Page 1 of 3

Mecha Still Build progress

Posted: Mon Oct 25, 2010 1:13 am

by TheMechwarrior

Thanks for all the input to date guys.

I've concluded that since this is my first build I'll keep it simple and replicate a known success story, namely the VM still.

Here's she is all in 2"

Boiler

50L stainless steel keg with a 6" triclover ferrule fitting and a 2400W stainless heating element

Reflux column = 42"

2" throughout packed with copper mesh and stainless scrubbers with a 2" to 1.5" concentric reducer at the top to act as a reflux centering device

Condenser = 13"

Double helix 1/4" stainless coils

Vapour management

2" to 1.5" T to a 1.5" stainless ball valve (I already had this - would have liked it to be a gate valve...)

Leibig = 36"

Triple wall design with 2" outer...still sorting the sizes of the other tubes to insert...advice welcomed.

Still to do

- Finish the drawing for the leibig and construct

- Build heating controller - currently just on/off control

- Listen to advice and make improvements

- Make and drink lots of grog - got the second part of that mastered

And the top of the keg looking inside to the stainless heating element

Re: Mecha Still Build progress

Posted: Mon Oct 25, 2010 2:42 am

by HookLine

That should work. Mine only has a 1" take off port and it works okay.

But if you can swap that tee for a 2 x 2 x 2", and then reduce the 2" branch down to 1.5 before the valve, it will get higher maximum take off rates (ie with the valve wide open).

You have the advantage of a modular construction, so you can change it easily later.

Re: Mecha Still Build progress

Posted: Mon Oct 25, 2010 2:48 am

by maheel

Is that the "no weld SS element" type thats on AUD ebay @ around $50

eg drill hole and pass through from opening and tighten

if yes have you tested etc (thoughts) as i am interested in buying one....

looks mighty pretty

Re: Mecha Still Build progress

Posted: Mon Oct 25, 2010 3:04 am

by TheMechwarrior

maheel wrote:Is that the "no weld SS element" type thats on AUD ebay @ around $50

eg drill hole and pass through from opening and tighten

if yes have you tested etc (thoughts) as i am interested in buying one....

looks mighty pretty

Yes that's the one. I got mine from

http://www.kegking.com.au" onclick="window.open(this.href);return false;" rel="nofollow.

As the fittings that come with it are perpindicular and not concave/convex I was a little cautious about getting an air-tight seal so I had a flat plate welded to the inside of the keg. I'm sure that with a soft seal (as supplied) you would get a good seal...for a some period of time. But I wanted to replace the silicon seal with a PTFE and these have little to no give so I needed a flush mounting surface.

I have no reason to doubt the suppliers regarding the ease of installation and use of this heating element. I may go a little overboard but I see this as a lifetime investment that will be passed down to the next generation etc. I want it to last.

Image below:

Re: Mecha Still Build progress

Posted: Mon Oct 25, 2010 3:16 am

by HookLine

Also suggest splitting the column into two sections, about 28 and 14". The short one will be useful for a pot column.

Re: Mecha Still Build progress

Posted: Mon Oct 25, 2010 3:39 am

by TheMechwarrior

That's awesome Hookline thanks!

I actually have a spare section of 2" complete with ferrules and it's 14"!

I had it built as a second condenser for an earlier idea I was working on and now I have a purpose for it!

I love it when a plan comes together...eventually

Everyone happy that my Leibig will be long enough for both VM and stripping functions?

Suggestions for internal tube sizes of the triple walled design?

I'm thinking 1.5" inside 1.75" inside 2" but I'm open to suggestion.

Cheers,

Mech.

Re: Mecha Still Build progress

Posted: Mon Oct 25, 2010 3:52 am

by maheel

Re: Keg element

many thanks for the detailed review / info / photo

great thinking on the plating, i have seen a few that "hit the keg with a hammer to flatten " ideas.....

another item for the xmas list

it's a great looking build

Re: Mecha Still Build progress

Posted: Mon Oct 25, 2010 4:03 am

by Austin Nichols

That keg is just screaming for a flute, I want it

The rest of the build is nice, now hurry up and put it together so you can run the bloody thing

Very very nice.

Re: Mecha Still Build progress

Posted: Mon Oct 25, 2010 4:12 am

by TheMechwarrior

Austin Nichols wrote:That keg is just screaming for a flute, I want it

The rest of the build is nice, now hurry up and put it together so you can run the bloody thing

Very very nice.

Thanks Austin, I'm also a Kevin Fan, saw him live in January last year down here in Tasmania.

I saw the gloriously beautiful and artistic flute that olddog put together and I figured I'd better keep a nice size opening at the top of my keg for future projects....the flute is on the list

Re: Mecha Still Build progress

Posted: Mon Oct 25, 2010 4:22 am

by HookLine

TheMechwarrior wrote:Everyone happy that my Leibig will be long enough for both VM and stripping functions?

Suggestions for internal tube sizes of the triple walled design?

I'm thinking 1.5" inside 1.75" inside 2" but I'm open to suggestion.

I do not know enough about the thermal performance of stainless to give a definite answer about the stripping runs, though I think it will handle them. It will certainly handle your neutral runs.

Ask manu, he is the stainless guy here.

Re: Mecha Still Build progress

Posted: Tue Oct 26, 2010 7:01 pm

by TheMechwarrior

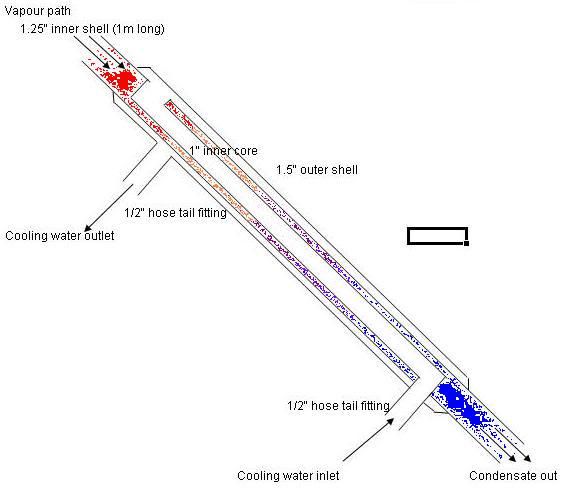

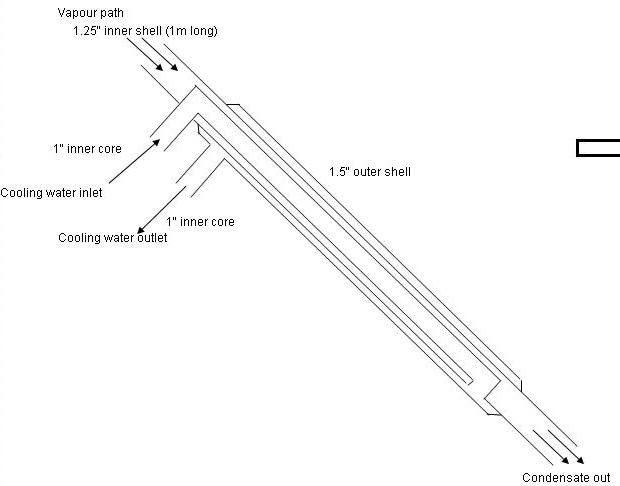

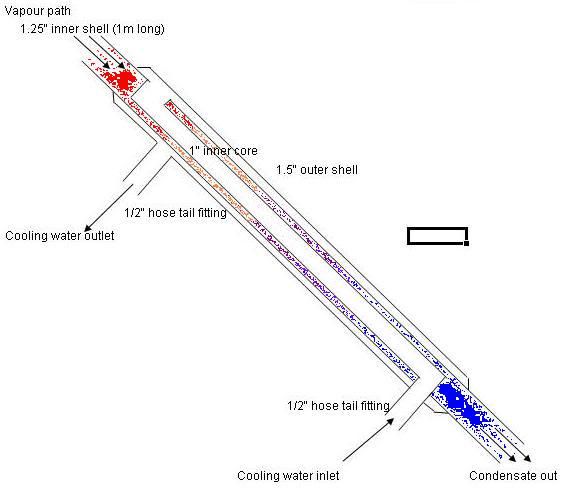

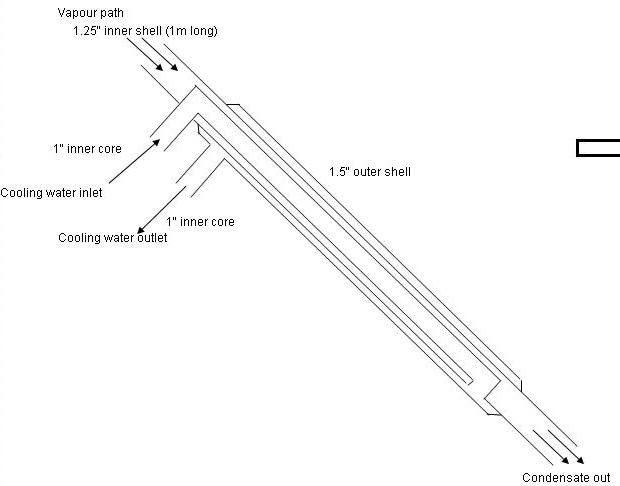

Here's the drawing of the Leibig:

Re: Mecha Still Build progress

Posted: Sun Oct 31, 2010 9:12 am

by NineInchNails

TheMechwarrior

All those great parts and all the possibilities! Amazing collection man. Versatile as hell and built to last.

Re: Mecha Still Build progress

Posted: Sun Oct 31, 2010 11:21 am

by NcHooch

TheMechwarrior wrote:

I may go a little overboard but I see this as a lifetime investment that will be passed down to the next generation etc. I want it to last.

Nice! ....you should name it the heirloom

Lookin good Mechwarrior, Keep up the good work,

NChooch

Re: Mecha Still Build progress

Posted: Sun Oct 31, 2010 12:50 pm

by Braz

TheMechwarrior wrote:Everyone happy that my Leibig will be long enough for both VM and stripping functions?

Suggestions for internal tube sizes of the triple walled design?

I'm thinking 1.5" inside 1.75" inside 2" but I'm open to suggestion.

That liebig will do just fine. I'm running a 22" single wall 3/4 over 1/2 which is a lot less than what you are doing and mine will handle my stripping runs, but just barely. My distillate comes off at 90+F which is a little hotter than I'd like.

Re: Mecha Still Build progress

Posted: Sun Oct 31, 2010 3:43 pm

by TheMechwarrior

1st double helix condenser coil attempt.

3m of 1/4" resulted in 14 inner windings and 14 outer windings and a total condenser height of ~190mm

Thanks for the awesome tutorial Hook

Now for the Leibig, just waiting on the 0.9mm walled stainless to arrive.

Re: Mecha Still Build progress

Posted: Sun Oct 31, 2010 5:55 pm

by HookLine

TheMechwarrior wrote:1st double helix condenser coil attempt.

[snip]

Thanks for the awesome tutorial Hook

My pleasure. Glad folks find it useful.

Nice work on the condenser. It could use a little straightening, though it is not strictly necessary. Be careful if you do it.

Re: Mecha Still Build progress

Posted: Sun Oct 31, 2010 7:42 pm

by TheMechwarrior

HookLine wrote:

Nice work on the condenser. It could use a little straightening, though it is not strictly necessary. Be careful if you do it.

Honestly I wasn't expecting it to work out at all being my first attempt so when it came out the way it did I was over the moon with joy!

I may poke at it a bit more to see if I can straighten it up but since I need to build a couple more I'm sure the 2nd and 3rd will be better. If that's the case I'll use this as a pre-condenser.

Your tutorial made life real easy, I cut the mandrels to the size you said. I mounted the inner mandrel in a vice as I seemed to run out of hands, this also gave a locking point for the tail of the coil easing the load on my left hand. Right hand happily winding away as it all appeared before me.

Re: Mecha Still Build progress

Posted: Sun Oct 31, 2010 11:50 pm

by TheMechwarrior

Leibig being built now based off this drawing...on second thoughts I think I should move the cooling water outlet to the bottom...will fix that tomorrow before it's too late.

Re: Mecha Still Build progress

Posted: Mon Nov 01, 2010 12:13 am

by gretschem

I have read that cooling water inlet on leibigs is the bottom inlet ???

So your drawing seems correct

Cheers

Re: Mecha Still Build progress

Posted: Mon Nov 01, 2010 12:14 am

by olddog

gretschem wrote:I have read that cooling water inlet on leibigs is the bottom inlet ??

Thats correct

OD

Re: Mecha Still Build progress

Posted: Mon Nov 01, 2010 12:42 am

by TheMechwarrior

Roger that.

I want to move the cooling water outlet to the bottom as well, next to the inlet.

This is to keep the water moving thoughout the unit.

Re: Mecha Still Build progress

Posted: Mon Nov 01, 2010 2:30 am

by HookLine

In a standard double walled (single pass) Liebig the coolant flows one way, and the coolant inlet should be at the bottom and outlet at the top.

The situation for a triple walled (double pass) Liebig is different (for the particular design Mech is using, at least). The water in it flows both ways (up and then back down, or vice versa) with the coolant inlet and outlet both being at the same end.

Re: Mecha Still Build progress

Posted: Mon Nov 01, 2010 2:59 am

by TheMechwarrior

I'm not entirely happy with the water flow in the design...

Hook,

I'm considering trying to pull this off

I was thinking of using your 16mm inner mandrel idea as the coil diameter but winding the coil down the tail to create the cold finger rather than away from the tail as we do for the double helix coil.

This coil would then be contained within the 32mm vapour path and this would be surrounded by the 38mm outer cooling jacket.

Your thoughts on this?

Cheers,

Mech.

Re: Mecha Still Build progress

Posted: Mon Nov 01, 2010 3:58 am

by HookLine

Nice drawing. You do that?

If you are going to go to that much trouble, you could instead do a double parallel coil set up inside a shell, a double coil Graham condenser maybe? More surface area, and coolant flow is in the same direction.

Re: Mecha Still Build progress

Posted: Mon Nov 01, 2010 4:08 am

by TheMechwarrior

Not my pic mate, direct from Sigma that one.

I understand the 2 different configurations of a Graham condenser but you've lost me with the double parallel. Can you explain in pictures?

Re: Mecha Still Build progress

Posted: Mon Nov 01, 2010 3:53 pm

by TheMechwarrior

This Graham condenser looks easier to build than the triple walled leibig:

Still unsure Hook about the ideas you were suggesting? Can you elaborate further?

Re: Mecha Still Build progress

Posted: Mon Nov 01, 2010 5:11 pm

by Kentucky shinner

The Graham is very efficient.. I think it will sever you very well.

KS

Re: Mecha Still Build progress

Posted: Mon Nov 01, 2010 9:33 pm

by HookLine

TheMechwarrior wrote:This Graham condenser looks easier to build than the triple walled leibig:

Still unsure Hook about the ideas you were suggesting? Can you elaborate further?

Same as that, just using two coils in parallel. In theory it should give you double the condensing capacity, provided your coolant flow can keep up with it. Like this:

You could also interweave the two coils to form a double helix.

Re: Mecha Still Build progress

Posted: Mon Nov 01, 2010 9:41 pm

by myles

I have a couple of these multi wall liebigs in both configurations, but I connected mine up with the water flows in parallel. Instead of flowing down 1 coolant path and up the other, the coolant paths are both contraflow to the vapour path. That spiral inside a libig will be hard to build as it is shown in the diagram.

Re: Mecha Still Build progress

Posted: Tue Nov 02, 2010 5:41 am

by rad14701

For our application a single coiled Graham condenser should suffice... No need making the compact "worm in a bucket", which is essentially what a Graham condenser is, in miniature, more complicated than it needs to be...

All those great parts and all the possibilities! Amazing collection man. Versatile as hell and built to last.

All those great parts and all the possibilities! Amazing collection man. Versatile as hell and built to last.