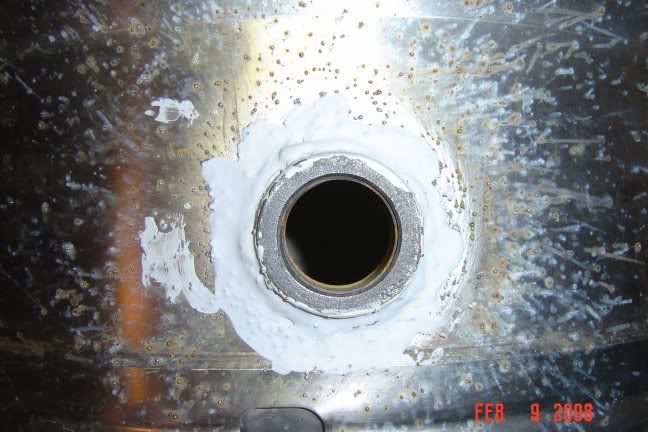

Taking another look at those fittings it actually looks like they used JB-Weld, or whatever they smeared on there, to hide shoddy welding... It does appear as though there is a weld bead under there, but based on the amount of spatter on the stainless, whoever did the welding needs more practice in welding dissimilar metals...

I am amazed that someone could continue selling inferior product, whether they sell direct, on eBay, or through any distribution channel for that matter...

Posted: Sat Feb 09, 2008 2:30 pm

by big worm

rad14701 wrote:big worm wrote:ok..this is real horse s**t were to start... first if your heater fittings are jb welded remove them and have a welder replace with s/s wells...

Taking another look at those fittings it actually looks like they used JB-Weld, or whatever they smeared on there, to hide shoddy welding... It does appear as though there is a weld bead under there, but based on the amount of spatter on the stainless, whoever did the welding needs more practice in welding dissimilar metals...

I am amazed that someone could continue selling inferior product, whether they sell direct, on eBay, or through any distribution channel for that matter...

they had to have tryed to braze it..my guess jb weld to just to make sure of no leaks...good ol quality control it does look like a shotgun blast from the pits...i'd be pissed if i was the owner. i love my propane burner

Posted: Sat Feb 09, 2008 2:36 pm

by big worm

some one help me out here

what is the angled slanted crooked deal with all these off set still columns??? surly they are not better than straight tall collums..are they ?? do they just catch the eye or is this done for a reson. i guess it would be good if you had a low celing.

bw

Posted: Sat Feb 09, 2008 6:18 pm

by Usge

The most common issue with those home lead test kits is false negatives (by far) and there are ways to test for that as well. The kit comes with a test strip (if you get a negative) which will induce a postive to make sure that the test swab is working. It is possible for a false positive, but it's pretty rare.

I recently tested my copper alembic and found postives for lead on the soldered joints. I've been corresponding with the manf about my findings and I'm not real happy about the results so far. I asked them if they had independently tested their solder source. And they said no...but were given assurances as to content by the manf. They are testing it now (supposedly). The one theory they came up with was, that in the particular test kit I used (which was the top rated for home kits), there is one caveat about testing lead free solder that contains a high level of "tin", it can cause the indicator to go instantly dark purple. This is not a false positive—which would turn the indicator pink to red. But, a false reading. They also suggested there could possibly be a little lead in it,but that whatever there was would be well within the EU standards for lead free. (wonderful)

I tested each joint several times. And the swab turned a lighter color before turning darker. I then tested a known different leadfree solder I had , including tin based, and I could not induce the same result. Then I swabbed the test strip and it turned pink/red...(the same color as the previous test). I reported those findings to them and never heard anything back. Not sure what to make of it...but given all that..I put away the copper alembic and have just been using my 4L ES.

Posted: Sat Feb 09, 2008 6:45 pm

by ChillinDistilln

big worm wrote:some one help me out here

what is the angled slanted crooked deal with all these off set still columns??? surly they are not better than straight tall collums..are they ?? do they just catch the eye or is this done for a reason. i guess it would be good if you had a low ceiling.

bw

I don't know much about the theory, but it would seem to me that they make a good hybrid still. I have mine packed with copper for the only straight run there is which is about 8 inches. Once the vapors get beyond the packing they have to rise in the tilt against the pipe and probably get some additional reflux.

I did an UJSM run today that lasted 10 hours and the middle ran at 90-91% which I consider pretty good. Since there is no cooling or control at the top, the heat at the bottom is the only control and I'm getting much better at it.

I'm enjoying a few shots right now and I'm pleased!

Posted: Sat Feb 09, 2008 6:53 pm

by Jetzon

I think I'm pretty much gonna have to Scrap this whole thing.

***I do have One more question about this. The head, Where your "Fuel" comes out of. Its a 2" piece of copper with a 1/2" piece of copper running threw it. Theres one 1/2" water line going in and one 1/2" water line going out. OK the question is. Doesn't that water line need to coil from the water in to the water out? Everything Ive seen here has a "COIL" copper line running threw it. All this one does is run the water into the head then has to Fill the whole 2" copper head up and then drain out the other end? theres no coil of copper in there. Just fills the head up with water and drains out the other end. I'll explain better in the pictures I hope. I also took a few more pictures of the keg showing there Wonderful JB weld job and how the water elements are Nice and rusty after I cleaned and dried them the best I could Also the Copper mesh they sent, I don't think thats the right stuff. its changing color compared to the mesh I bought from Brewhaus. This is the Same mesh that was in the Mason jar and the Same mesh I had in the column.

First picture is the Head and this is my Question fellers. The head is made from a 2" piece of copper. Inside theres a 1/2" line that the fuel comes out of. Also theres the coolant water lines. one in and one out. The water line goes into the head and HAS to fill the whole 2" head up then drains out the other 1/2 copper line? Thats not right? Or is that OK? I thought the 1/2 water line in should coil up to to the 1/2 water line out? Am I right?

The copper mesh on the left is from Stilldrinkn and was in the mason jar. The copper mesh on the right was in the column, Both were inside when I ran it out to clean. Both got just as hot. Look at the color difference. Its like Night and Day if you cant tell by pictures.

Heres some more pictures of the water heater connections, JB weld and how rusty this thing is.

I certainly do hope if not for anything else these pictures show people here what Stilldrinkn Crooks sell and Please do A LOT more homework before jumping into this hobby! As I seen here Many times and I cant agree more with. Safety First!

Please Remember. All this Rust is from ONE run on this still! Just water and vinager to clean it out thats it!

To all the Mods here. Please feel free to use Any of these pictures as you see fit. Like what Not to Buy and definitely not from them A-Holes.

Posted: Sat Feb 09, 2008 7:07 pm

by ChillinDistilln

The condenser design is just fine. You might be confusing the top of a reflux still with a condenser.

There is no need to scrap this still. Provided the solder doesn't contain lead (and it probably doesn't) just fix up the obvious flaws and start distilling (and Chillin).