High Level Overview of PID like Control

Moderator: Site Moderator

- shadylane

- Master of Distillation

- Posts: 11543

- Joined: Sat Oct 27, 2007 11:54 pm

- Location: Hiding In the Boiler room of the Insane asylum

Re: High Level Overview of PID like Control

Pot still or reflux

It doesn't make sense to me.

It doesn't make sense to me.

- NZChris

- Master of Distillation

- Posts: 13958

- Joined: Tue Apr 23, 2013 2:42 am

- Location: New Zealand

Re: High Level Overview of PID like Control

Your assumption is incorrect. For a stripping run, I run slow until the foreshot has been removed, then turn the Watts up. For a spirit run, I run slow until my nose tells me the heads are gone then turn the Watts up. Consequently, my early distillate is slow with less smearing right from the start, not just slowing as the temperature reaches a setpoint. Plus, I can run any type of product, including those that I've had no prior experience with, without having to find a 'correct' temperature to input into a PID.

-

StillerBoy

- Master of Distillation

- Posts: 3387

- Joined: Thu Dec 01, 2016 6:27 pm

- Location: Ontario

Re: High Level Overview of PID like Control

So can all of us do manually controlled runs, without taking notes, collecting jar after jar, checking the abv, smelling, tasting and spending time later doing cuts and cleaning up all those jars..

But what cayars is moving forward is the idea that with temp probes, and they don't have to be PID as I just use temp meter, is that when you are doing the same product over and over, it makes distillation very straight forward.. dial it in and rock and roll.. similar to the big guys..

In the last couple of years, the use of temp probes, has picked up some momentum.. personally I don't say much on there usage for the simple fact that it's an individual choice, and member don't like being told off by some that they are useless.. but I have been using temp probes for over 7 yrs now, and I wouldn't look back..

But.. Some like it slow.. Others like it fast.. and that's what makes the world move.. each to their own taste..

Mars

Last edited by StillerBoy on Fri Feb 14, 2020 5:23 pm, edited 1 time in total.

" I know quite certainly that I myself have no special talent. Curiosity, Obsession and dogged endurance, combined with self-criticism, have brought me to my knowledge and understanding "

– Albert Einstein

– Albert Einstein

- HDNB

- Site Mod

- Posts: 7427

- Joined: Mon Feb 17, 2014 10:04 am

- Location: the f-f-fu frozen north

Re: High Level Overview of PID like Control

No. it doesn't make sense to me. I fall into the KISS category of any "job".

From all of the argument i see here on this subject, you answered it yourself, right there. It seems that even you agree there is a better solution, but for the bored hobbiest this could be a nice distraction...not a better deal... just something to play with and get a bunch of (somewhat useless) data.

If i want to pound in a nail, i'm still going to go looking for a hammer.

like that guy sez...just my opinion, i may be wrong.

I finally quit drinking for good.

now i drink for evil.

now i drink for evil.

- HDNB

- Site Mod

- Posts: 7427

- Joined: Mon Feb 17, 2014 10:04 am

- Location: the f-f-fu frozen north

Re: High Level Overview of PID like Control

i'd like to hear Odin's opinion on the type of controller to use...this is basically his claim to fame "the same product over and over, it makes distillation very straight forward.. dial it in and rock and roll.. similar to the big guys.."StillerBoy wrote: ↑Fri Feb 14, 2020 5:05 pm the same product over and over, it makes distillation very straight forward.. dial it in and rock and roll.. similar to the big guys..

he uses all the programming and auto valves, sensors, temps and timing to make reproducible results. when you make and sell as many stills as him, you need some compelling reasons to use what you use. or more specifically people keep buying stills from him, they must have some compelling reasons themselves.

I finally quit drinking for good.

now i drink for evil.

now i drink for evil.

- NZChris

- Master of Distillation

- Posts: 13958

- Joined: Tue Apr 23, 2013 2:42 am

- Location: New Zealand

Re: High Level Overview of PID like Control

I've been doing that for years, but only with repeat products. I have one of the more automated pot stills around here to do it with, but I haven't taught it how to swap receivers yetStillerBoy wrote: ↑Fri Feb 14, 2020 5:05 pm what cayars is moving forward is the idea that with temp probes, and they don't have to be PID as I just use temp meter, is that when you are doing the same product over and over, it makes distillation very straight forward.. dial it in and rock and roll.. similar to the big guys..

-

StillerBoy

- Master of Distillation

- Posts: 3387

- Joined: Thu Dec 01, 2016 6:27 pm

- Location: Ontario

Re: High Level Overview of PID like Control

It's very simple.. he figured out what this thread is about many years back.. and didn't try to get anyone opinion on it.. he just went ahead and did his thing..

Yeah.. he needs to have all those extra, so that the people who purchase those still can relate to numbers, instead of learning what distillation is about..

I don't need Odin's equipment to run a still by numbers.. I've learned to read and understand what he has stated in many of his post here.. and I have taken the time to set up somewhat to his concept, without all the extra..

Mars

" I know quite certainly that I myself have no special talent. Curiosity, Obsession and dogged endurance, combined with self-criticism, have brought me to my knowledge and understanding "

– Albert Einstein

– Albert Einstein

-

StillerBoy

- Master of Distillation

- Posts: 3387

- Joined: Thu Dec 01, 2016 6:27 pm

- Location: Ontario

Re: High Level Overview of PID like Control

And neither have I.. lol

Mars

" I know quite certainly that I myself have no special talent. Curiosity, Obsession and dogged endurance, combined with self-criticism, have brought me to my knowledge and understanding "

– Albert Einstein

– Albert Einstein

- shadylane

- Master of Distillation

- Posts: 11543

- Joined: Sat Oct 27, 2007 11:54 pm

- Location: Hiding In the Boiler room of the Insane asylum

Re: High Level Overview of PID like Control

I have

90% of the time it worked

Unfortunately 10% of the time the turn table used would start going in the wrong direction

90% of the time it worked

Unfortunately 10% of the time the turn table used would start going in the wrong direction

-

StillerBoy

- Master of Distillation

- Posts: 3387

- Joined: Thu Dec 01, 2016 6:27 pm

- Location: Ontario

Re: High Level Overview of PID like Control

LOL.. You'll need to tweak the PID, or teach it to not have a drink when it at work..

Mars

" I know quite certainly that I myself have no special talent. Curiosity, Obsession and dogged endurance, combined with self-criticism, have brought me to my knowledge and understanding "

– Albert Einstein

– Albert Einstein

- shadylane

- Master of Distillation

- Posts: 11543

- Joined: Sat Oct 27, 2007 11:54 pm

- Location: Hiding In the Boiler room of the Insane asylum

Re: High Level Overview of PID like Control

"High Level Overview of PID like Control"

As normal, I'm confused

What exactly is a "PID like Control"

And what is needed to make a controller that act's like a PID

As normal, I'm confused

What exactly is a "PID like Control"

And what is needed to make a controller that act's like a PID

- HDNB

- Site Mod

- Posts: 7427

- Joined: Mon Feb 17, 2014 10:04 am

- Location: the f-f-fu frozen north

Re: High Level Overview of PID like Control

is thAT what he uses behind the computer, a PID controller? or is he controlling energy with SSR?StillerBoy wrote: ↑Fri Feb 14, 2020 5:34 pmIt's very simple.. he figured out what this thread is about many years back.. and didn't try to get anyone opinion on it.. he just went ahead and did his thing..

Yeah.. he needs to have all those extra, so that the people who purchase those still can relate to numbers, instead of learning what distillation is about..

I don't need Odin's equipment to run a still by numbers.. I've learned to read and understand what he has stated in many of his post here.. and I have taken the time to set up somewhat to his concept, without all the extra..

Mars

I finally quit drinking for good.

now i drink for evil.

now i drink for evil.

- Saltbush Bill

- Global moderator

- Posts: 10597

- Joined: Thu Mar 17, 2011 2:13 am

- Location: Northern NSW Australia

Re: High Level Overview of PID like Control

Exactly what Ive been wondering Shady.

This whole thing was about PID controlled boiler temps I thought.

is it it about PID's or" PID Like" things that could be used for the same purpose?....have the goal posts been shifted already?.

Lets get that cleared up to begin with.

- NZChris

- Master of Distillation

- Posts: 13958

- Joined: Tue Apr 23, 2013 2:42 am

- Location: New Zealand

Re: High Level Overview of PID like Control

You can have analogue proportional voltage control instead of using a cheap PID that trashes your elements with constant on/off cycles.Saltbush Bill wrote: ↑Fri Feb 14, 2020 6:37 pmExactly what Ive been wondering Shady.

This whole thing was about PID controlled boiler temps I thought.

is it it about PID's or" PID Like" things that could be used for the same purpose?....have the goal posts been shifted already?.

Lets get that cleared up to begin with.

-

cayars

- Distiller

- Posts: 1687

- Joined: Fri Aug 23, 2019 8:08 am

Re: High Level Overview of PID like Control

This is no argument, this is about how many people run stills using PID like controls, NOT if they should or not or if others think it's too complicated or if it's for newbs or people starting out.HDNB wrote: ↑Fri Feb 14, 2020 5:12 pmNo. it doesn't make sense to me. I fall into the KISS category of any "job".

From all of the argument i see here on this subject, you answered it yourself, right there. It seems that even you agree there is a better solution, but for the bored hobbiest this could be a nice distraction...not a better deal... just something to play with and get a bunch of (somewhat useless) data.

If i want to pound in a nail, i'm still going to go looking for a hammer.

like that guy sez...just my opinion, i may be wrong.

You obviously favor simplicity over better results based on the KISS comment. Nothing wrong with that if it's your thing. I personally want to make the best product I can using any tool I find easy & cheap to use that matches the knowledge I already have from controlling distillation in the fuel industry.

I think a good analogy in the auto world would be a manual vs automatic transmission in your car. Both work, but one clearly gives you more control over what the car is doing vs the other being more simpler (KISS) and generally easier to use. In this day and age I'd recommend the automatic transmission to someone who is new to driving as it's one less thing to worry about and they can focus on other things. BUT if the person has experience with manual transmissions in other vehicles like a motor cycle, dirt bike, quad or 3 wheeler it might be second nature to them driving a car as well and I'd not steer them away from having more control even as a newb to auto driving. For them it's not just something to play with but a tool that gives them more control over how the auto drives.

I too might go for the hammer but depending on the job could very well use my nail gun. I just pick the best tool I happen to have on hand to fit the job at hand.

Programmer specializing in process control for ExxonMobil (ethanol refinery control), WT, Omron, Bosch, Honeywell & Boeing.

More than a decade working for NASA & FAA Tech with computer code used on Space Shuttles and some airline flight recorders.

More than a decade working for NASA & FAA Tech with computer code used on Space Shuttles and some airline flight recorders.

-

charcoal

- Swill Maker

- Posts: 262

- Joined: Sat Nov 02, 2019 3:28 pm

Re: High Level Overview of PID like Control

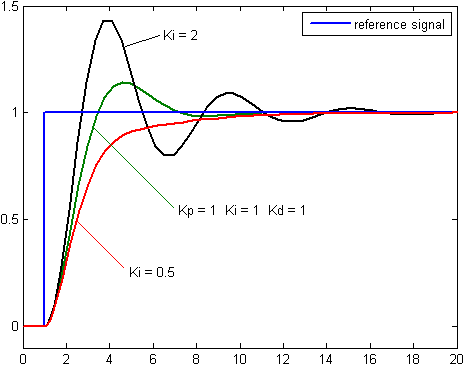

PID is a specialised type of switch that will try to reach a temperature by say, starting a heater and switching it off when it reaches the temp. When it does it, the first few times it will overshoot it and then will keep itself off so the temp comes down. It may even start a cooling process.

For example, a human operator will heat something to say, 66 C. He will switch it off when it reaches 65 but then he will find that it has overshot and reached 70 degrees C. He will wait for this temp to drop below 66 and then start the heating again after reducing the power flowing in the heating element or reduce the duty cycle, so it will again rise but he will not be overshooting this time by 4 degrees. This time, by the time he switches it on again, it would have fallen to 63 and after heating it again the overshooting will take the temp to say 68 only. The operator will let it cool again and increase the heat much slowly so that the air cooling losses/ liquid leakage etc are compensated by a slower heating capacity and remains as close as 66.

A PID will try to learn and copy the above operator and will show results like

Heat can be reduced in multiple ways

You can use a rheostat to reduce current in the heater (This has discrete power settings but wastes power)

You can use a variable step down transformer for AC Heaters (This has discrete power settings)

You can take out some elements from the heating system (This has discrete power settings)

Or you can

Chop the current passing in the heaters by switching the element on and off. This is the point which most people don't like but

EVERY AC HEATER IN UK/AUS/NZ/INDIA IS SWITCHED OFF 100 TIMES A SECOND

EVERY AC HEATER IN USA/JAPAN IS SWITCHED OFF 120 TIMES A SECOND.

We can switch it off even more and even chop the waveform and reduce heating.

This is done by

Thermostat (Crude but simple). It is a rough control but switching on and off can take like 15 seconds or so. This the clicking control in the electric hot plates

SCR based (stepless settings). This a faster component and can chop even a single waveform.

A Dimmer chopping a single wave cycle

A Dimmer switching off for certain cycles

-

cayars

- Distiller

- Posts: 1687

- Joined: Fri Aug 23, 2019 8:08 am

Re: High Level Overview of PID like Control

This and the turn table comments were funny.

That or if automating use an electronic 3 or 4 way valve and not switch containers but to what collection container the distillate is flowing to.

I used the wording "PID like Control" on purpose. I wanted to keep this more about the technique then specific hardware. It could be an actual PID, could be a Pi, Arduino, computer or person mimicking this functionality by hand holding at temp.

A PID, Pi, Aurduino or computer can all monitor a probe, make a decision based on an algorithm and turn on/off a relay all achieving the same result. How it's done is less important then what is done, thus "PID like".

Check with your manufacture and I bet they will tell you this doesn't matter much. They are designed to work this way. This is the way the elements work on a stove and in a water heater. They are more likely to fail when left on for long periods of time without cycling and of course when dry fired or when fluid around the element doesn't move and it overheats and burns out. Allowing your element to run dirty is the fastest way to kill it next to dry firing. Keep the element clean and it should last a long time.

Cycling power on/off is a much better use of electricity and cheaper than bleeding off power to a heat sink as that is wasted power. That saving in wasted power depending on your wattage and time of use could buy you a new element pretty quickly. That is why stoves and electric heaters use on/off duty cycles vs bleeding energy to a heat sink.

Programmer specializing in process control for ExxonMobil (ethanol refinery control), WT, Omron, Bosch, Honeywell & Boeing.

More than a decade working for NASA & FAA Tech with computer code used on Space Shuttles and some airline flight recorders.

More than a decade working for NASA & FAA Tech with computer code used on Space Shuttles and some airline flight recorders.

-

cayars

- Distiller

- Posts: 1687

- Joined: Fri Aug 23, 2019 8:08 am

Re: High Level Overview of PID like Control

Charcoal, what you describe above is a typical "auto tune" where you let the PID learn how to make adjustments on it's own. That works well for fermentation or beer brewing but "auto tune" can be the devil used in distillation and is why many people fail using a PID on a still. Turn off the auto learning and program it specifically how to work which requires learning I an D functionality. This is needed because on a still the temp changes and you need to be able to "drive" it to get flow but not too much flow.  So you need to take over or constrain the "rate of change" that is allowed to happen.

So you need to take over or constrain the "rate of change" that is allowed to happen.

For example you can't allow it to run 100% with a big element at the start of hearts take off as you could end up with a big fat thick stream when you want to constrain it to a thin stream or fast drip to keep from smearing. The "auto tune" programming might be just fine for heads and tails collection however. For tails you are just collecting what's left so no big deal. For heads the temp range of collecting is so small that this may not matter much as well but in the hearts section which has a large temp range it does matter. You of course can sort of work around this in hearts using auto tune to get started by having several different target temp points so the PID doesn't overdrive things but that gets old quick. You'll understand this shortly.

That is probably the biggest hurdle to using a PID (proper programming). Unfortunately every PID is different so you can't share logic/programming between brands and even between different controllers from the same manufacture. The person using the PID more or less has to dive in to learn how that UNIT works with THEIR STILL and adjust it accordingly.

That leads to another hurdle which is the instructions on how to use the device. If you order a Chinese unit it might be a perfectly fine device but come with "Chinglish" instructions. <-- Chinese instructions poorly translated to English (or your language if not English) that make understanding down right hard. For that reason it's often best to spend 2x or 3x to buy American (or from your own country) to get a product with clear instructions written well in your language so that you can actually learn how to use the device properly. Once you understand how PIDs work then where you buy from is far less important as most work similar even if differently.

PS I'm trying to keep this thread "fair and balanced" with information pro/con to PIDs as they are not a "drop in" solution you can flip a switch and use without prior knowledge, thus usually unfit for novices or those looking for KISS mechanisms. It's a tool for those wanting to up their game.

For example you can't allow it to run 100% with a big element at the start of hearts take off as you could end up with a big fat thick stream when you want to constrain it to a thin stream or fast drip to keep from smearing. The "auto tune" programming might be just fine for heads and tails collection however. For tails you are just collecting what's left so no big deal. For heads the temp range of collecting is so small that this may not matter much as well but in the hearts section which has a large temp range it does matter. You of course can sort of work around this in hearts using auto tune to get started by having several different target temp points so the PID doesn't overdrive things but that gets old quick. You'll understand this shortly.

That is probably the biggest hurdle to using a PID (proper programming). Unfortunately every PID is different so you can't share logic/programming between brands and even between different controllers from the same manufacture. The person using the PID more or less has to dive in to learn how that UNIT works with THEIR STILL and adjust it accordingly.

That leads to another hurdle which is the instructions on how to use the device. If you order a Chinese unit it might be a perfectly fine device but come with "Chinglish" instructions. <-- Chinese instructions poorly translated to English (or your language if not English) that make understanding down right hard. For that reason it's often best to spend 2x or 3x to buy American (or from your own country) to get a product with clear instructions written well in your language so that you can actually learn how to use the device properly. Once you understand how PIDs work then where you buy from is far less important as most work similar even if differently.

PS I'm trying to keep this thread "fair and balanced" with information pro/con to PIDs as they are not a "drop in" solution you can flip a switch and use without prior knowledge, thus usually unfit for novices or those looking for KISS mechanisms. It's a tool for those wanting to up their game.

Programmer specializing in process control for ExxonMobil (ethanol refinery control), WT, Omron, Bosch, Honeywell & Boeing.

More than a decade working for NASA & FAA Tech with computer code used on Space Shuttles and some airline flight recorders.

More than a decade working for NASA & FAA Tech with computer code used on Space Shuttles and some airline flight recorders.

-

charcoal

- Swill Maker

- Posts: 262

- Joined: Sat Nov 02, 2019 3:28 pm

Re: High Level Overview of PID like Control

Actually this is my first time using a PID and I need to learn it too.

I normally let it run full when stripping. I want to control this still when in relfux mode.

I want to run it in a way that I am not running lots of cooling and fighting it with my heater. I hope to run it on say 500W heating.

InkBird is certified in Australia and is quite a popular brand. Actually it is quite famous in USA as well. Kegland has not bothered to get Australian Certification for their products. They just sell a programmable Thermostat and one power controller.

Anyway, I would know more tomorrow.

I normally let it run full when stripping. I want to control this still when in relfux mode.

I want to run it in a way that I am not running lots of cooling and fighting it with my heater. I hope to run it on say 500W heating.

InkBird is certified in Australia and is quite a popular brand. Actually it is quite famous in USA as well. Kegland has not bothered to get Australian Certification for their products. They just sell a programmable Thermostat and one power controller.

Anyway, I would know more tomorrow.

-

cayars

- Distiller

- Posts: 1687

- Joined: Fri Aug 23, 2019 8:08 am

Re: High Level Overview of PID like Control

I think you just mentioned a few posts back that this was normal for you when running under reflux.

So you do experience this in reflux but don't understand why this is also beneficial with a pot still correct?

I'm not picking on your post, but think this is common to a lot of people. If the above is correct I may be able to explain it so it can make sense.

No, I was correct in saying you fall into 4A as mentioned in the op post based on your other posts. The op post is not about strip runs but spirit runs. You rely on your nose to tell you when heads are done then turn up the watts. This is not what a 4B person would do. A 4B person already knows where heads end/hearts start and has programmed that into the run. Each and every run there after can be used to fine tune those setting in 1/10 or 1/100 degree increments. So each and every run can be used to improve the process being used.NZChris wrote: ↑Fri Feb 14, 2020 4:40 pmYour assumption is incorrect. For a stripping run, I run slow until the foreshot has been removed, then turn the Watts up. For a spirit run, I run slow until my nose tells me the heads are gone then turn the Watts up. Consequently, my early distillate is slow with less smearing right from the start, not just slowing as the temperature reaches a setpoint. Plus, I can run any type of product, including those that I've had no prior experience with, without having to find a 'correct' temperature to input into a PID.

You and I are not really that far out in overall style if you can believe that. You do it every run to make "on the fly cuts" vs me and Mars who use past experience as well (at times) on the fly taste/smell to make adjustments.

The physics of distilling does not change regardless of starting ABV or if you are running Rum, Whiskey, Brandy or Vodka. Where you want to start collection your "middle cuts" is different of course depending on spirit. Brandy will likely be more heads centric where the flavor is compared to whiskey which might want late heads AND early tails. Vodka will generally want to avoid both heads and tails for a "neutral" cut, etc.

What Mars and I are doing is using physics and past logging/runs to influence our next runs. We use the abundance of past data to make future decisions. This allows us to do runs when sick, with a stuffy nose, after eating super spicy food, etc. We don't worry about how we feel that day or what we recently ingested, smoked or drank that could influence our pallet or ability to taste and smell. We essentially use the "average" of past runs vs just the present run. But we do it in a smart way to collect BIG for heads, hearts & tails but also can collect transitions jars in small amounts for later evaluation and small variations batch to batch or spirit to spirit. Super simple process for us.

Knowing the way distillation works and how heads, hearts and tails flow at different temps we can also do a brand new type of spirit and be close to on the money as well using something similar as a reference. We may get more or less methanol or acetone but they still come off the still at specific temps so we don't get tripped up by trying to follow volume. We essentially follow temp and proof (derived) to make cuts while controlling flow rate to avoid smearing and allow the higher order alcohols to flow when they will. We use this this to our advantage.

Programmer specializing in process control for ExxonMobil (ethanol refinery control), WT, Omron, Bosch, Honeywell & Boeing.

More than a decade working for NASA & FAA Tech with computer code used on Space Shuttles and some airline flight recorders.

More than a decade working for NASA & FAA Tech with computer code used on Space Shuttles and some airline flight recorders.

- Tater

- Admin

- Posts: 9836

- Joined: Mon Oct 25, 2004 9:19 am

- Location: occupied south

Re: High Level Overview of PID like Control

Cook stoves do use off on cycles to heat with Infinite Switches .The oven and water heaters use on off tstats that stay on full power till temp is reached.Infinite Switches have caused some a problem with maintaining even heat in small stills .

I use a pot still.Sometimes with a thumper

- ShineonCrazyDiamond

- Global moderator

- Posts: 3468

- Joined: Thu Feb 27, 2014 6:14 pm

- Location: Look Up

Re: High Level Overview of PID like Control

Listen, make your case for playing with your toy all you like. But don't be so conceded and ignorant that you interchange "complicated or advanced" for "better". You guys are here trying to emulate commercial operations as the standard, and I left those standards in my mirror years ago. I am in this hobby becuase I make far better liquor than they do. It's a matter of production process and economics that drives the need for them. They set numbers, and let the blender sort it out. I get to sort it out from first drop to last drop.

Besides, how boring it must be to have to run the same exact recipe over and over for the sake of repeatability and ability to use a commercial set up.

"Come on you stranger, you legend, you martyr, and shine!

You reached for the secret too soon, you cried for the moon.

Shine on you crazy diamond."

You reached for the secret too soon, you cried for the moon.

Shine on you crazy diamond."

- ShineonCrazyDiamond

- Global moderator

- Posts: 3468

- Joined: Thu Feb 27, 2014 6:14 pm

- Location: Look Up

Re: High Level Overview of PID like Control

I was trying to make sense of this in context, assuming you were referring to general PID operations. I feel obligated though, as a mod, to issue the following.

Anyone that suggest the use of using a PID as means to leave an automated still unintended, for any amount of time, will have the thread automatically locked, post removed, and membership revoked.

We must not forget that this is a hobbyist site, with the purpose of promoting safe distilling practice at home, with the intent to influence legal change by illustration of responsible practice.

"Come on you stranger, you legend, you martyr, and shine!

You reached for the secret too soon, you cried for the moon.

Shine on you crazy diamond."

You reached for the secret too soon, you cried for the moon.

Shine on you crazy diamond."

-

StillerBoy

- Master of Distillation

- Posts: 3387

- Joined: Thu Dec 01, 2016 6:27 pm

- Location: Ontario

Re: High Level Overview of PID like Control

Will maybe for some, but for myself personal, I like repeatability especially for making the base used in gin, pastis, and apple pie..ShineonCrazyDiamond wrote: ↑Sat Feb 15, 2020 5:43 am Besides, how boring it must be to have to run the same exact recipe over and over for the sake of repeatability and ability to use a commercial set up.

Once the base is produced, the making of those flavored product are not done in a commercial style, they are done on one batch at a time..

People are mixing and matching and are trying to make it fit.. most of the negative comments has been emotionally based, and there is no need for it..

Mars

" I know quite certainly that I myself have no special talent. Curiosity, Obsession and dogged endurance, combined with self-criticism, have brought me to my knowledge and understanding "

– Albert Einstein

– Albert Einstein

- ShineonCrazyDiamond

- Global moderator

- Posts: 3468

- Joined: Thu Feb 27, 2014 6:14 pm

- Location: Look Up

Re: High Level Overview of PID like Control

That comment was my personal opinion, and I stand by it. To each their own, though. Same reason I don't fill a 53 gallon barrel. I could definitly do it, especially with a friend, but in the end, do I really want that much of one thing?

I could understand the neutral a little, so good point. But for me, I would be inclined to try and make oat based nuetral, all grain neutral, shady neutral, all feints neutral, etc. I'd always be chasing creativity and experimentation, as to not get bored.

I could understand the neutral a little, so good point. But for me, I would be inclined to try and make oat based nuetral, all grain neutral, shady neutral, all feints neutral, etc. I'd always be chasing creativity and experimentation, as to not get bored.

"Come on you stranger, you legend, you martyr, and shine!

You reached for the secret too soon, you cried for the moon.

Shine on you crazy diamond."

You reached for the secret too soon, you cried for the moon.

Shine on you crazy diamond."

-

StillerBoy

- Master of Distillation

- Posts: 3387

- Joined: Thu Dec 01, 2016 6:27 pm

- Location: Ontario

Re: High Level Overview of PID like Control

Making neutral from all grain or sugar base is a fermentation process.. and yes I have done those recipes and i have a few I like..ShineonCrazyDiamond wrote: ↑Sat Feb 15, 2020 6:13 am But for me, I would be inclined to try and make oat based nuetral, all grain neutral, shady neutral, all feints neutral, etc. I'd always be chasing creativity and experimentation, as to not get bored.

But the distillation process become pretty much all the same after having done a few run on each different ones..

And the process or the different process available to make a finish product is what this thread is about.. one step in the advancement of the understand a different process..

Some enjoy whiskey's, others prefer gin's or some other product.. for me it's gin and pastis, and there are some many different flavors that can be made from those two.. plus the neutral is the base use for making my herbal tincture with..

Mars

" I know quite certainly that I myself have no special talent. Curiosity, Obsession and dogged endurance, combined with self-criticism, have brought me to my knowledge and understanding "

– Albert Einstein

– Albert Einstein

- Tater

- Admin

- Posts: 9836

- Joined: Mon Oct 25, 2004 9:19 am

- Location: occupied south

Re: High Level Overview of PID like Control

Lets get back to topic of controller .

I use a pot still.Sometimes with a thumper

- HDNB

- Site Mod

- Posts: 7427

- Joined: Mon Feb 17, 2014 10:04 am

- Location: the f-f-fu frozen north

Re: High Level Overview of PID like Control

your argument that you are not arguing is...an argument. i wasn't looking for a response, just stating an opinion- my conclusion drawn from your earlier argument.cayars wrote: ↑Fri Feb 14, 2020 9:58 pmThis is no argument, this is about how many people run stills using PID like controls, NOT if they should or not or if others think it's too complicated or if it's for newbs or people starting out.HDNB wrote: ↑Fri Feb 14, 2020 5:12 pmNo. it doesn't make sense to me. I fall into the KISS category of any "job".

From all of the argument i see here on this subject, you answered it yourself, right there. It seems that even you agree there is a better solution, but for the bored hobbiest this could be a nice distraction...not a better deal... just something to play with and get a bunch of (somewhat useless) data.

If i want to pound in a nail, i'm still going to go looking for a hammer.

like that guy sez...just my opinion, i may be wrong.

You obviously favor simplicity over better results based on the KISS comment. Nothing wrong with that if it's your thing. I personally want to make the best product I can using any tool I find easy & cheap to use that matches the knowledge I already have from controlling distillation in the fuel industry.

I think a good analogy in the auto world would be a manual vs automatic transmission in your car. Both work, but one clearly gives you more control over what the car is doing vs the other being more simpler (KISS) and generally easier to use. In this day and age I'd recommend the automatic transmission to someone who is new to driving as it's one less thing to worry about and they can focus on other things. BUT if the person has experience with manual transmissions in other vehicles like a motor cycle, dirt bike, quad or 3 wheeler it might be second nature to them driving a car as well and I'd not steer them away from having more control even as a newb to auto driving. For them it's not just something to play with but a tool that gives them more control over how the auto drives.

I too might go for the hammer but depending on the job could very well use my nail gun. I just pick the best tool I happen to have on hand to fit the job at hand.

i do favour simplicity; in fact i would argue your analogy in the auto world is a)unrelated and b) incorrect. if you want to relate it you could draw on the (dis)similarities of a CVT vs a hydraulic transmission perhaps and equate that to PID v SSR. relating a manual transmission to an automatic would be more akin to likening a wood fire to an electrically controlled rig. further, i would tell you that manual transmission offer less control than an infinite control of an automatic. or perhaps that is the argument, that the power on OR off nature of a manual (is PID) and therefore somehow an improvement over the smooth, infinite control of an automatic (being an SSR)

but then transmissions evolved from a manual to an automatic, didn't they?

as for the hammer, you take the ridiculous to the sublime. I LURV my pasload. it is the simplest way to insert a nail...but i don't see anyone arguing that they should try modifying the semi automatic (on/off) nature of the tool to a fully automatic version that spits out nails as long as the trigger is pulled.

We could open an arguement about the benefits of a fully auto nail gun, that you could "turn up" with a rheostat moving the fundamental nature from it's current on/off design to a an automatic smooth control of an SSR design...the opposite of the argument contained herein; it would none the less be as equally ill conceived and one could expect negative feedback to the idea from experienced pasload operators.

Edit: srry Tater, i typed this before you posted and i have not read all the way to the end of this thread yet. I'm usually a say my bit and leave it alone guy, but this arguing for the sake of arguing seems to be my thing today. we all seem to think we know what's best for the job. I'm not going to waste my time or money building a PID controller to run some experiments and post the results, so i'll shut up now...maybe those are the next steps, buck up with some part numbers, schematics, build threads photos and experiments, and cut the theory BS. lets see some practical application and the results

I finally quit drinking for good.

now i drink for evil.

now i drink for evil.

- Corsaire

- Distiller

- Posts: 1131

- Joined: Tue Jun 20, 2017 1:20 pm

- Location: Belgium

Re: High Level Overview of PID like Control

Thanks for the explanation.

I think I know what they do now, and it was enlightening to read how you do a spirit run.

I don't think pid is what I need. I'm a chaotic person, my recipes constantly change depending on mood and resources. I doubt I'll make the same recipe enough and take enough notes at this time in my life to get any benefit using this method.

To each their own. That's the beauty of this hobby. No one size fits all, make it fit your needs.

I think I know what they do now, and it was enlightening to read how you do a spirit run.

I don't think pid is what I need. I'm a chaotic person, my recipes constantly change depending on mood and resources. I doubt I'll make the same recipe enough and take enough notes at this time in my life to get any benefit using this method.

To each their own. That's the beauty of this hobby. No one size fits all, make it fit your needs.

- NZChris

- Master of Distillation

- Posts: 13958

- Joined: Tue Apr 23, 2013 2:42 am

- Location: New Zealand

Re: High Level Overview of PID like Control

You seem to like making assumptions about what other people do, but you're not very good at it. The only cuts 'on the fly' that happen in my shed are for base spirits for gin and the likes. For repeat flavored products, I use my past records to tell me when I should be running into small jars so that I can make the final choice of cut. Because I'm a home distiller and not pumping out large volumes of the same pap day after day, I often blend myself more than one style of cut out of one spirit run.

Read my lips.... "more than one style of cut out of one spirit run". I don't believe that there is a magic temperature that makes the finest possible outcome for a flavored spirit.