I got the 2" ball valve for free. I know this is overkill.

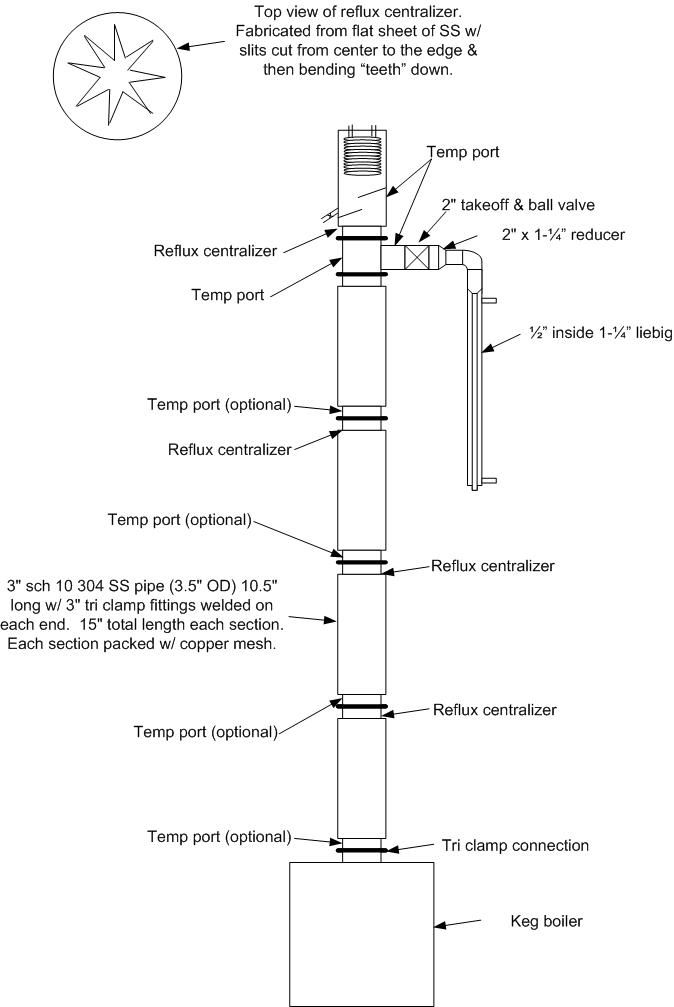

I've already built three of the column sections along with the slant plate condensor head on top. It's quite nice to be able to break down the sections easily for cleaning and storage. For the VM takeoff, I will weld two 3" tri clamp ferrules together and then weld a 2" coupling on the side. I will make up the ball valve to the 2" coupling with a close nipple.

The only part of this build I'm questioning is the condenser. I already have a 1/2" inside 1-1/4" liebig that I can use. Is the 1/2" going to be too small? I have read many posts on this subject and can't say for sure that I have seen 100% conclusive evidence that the smaller size will have a big impact on takeoff rates. It really wouldn't be a problem to make a 1-1/4" inside 2" liebig instead.

I was also considering building a shotgun condenser to go on the VM takeoff as shown here:

The vapor would be on the shell side and the cooling water on the tube side.

So the question is: what condenser would give the highest output of the highest ABV, 1/2" inside 1-/4" liebig? 1-1/4" inside 2" liebig? or 2" tube in shell condenser?

Thanks in advance for any input!