Page 29 of 63

Re: FLUTE TALK

Posted: Mon Feb 21, 2011 4:49 am

by olddog

Wow

96ABVThis will be the first Flute to achieve that on a single run, congratulations Wayne. I see it's working as designed

OD

Re: FLUTE TALK

Posted: Mon Feb 21, 2011 5:07 am

by LWTCS

Martinnis for everyone

Yes, been waiting to hear about the 10 plate run.

150 ml of tails,,,,,,,oh mammy that is squeezin it down pretty good.

And 2.2 @ 95,,,,,,,,again,,,that seems like some very good compression.............No stripping,,,,,30 liters in 3 hours with the goodly reflux period included!

How would you describe the size of your stream Wayne?

Re: FLUTE TALK

Posted: Mon Feb 21, 2011 1:06 pm

by DOLIKEADRINK

Howdy

The stream size was probably from a match stick to a pencil lead, Not quite the size of my pot still stream and maybe a bit under the size of when I run the 4 plater. I have done a few of batches of Hook Rum with the 4 plater and it smells amazing and I don't like Rum, But I recon I might just have a couple when it is aged this stuff just smells so Bloody clean. I haven't even tasted my UJSSM yet

I am trying to let it age nice and slowly no touching for 3 months min, Shit it's hard but when it smells so bloody good, Lucky I have a good supply of my Pot Still UJSSM

Cheers: Dolikeadrink

Re: FLUTE TALK

Posted: Mon Feb 21, 2011 2:58 pm

by likkerluvver

DOLIKEADRINK wrote:Howdy

..... I have done a few of batches of Hook Rum with the 4 plater and it smells amazing and I don't like Rum, But I recon I might just have a couple when it is aged this stuff just smells so Bloody clean. I haven't even tasted my UJSSM yet

I am trying to let it age nice and slowly no touching for 3 months min, Shit it's hard but when it smells so bloody good, Lucky I have a good supply of my Pot Still UJSSM

Cheers: Dolikeadrink

I somehow lost the first part of my earlier post,

so here are: My congrats on the 95+% on the Birdwatcher's in 10-plate mode. The rig sure is an impressive build, with lots of versatility.

I am wondering how the cleanest neutral (the 10-plate config. can produce) will compare with that of a Bok or a VM when shooting for azeotrope?

I look forward to hearing more about the flavour carry-over in 4-plate mode in due time - how it compares with your previous pot-stilled rum and UJSSM product.

All sounds good so far.

Re: FLUTE TALK

Posted: Mon Feb 21, 2011 3:03 pm

by Austin Nichols

I ran a BW wash a few days ago trying to make a neutral from 5 plates.

- IMG_0219.JPG (13.51 KiB) Viewed 2236 times

After airing for 48 hours it's pretty good.

Re: FLUTE TALK

Posted: Mon Feb 21, 2011 3:07 pm

by thepatchworkdoll

Hey Austin

Is that a 5 plate sieve still or bubble cap. That reading on the alcometer is sound.

Regards

Thepatchworkdoll

Re: FLUTE TALK

Posted: Mon Feb 21, 2011 3:34 pm

by DOLIKEADRINK

Austin Nichols wrote:I ran a BW wash a few days ago trying to make a neutral from 5 plates.

IMG_0219.JPG

After airing for 48 hours it's pretty good.

Hey Austin how did your neutral taste from 5 plates

That looks like 96% to me

What temp was the sprit

I got OLDDOG to put a temp port in my Parrot like the one you made, Great simple idea well done.

Cheers: Dolikeadrink

Re: FLUTE TALK

Posted: Mon Feb 21, 2011 3:57 pm

by likkerluvver

Hey guys,

It all looks pretty impressive. AND on just 5 plates AN. WOW

Keep us posted on the flavour carry-over (where you WANT it (heavier rums, whiskeys, etc.) as compared with straight pot-stillin' - when you have a chance.

Re: FLUTE TALK

Posted: Mon Feb 21, 2011 4:02 pm

by Austin Nichols

Distillate temp was 21.3c, I have to run my coolant inlet line through a bucket of iced water because my tank water is at 28c.

It tastes ok, not brilliant, but pretty good, I had to run pretty slow with lots of reflux to bump the ABV up tho.

Edit: to add, it's got 5 perforated plates.

Re: OLDDOG'S 10 PLATER

Posted: Wed Feb 23, 2011 2:26 am

by prdbrissy

DOLIKEADRINK wrote:

I dropped my temp gauge into my parrot that olddog made for me (one of his new design) it worked like a treat no surging at all, The temp was 24.7 dropped in my alcometer

95% straight away

Holey snapping duck shit batman far out

During the run I saw 96% it actually floated between 95% and 96% throughout the whole run.

DOLIKEADRINK was this in pot sit mode or was there some reflux going on?

Regards

Re: FLUTE TALK

Posted: Wed Feb 23, 2011 4:45 am

by LWTCS

@PB

Definitely not pot mode with all 10 plates in the line up.

And ikm pretty sure a bit of forced reflux is requisite to keep the perf plates loaded

Running with no reflux would prolly only get you into the early to mid 80s

Re: FLUTE TALK

Posted: Sun Feb 27, 2011 6:36 am

by valkyrie99

Asking for opinions about design. My column is 24 inches long and im using 4 plates. What im wondering is how much below the deflagmater should the top plate be? Would there be an advantage or disavantage to lowering them some or just putting it 4 or so inches and leaving the extra at the bottom in case i want to add another plate later.

Thanks for your thoughts on this. Valk

Re: FLUTE TALK

Posted: Sun Feb 27, 2011 5:16 pm

by olddog

valkyrie99 wrote:Asking for opinions about design. My column is 24 inches long and im using 4 plates. What im wondering is how much below the deflagmater should the top plate be?

4-5 inches, the same as the gap between your plates.

OD

Re: FLUTE TALK

Posted: Sun Feb 27, 2011 11:02 pm

by prdbrissy

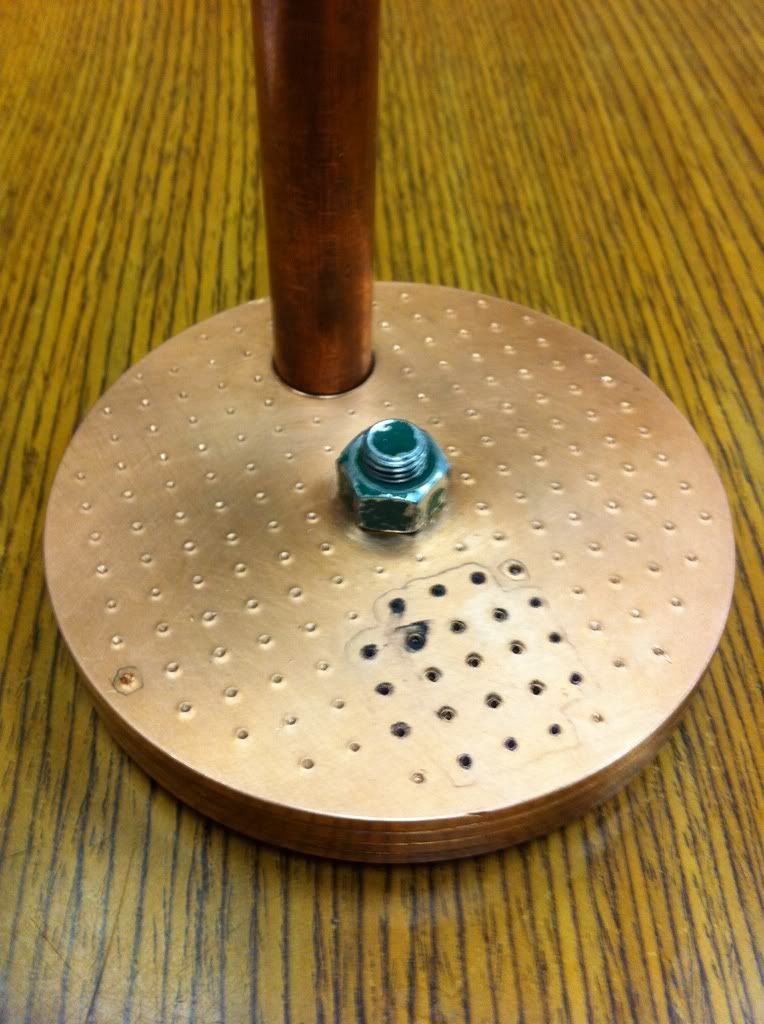

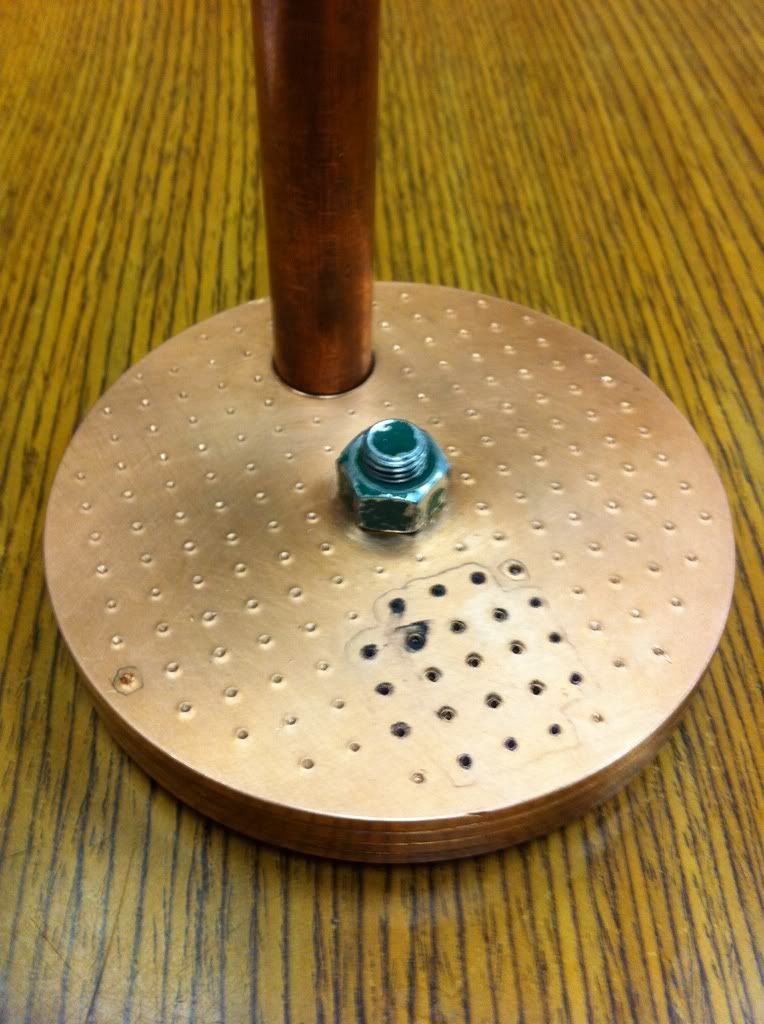

OK we are nearly there.

This is it in it's shortest mode. One column section and two plates ( I have not made the rest yet) I can't wait I must give it a go.

You could say I am going to learn to play my flute one note at a time.

Tomorrow morning I will do a cleaning run and if time permits I have a sugar wash ready to go.

All the bits

assembled

Regards

Re: FLUTE TALK

Posted: Sun Feb 27, 2011 11:05 pm

by olddog

Let us know how your flow meter works out with a Flute.

BTW Great looking build, can't wait to here the results of your first run.

OD

Re: FLUTE TALK

Posted: Mon Feb 28, 2011 4:34 am

by LWTCS

Yes, really good looking build.

There are a bunch of really well put together builds round here. Really has raised the bar this last year

What kind of sugar wash PB? Got any kind of adjunct in it so you can gage your flavor?

Ah no matter,,,I'm sure it will be as it should.

Re: FLUTE TALK

Posted: Mon Feb 28, 2011 5:33 am

by exon

Very impressive PBY !

Great looking work.

exon

Re: FLUTE TALK

Posted: Mon Feb 28, 2011 11:54 am

by rad14701

Real nice craftsmanship, prdbrissy... I especially like the modified keg top... Looking forward to hearing how the rig works when completed...

Re: FLUTE TALK

Posted: Mon Feb 28, 2011 3:36 pm

by Prairiepiss

Great looking build prdbrissy.

1 question? Am I not reading your post right or am I missing something? You said this is the smallest configuration with one column section and two plates. That's where I got lost. Are you going to be running two plates? If so where will the second one be placed? I know the one will be between the bottom reducer and the column section. Is there enough room under the dephlagmater for the second plate to be placed on top of the one column section you have?

Or were you just saying you had two plates built?

I do know that you will be adding more column sections and plates as you get them built. My question above is just about the above-mentioned post that said you were going to run it like this.

Re: FLUTE TALK

Posted: Mon Feb 28, 2011 4:42 pm

by prdbrissy

Prairiepiss wrote:Great looking build prdbrissy.

1 question? Am I not reading your post right or am I missing something? You said this is the smallest configuration with one column section and two plates. That's where I got lost. Are you going to be running two plates? If so where will the second one be placed? I know the one will be between the bottom reducer and the column section. Is there enough room under the dephlagmater for the second plate to be placed on top of the one column section you have?

Or were you just saying you had two plates

There is a plate at each column joint. Therefore in this configuration there is a plate above and a plate below the window( sight glass). The dephlegmater condenser starts about 75mm up from the column section joint.

I did the cleaning run this morning. I have a small water leak in one of my water lines to fix and I think I will reduce the size of the holes in the plates from 2.5mm dia to 1.5mm dia before I run the wash. Unfortunately that want be till next week now.

Regards

Re: FLUTE TALK

Posted: Mon Feb 28, 2011 5:59 pm

by Prairiepiss

Oh ok I thought the dephlagmater started at the joint. Sory I was confussed!

Re: FLUTE TALK

Posted: Mon Feb 28, 2011 6:11 pm

by RayDean

Finally starting to make some progress!

Machining done on 4" to accept the stainless ferrules.

Main column off to the welder. I know the sight glasses are too long, but it's hard to argue with free.

Dephleg cooler dry fitted

Condenser dry fitted.

Re: FLUTE TALK

Posted: Mon Feb 28, 2011 6:41 pm

by WalkingWolf

Nice work RayDean -- it is nice to see I'm not the only one that resorted to getting a machinist to cut down the damn copper for the ferrules to fit. Look forward to hearing how it turns out for you.

Re: FLUTE TALK

Posted: Mon Feb 28, 2011 6:54 pm

by WalkingWolf

Ah Spook -- that shit bout had me giving up on the column all together. I guess I got the thickest copper cause they weren't even close. They weren't even close even after working on them for several hours with a file. Was happy as a clam after I got them cut -- He left them 5'thousandths or so undersized (or something like that). I had to tap them pretty good to get them in but it went really well.

Re: FLUTE TALK

Posted: Mon Feb 28, 2011 7:03 pm

by Mr.Spooky

after my last flute build,,, i had about 20 hours with a hand file

,, that aint hapinin again.... i went to get a 4" ferreul welded to a keg today and the owner of the shop called me back and said " we have a problem,, the kegs aluminium",,, i thought to myself,, bullshit, ,so i told him to check his facts.. as it would have it,,, its S.S!!!! recon his fabricator just thought that a beer keg was made out of the same stuff as beer cans

.. anyway,,,, i guess the moral to my story is no matter wich path ya take,, theres gonna be somekinds of stones in the road

spooky

Re: FLUTE TALK

Posted: Mon Feb 28, 2011 8:31 pm

by RayDean

Thanks for the encouragement guys, I needed it. Everythinghas been really smooth sailing so far, but tonight I started on the sieve plates. I've gone so far as to center punch all if the holes, but after breaking 4 bits without a single successful hole through all 4 plates I'm thinking that I've exceeded my talent level. Thinking about going back to my original plan of a valve tray using rivets.

Re: FLUTE TALK

Posted: Mon Feb 28, 2011 8:53 pm

by prdbrissy

RayDean wrote:I've gone so far as to center punch all if the holes, but after breaking 4 bits without a single successful hole through all 4 plates I'm thinking that I've exceeded my talent

Drill the holes in one plate then use it as a template to drill thru another and so on. Dip the drill in water before drilling each hole.

Regards

Re: FLUTE TALK

Posted: Mon Feb 28, 2011 11:58 pm

by Kentucky shinner

I drill them 2 at a time.. Use some WD40 spray your bit just a little while your drilling go slow and dont force your bit.. Let it do the work. You will be fine.

Re: FLUTE TALK

Posted: Tue Mar 01, 2011 12:04 am

by olddog

Using a drill press, I have done up to 6 at a time, you have just got to take it steady and have a sharp drill bit.

OD

Re: FLUTE TALK

Posted: Tue Mar 01, 2011 12:19 am

by Austin Nichols

olddog wrote:Using a drill press, I have done up to 6 at a time, you have just got to take it steady and have a sharp drill bit.

OD

I tried and failed with the drill press OD, had brand new bits too, but my plates were 3mm thick.

Ended up drilling them out one plate at a time, one hole at a time, seemed like 300,000 holes

I am trying to let it age nice and slowly no touching for 3 months min, Shit it's hard but when it smells so bloody good, Lucky I have a good supply of my Pot Still UJSSM

95% straight away

Holey snapping duck shit batman far out

During the run I saw 96% it actually floated between 95% and 96% throughout the whole run.