Page 1 of 1

My First Still Help!!!!

Posted: Sat Sep 18, 2010 6:13 pm

by aussiealex

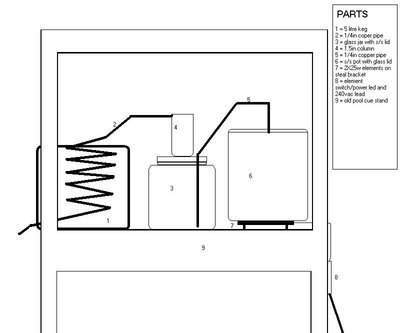

hi to all im new to this site i made my first still this week and i think i got it right this is a basic pic of it

any comments are welcome as this is my first

- This is a diagram of my first still (built on fri 17 sep 2010)

This is a diagram of my first still (built on fri 17 sep 2010)

i went to run it for the first time on Friday and it didn't go so well sprung a leak in cooling tower and then the seal on the pot ( was just gaffa taped ) it was working as i was watching the thumper bubble when the pot was hot but nothing came out of the condenser and the stuff in the pot smells like it would put hair in ya chest with 1 sip

so my ????? is

1.) what would i be able to use for the seal on the pot that will not contaminate my alcohol (would a rubber seal and then tape be fine)???

2.) will my still work ???? (in your opinion)

Re: My First Still Help!!!!

Posted: Sat Sep 18, 2010 6:31 pm

by Dnderhead

glass lids?

glass jars?

1/4 (6mm) pipe?

better do some reading.before you make something toxic or some fireworks.

Re: My First Still Help!!!!

Posted: Sat Sep 18, 2010 6:38 pm

by blanikdog

aussiealex wrote:... 2.) will my still work ???? (in your opinion)

At the risk of being blunt, NO! Or not very well anyway. Dunder has summed it up pretty well, if not perfectly.

Stay Safe.

Re: My First Still Help!!!!

Posted: Sat Sep 18, 2010 6:50 pm

by cob

"gaffa tape" ? gaffers tape ? for a seal on the boiler ? cob

Re: My First Still Help!!!!

Posted: Sat Sep 18, 2010 10:18 pm

by aussiealex

hey again

as i have run this for 6hrs or so and the only reason i can see making it not work

the seal on the pot not sealing and pressure escaping

i have been researching on the net can u enplane y this is a bad idea

Re: My First Still Help!!!!

Posted: Sat Sep 18, 2010 10:23 pm

by still crazy

Your trying to force heated vapor through a 1/4 Tube

More volume than there is pathway so your building pressure BIG NO NO so your alcohol in vapor form is dissipating out your boiler lid <<<<DON'T LIGHT A CIGARETTE if you like your eyebrows

Oh and the fact that your running it after Blaniks and Dunders warnings shows you probably won't understand what I said either.

Whatever you do don't touch the red button!!!!

Re: My First Still Help!!!!

Posted: Sat Sep 18, 2010 11:07 pm

by aussiealex

i ran it b4 i put this post up in a well ventilated place

there is not much pressure in the boiler because the heat is lower than normal

pot 7.6l

thumper 2l

on a low heat should not create much pressure as the slower vaporisation just means longer time to distill say 5l wash

Re: My First Still Help!!!!

Posted: Sat Sep 18, 2010 11:32 pm

by 0re0

I'll do a little bit better than just scolding you, and telling you to read more.

Make sure you read these article before you kill yourself or anyone else.

And when you think that you got the basics covered read more.

Re: My First Still Help!!!!

Posted: Sun Sep 19, 2010 6:19 am

by aussiealex

to start with thanks to 0re0 much better than every 1els

ok now i have done some more reading on basic pot stills and thumpers from this site and others

can some one tell me if this is correct or not

1.) 1/4 inch copper pipe is this ok for a small pot still ? ( seen heeps of ppl say its ok )

2.) glass thumper ? ( seen quite a few of them on this site and ppl say its all good)

is one of the reasons for my still being bad the column on the thumper

i know most of you all said

"glass lids?

glass jars?

1/4 (6mm) pipe?"

and have read the articles 0re0 said to read and i don't see the problem

the only problem i can see is the seal on the lid (but im gonna change the lid to a s/s lid and hold it in place with a s/s ring with 4 springs coming off it too where the handles were on the pot )

please help as i have put alot of spare time in to reading the posts on here and alot of other ppl have used similar stuff

and said it works and didn't get blasted so is part of the reason also because i said it didn't work properly

thanks again all

Re: My First Still Help!!!!

Posted: Sun Sep 19, 2010 6:32 am

by Kentucky shinner

You need to make you a flour paste to seal your top. It works amazingly well, get rid of the tape. If you loosing anything at all from around your lid, that is all alcohol vapor. In my opinion you need to use at least 3/8" coming off your boiler, personally if it were me I would use 1/2". The 1/4" may work but don't throw to much heat at it, that will cause pressure to build up with such a small take off. Personally I would ditch the glass thumper. If you gonna use a thumper I would build me one form copper or stainless or order you a small wood keg and make one.

If you loosing any vapor at all from around you lid SHUT DOWN Immediately

Be careful man,, your working with very flammable Vapor that you cannot see..

KS

Re: My First Still Help!!!!

Posted: Sun Sep 19, 2010 6:59 am

by Dnderhead

I thank you better go back and read those articles again, tho some use glass most all frown upon the use . (and if used should be tempered/Pyrex type)

simple GLASS BRAKES . broken /leaking parts and hot ethanol can be disaster ,even at low proof if heated.

small tubing for lyne arm/condenser can /will build up presser and vapor speed both of witch you do not want.

1/4 tubing mite handle 2 hundred watts? that I'm not sure of, others in engineering would be better qualified to answer that

but to put it in layman's terms ,you want the vapor coming out of your still in a "lazy"manner not blowing out like a boiler

for a steam engine.

Re: My First Still Help!!!!

Posted: Sun Sep 19, 2010 7:05 am

by aussiealex

hey thanks for the input im using 1/4in for that reason (only 2x25 w elements w/max temp of 94 degrees Celsius taking 2 hrs or so to get to temp depending on how much wash is put in still) i think im gonna take the thumper off and just have it as a standard pot still or making a triple thumper out of some 2in pipe at 150ml high and having it sit on the side of the pot so they heat a bit quicker as the pot does not get to boiling point for the water

how would i go about making the paste that u were talking about

ps i have had just water in it to do a test and water dose not boil but almost so the pressure is not that high i will re make the still tomorow morning and do a full test run with just water would that be a smart thing to do

and i also bottled the wash that was in the still (what i went to run on friday arvo) and it looks alot clearer than what it was when i put it in

Re: My First Still Help!!!!

Posted: Sun Sep 19, 2010 7:16 am

by Austin Nichols

aussiealex wrote:

how would i go about making the paste that u were talking about

Flour and water 50/50 then thicken if needed, consistancy of goo is about right.

I used it today to seal a leak in the alcohol path, it worked great.

Cheers.

Re: My First Still Help!!!!

Posted: Sun Sep 19, 2010 7:20 am

by aussiealex

thanks austin ill try that

Re: My First Still Help!!!!

Posted: Sun Sep 19, 2010 7:42 am

by rad14701

Welcome to the HD forums, aussiealex...

PLEASE do us all a favor and do the research as has been suggested by your fellow members... We aren't going to hand-hold or spoon-feed you every step of the way... The still you have slapped together is just plain dangerous and inefficient... Any amount of research should enlighten you of these facts... Your dialog here proves that you haven't done enough research... We are here to help you along and keep you, your friends, and family safe...

Stainless steel and copper... No glass, rubber, or plastics...

We aren't going to help those who aren't wiling to help themselves... Simply because we didn't approve of what you thought was a satisfactory still doesn't negate our concerns for your safety...

Scrap the ghetto still idea, do your research, and build a safe still if you are really interested in this hobby... Otherwise, find another hobby or go where folks don't care whether you use inferior components and don't listen to folks who have many years of hands on experience...

I don't mean to come off like I don't want to help you because I am helping you by being blunt rather than treating you like a fragile child... People have been trying to help and it appears as though you are just trying to shun their efforts...

NUFF SAID...

Good luck... Stop by the Welcome Center and give us a proper introduction...

Re: My First Still Help!!!!

Posted: Sun Sep 19, 2010 8:46 am

by 0re0

you're welcome aussiealex

I like to try to contribute where I can.

But I'll also share this with you....pay attention now

If you got more questions in particularly about how to run, when to run, what to run then you haven't read enough of those pages I sent ya.

All the essential are covered in them. And keep in mind, the only intellectual genius and that was Albert Einstein. With that being said

rarely any of us became an Einstein or learned what we know by reading & studying for weeks or months. Most of us have been studying and/or brewing

for 1 year+ . Some members have been at it for decades. The old saying I was always told as a kid was "Experience is always the best teacher"

With a little essential distilling knowledge and some common sense you will get things going. How ever if you lack the latter of the two, then

stop while you're ahead.

And the reason a lot of people don't like to answer essential questions is not because they don't want to help you. It because that most lazy people will come her asking essential questions and when we do give them essential answers and direction where to find these answers they fail to read or study. They then come back to the hand that fed (so to speak) and ask for another hand out asking questions without even reading and understanding the content. A lot like a stray dog they are. Running from forum to forum, community to community. Asking for knowledgeable hand outs.

Well, enough of the smoker ramblings

So as said and said again

When you think that you've got the basics covered read them again and study more.

Re: My First Still Help!!!!

Posted: Sun Sep 19, 2010 4:27 pm

by Samohon

rad14701 has summed this up perfectly...

Close Your Still Down Now...

That there still is just damn dangerous... You could very easily cause serious harm to both you and anybody else close by...

Vapor is a very flammable gas that, once ignited, detinates in a large flash...

The pressure inside your boiler is caused by the vapour not being able to escape fast enough...

Please, myself and your fellow colleagues here at HD only want you to be safe...

@Rad... Time we had some kind of simple theory test for New Distillers to HD, so competency at a basic level, can be seen...

Gaffa tape...? Man I need a drink...

Re: My First Still Help!!!!

Posted: Sun Sep 19, 2010 8:19 pm

by rubber duck

You need to shut down and do more reassure. I want you to be safe and successful in your new found hobby.

I would start with a 1in pipe off your boiler and tapper down to a 1/2in to 3/8in worm coil, minimum of 7 turns on your coil. Skip the thumper for now, you can add one latter.

Re: My First Still Help!!!!

Posted: Sun Sep 19, 2010 9:17 pm

by aussiealex

hey guys thanks for the info and your consern the still is nolonger in action i pulled it apart this morning when i woke up

i did some maths and from what i got i thought 1/4in pipe would be sufficient so back to the drawing board i think

thanks again all

will post plans for the new 1 this weak some time am going to talk to a mate that has been doing it for about 2 and a half yrs but i dont have a ph for him so roadtrip

Re: My First Still Help!!!!

Posted: Sun Sep 19, 2010 9:43 pm

by blanikdog

I just did a search using the term 'flour paste' and got 990 posts, yet alex you grizzle about being blasted and told to read when you asked twice how to make flour paste.

It's all there, but you have to do a bit yourself. Enough said?

STAY SAFE

Re: My First Still Help!!!!

Posted: Mon Sep 20, 2010 10:25 am

by rad14701

A worm made from 1/4" tubing will choke and surge due to the wetting effect within the worm... 3/8" is the absolute minimum size for a worm and the larger the boiler and more heat input, the larger the worm needs to be... The information is all here... Calculations don't mean shit when compared to the real world practical experience of many...

Re: My First Still Help!!!!

Posted: Mon Sep 20, 2010 7:35 pm

by blanikdog

true rad.