Page 1 of 1

my next build,, double boiler/steam

Posted: Fri Jan 20, 2012 8:15 pm

by itchy

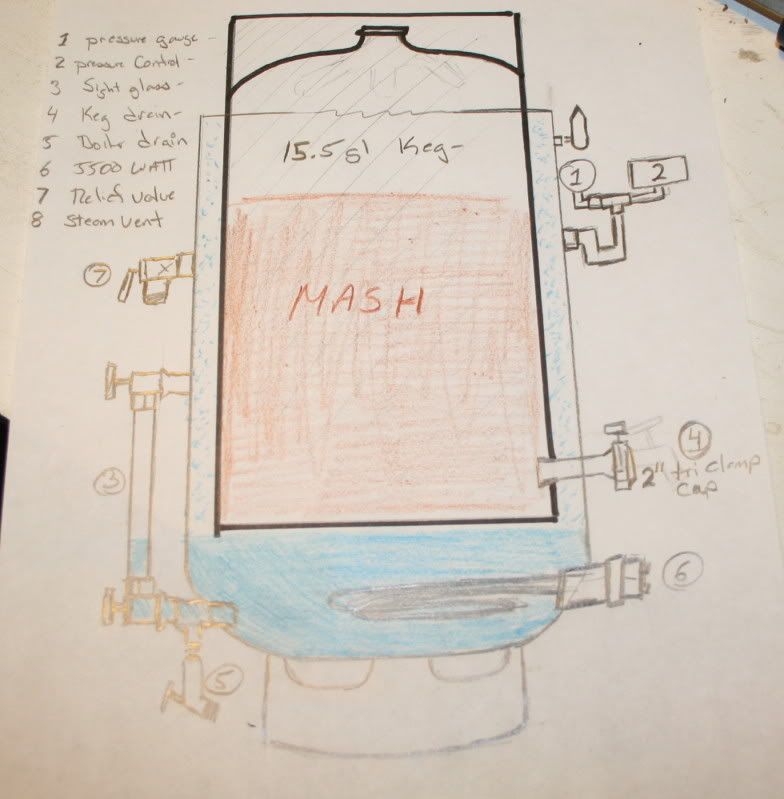

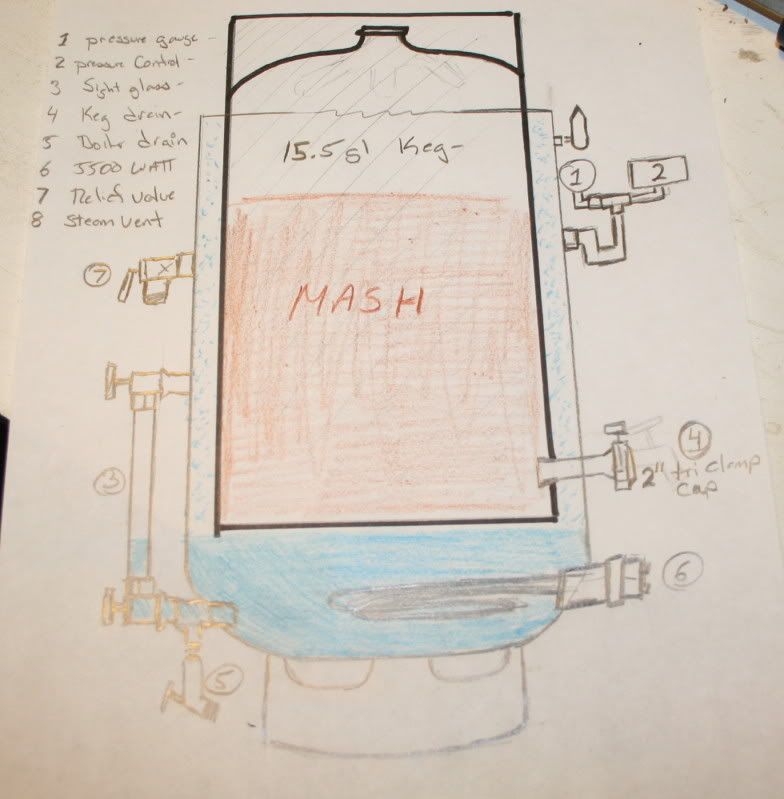

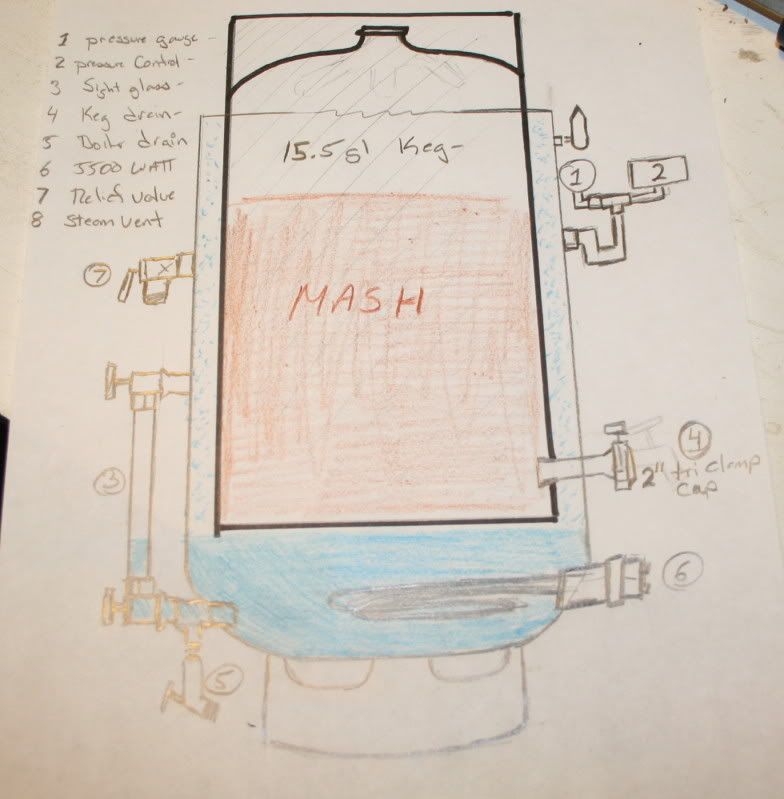

i havn't given up on this steam powered boiler idea. i been tossing around ideas and trying to collect parts,, this is what i have come up with so far,, if any of you remember that nitrogen/co2 tank i cut up awhile ago i'm gonna use the inner tank from that tear down as my boiler body,, its all stainless steel with 1/8" wall thickness so i know its strong enough to handle the pressure of steam. I'm gonna try it at approx 25 pounds of steam pressure at first,, i found that a 1/2 keg fits inside the co2 tank pretty good with 1 1/8" clearance all the way around and i'm gona have to raise it up about 6 inches so the element can fit underneath it. i collected a element, all my adapters that i will need,, the drain valves and the sight glass, i also got a used but almost new pressure control but it tops out at 10 psi.. i might be able to reset the spring (like you do on 20/40 well controls) to get higher pressures out of that control. i actually got two of these controls so the second one will be added on as a extra safety along with a immersion type aquastat control.. (these two extras are not on my sketch) since i will be distilling on the grain i went with a 2" tri clamp and a cap to use as a wash out drain port.. (regular drain valves would get clogged up) if this works out as i plan then i will be selling off my other two boilers,, the 30 gallon tank and the converted 1/2 keg and just sticking to this boiler with changeable heads. weather permitting i'll be starting fabrication tomorrow and i will continue to add to this thread until its completed and tested. so bear with me as this will take some time,,

here is a picture of the keg resting in its future home.. i hate to weld it all together but theirs no other choice... kegs are so hard to find....

it won't be raised up quite this much but it gives you the idea of what im doing,, i gotta cut a large ring to cover the gap between the two tanks and weld it all up with no leaks,, i'll pressure test it all with just air to 50 psi so im well beyond my Target pressures..

my basic design that i will be adding onto as parts come available,,, wouldnt a nice flute just top this off reall nice?

Re: my next build,, double boiler/steam

Posted: Sat Jan 21, 2012 7:24 am

by ozone39

I would test with water (hydrotest) if your going to go up to 50 psi.....As well a secondary high limit switch is always a good idea with steam....

Re: my next build,, double boiler/steam

Posted: Sat Jan 21, 2012 7:39 am

by stillenand chillen

hay itchy I have 2 kegs here (maybe we can work something out)

, I know your drawing is a rough scetch but put that keg drain close to the bottom as possable , makes for ez cleaning

Re: my next build,, double boiler/steam

Posted: Sat Jan 21, 2012 8:20 am

by junkyard dawg

x2 on the hydro testing. Its much safer than testing with air pressure. Looking forward to see how this plays out...

Re: my next build,, double boiler/steam

Posted: Sat Jan 21, 2012 8:26 am

by Sungy

Wow very creative. I must caution you running 25 psi steam pressure. 10 to 15 psi is plenty. Most steam boilers are rated for 15 psi steam. Above that you are classified as a high pressure boiler and require more saftey controls. Water expands over 600 times its size when it changes state from liquid to vapor. Boiling point at atmospheric pressure ( 0 psig or 14.696 psia )is 212 'f. When you add pressure to the liquid you raise the boiling point. Meaning that you will still have water at 15 psig (30 psia )but the boiling point rises to 250 'f at 25 psig (40 psia )the boiling point raises to 267 'f ( same as a pressure cooker )

Look at the steam table (measured in psia) I attached if you have questions

http://www.sapiensman.com/conversion_ta ... _steam.htm

Re: my next build,, double boiler/steam

Posted: Sat Jan 21, 2012 10:13 am

by itchy

@ sungy thats exactly why i wanted to hit 25 psi,,, at 250 degrees theirs plenty of heat to bring the 12 gallons of mash to temperature at a reasonable time,, if i would use 10 psi it would take hours to get the mash to boil.. ozone39 runs 30 psi in his steam unit and it takes him about 45 minutes to bring 10 gallons to a boil...

hydro testing it is,,, but i gotta get started on this thing... been sleeping all day..

Re: my next build,, double boiler/steam

Posted: Sat Jan 21, 2012 8:47 pm

by itchy

Re: my next build,, double boiler/steam

Posted: Sun Jan 22, 2012 7:24 pm

by itchy

finally i got some time today and spent it out in the shed,,, it may not look like much but i think i made a lot of progress on this today,,, i welded 3 all thread couplings to the bottom rim of the keg to hold it in position when it sits in the boiler body and i brazed on a 1 1/4 copper pipe to the center of the bottom for a keg drain/washout hole.. this pipe will go straight thru the bottom of the boiler and turn with a 90 degree elbow to a ball valve.. i got all my holes cut and the female couplers are all welded into place.. all i have left in regards to welding is to drop the keg into the main body and weld that ring all the way around sealing the boiler from the keg and hopefully its air tight. i'm planning on wiring the controls in low voltage (24 volts) and having that circuit close a 2 pole 30 amp contactor... that contactor will then send 220 volts to the element,, when it hits my target pressure the circuit will open turning off the contactor killing power to the element... pretty simple actually... im going to use the primary pressure switch with a secondary as a back up,, then i'm gonna go overboard and use a aquastat as a third backup kill switch.. i'll be running a 4500 watt element to power it all up. with a mixture of distilled water and glycol in the boiler.. heres a picture of todays progress. keep in mind that the beer keg is upside down.

Re: my next build,, double boiler/steam

Posted: Mon Jan 23, 2012 8:23 pm

by ozone39

One thing on the safety relief, make sure it is rated for steam...The ones for hot water (hydronic systems or hot water makers/heaters) have a rubber disk, steam rated have both a brass disk and seat. The rubber disk cannot hold up to the temps of steam....As for the glycol in the boiler water I would run just distilled water, and maybe a steam rated rust inhibitor to aid in extending the life of the black iron fittings, the glycol with de-rate the efficiency of the boiler. Once the system is fired up and you pop the relief to bleed any air the system should never have to add any water/chemicals to the system providing there are no leaks (a truly tight system will stay under vacuum once it cools down if you bleed the system of air and providing there is not a vacuum relief installed and the temperature outside or the boiler stays constant). As for the steam/air vent, probably just get rid of that. System isn't big enough to worry about air in the steam (just activate the pop off at the beginning of start up), just one more thing with moving parts to go wrong.... ....In running the 24 volt system you much have an interlock relay or are you powering a 24 volt interlock breaker??? I would suggest getting rid of any relays as the contacts can weld shut....the primary and secondary safety/control devices (normally closed) are normally line voltage and wired in series then that would supply your element. If one of the safety device trips out (activates to open) it cuts out the line voltage (or you can cut the neutral to the unit in a 220 volt situation) to the element...there is no chance of an relay sticking shut....

Re: my next build,, double boiler/steam

Posted: Tue Jan 24, 2012 2:08 am

by emptyglass

You may also want to put the boiler itself under the same hydrostatic test pressure at the same time as testing the jacket, save crushing the boiler.

Re: my next build,, double boiler/steam

Posted: Tue Jan 24, 2012 5:05 am

by Washashore

Very cool itchy, can't wait to see how it turns out.

Re: my next build,, double boiler/steam

Posted: Tue Jan 24, 2012 12:00 pm

by itchy

thanks guys,, i'll probably eliminate that steam vent as suggested and my relief valve is steam rated.. i'm going with low voltage to lessen the amount of high voltage connections around the boiler,, just too much water/wash/steam around for that kinda voltage all over.. the contactor im gonna use is a heavy duty hvac airconditioning contactor,, in 30 years in the field i have replaced thousands of these but never seen one weld itself shut,, they are pretty safe as well and 30 amp rated..its not a regular relay.. i can even use a 3 phase contactor rated at 60 amps if i wanta go stronger. as for the glycol i only wanted to add enough to keep the water inside from freezing up when its stored out in the shed in the winter.. i think thats only like 5-10% glycol... and should be good to around 0 degrees f

Re: my next build,, double boiler/steam

Posted: Wed Jan 25, 2012 5:17 pm

by itchy

ok just an update,,,, everythings welded up and i pressure tested it today,,, at 45 pounds pressure no problem,, at about 48 pounds their was a loud pop kinda ding sound but it still held pressure,, it was the keg slightly imploding with all the external pressure on it,,, i let it sit a cpl hours then dropped the test,,, then i pressure tested the inner keg to see it it was damaged as the drain could of popped and it un-imploded,,,lol,,, new word their,,,,,,, so everything seems fine as im only gonna be running 20-25 pounds steam in it... im quite sure the outter shell coulda took a lot more pressure then 48 pounds.. hopefully tomorrow night i can mount the controls and get it wired up for a real test run,.... should be interesting...

Re: my next build,, double boiler/steam

Posted: Fri Jan 27, 2012 5:45 am

by ozone39

Good call on the freeze protection....Was wondering though if the heating element can handle glycol??? That stuff has a tendency to make a nasty coating when it get "cooked" to surfaces...I've seen fire tube boilers that developed a leak in them that had glycol and it a an utter mess trying to get that shit off...

Re: my next build,, double boiler/steam

Posted: Fri Jan 27, 2012 2:00 pm

by itchy

i think if im just mixing it real diluted,,, just enough to avoid freezing then it shouldnt be a issue,,, i was thinking maybe a windshield washer antifreeze or even regular car antifreeze,,, i'm gonna try to fire it up tonight with just water to see how it runs and to adjust all the controls,,,i'm just gonna dump 4-5 gallons of water into the inner keg (without a still head) to bring up to a boil,,then dump it all out.. last night i wound up cleaning it up,,, painting it with high heat paint and just mounting all the controls,ect,,,

Re: my next build,, double boiler/steam

Posted: Fri Jan 27, 2012 6:07 pm

by itchy

well not too many replys on this but i see a lot of people reading so here goes some more on this project,,,,, total success!!! i just ran the shit outta it,,,, filled the keg with 10 gallons of 56 degree f well water and another 5 gallons went into the boiler section. i wired up the controls 24 volt and just mounted the contactor and transformer to a chunk of wood,,, i'll be picking up a handy box tomorrow to mount everything in,,, so 24 volts out from the transformers up to the controls on the boiler then back down to the contactor,, the contactor pulls in putting 220 volts to the element,, when it hit 13 psi one of the boiler controls opens its circuit and kills power to the contactor killing power to the element,, a 4 pound differential closes the circuit when the pressure drops to 9 psi,,, and it heats up again,,, pretty simple.. i found that it took a hour to get the keg to boil and then the boiler hit 13 psi,,, i see no need to run any higher pressures in the boiler as i had a rolling boil in the keg.. and the boiler never hits 13 psi until the keg is at temp as well,, i guess the kegs so cold its actually condensing the steam right back to water preventing pressure build up until it heats up as well.. but a hour isn't bad getting 10 gallons to boil from 56 degrees. i'm only running a 4500 watt element in it for now.. hers a few pics,, kinda boring as theirs no still head on the keg but you can see steam coming out of it,,

now the pressure gauge has both pressure and a vacuum scale,, after a few hours the gauge should be reading a vacume as the water cools off,,,

Re: my next build,, double boiler/steam

Posted: Fri Jan 27, 2012 6:22 pm

by Washashore

Looks awesome Itchy

I must admit what you're doing is WAY over my head. I admire the MacGuyverizing

Re: my next build,, double boiler/steam

Posted: Fri Jan 27, 2012 6:25 pm

by bentstick

Is awesome, go go go teach us more!

Nice work

Re: my next build,, double boiler/steam

Posted: Fri Jan 27, 2012 6:30 pm

by itchy

sorry guys but im done on this site,,, tired of shit in my mailbox that im doing wrong,,, now my pictures are too big,,, sorry,,, dont need bs.... but thanks for the help when i needed it and i hope some of my efforts are truly appreciated... good luck guys,,, itchy

Re: my next build,, double boiler/steam

Posted: Fri Jan 27, 2012 7:44 pm

by Prairiepiss

Damnit itchy. I just read the thread and found this. Nice work.

Re: my next build,, double boiler/steam

Posted: Sat Jan 28, 2012 12:22 am

by ozone39

man...I like big pictures.....thought the build was going well....

Re: my next build,, double boiler/steam

Posted: Sat Jan 28, 2012 6:24 pm

by itchy

i had to stop back n post this,,, i ran this steam unit for almost 11 hours today,,, made some nice stock as well,,, but if anyones setting something like this up to use for stilling on the grains it works great,, but i did find that readjusting the running pressures to stay between 10-13 psi made it run real smooth,, i also set a 2 pound differential on it..

@ pp thanks dude,, much appreciated

Re: my next build,, double boiler/steam

Posted: Tue Feb 07, 2012 9:24 pm

by ozone39

hooked on steam myself here......the ONLY way to go....

Re: my next build,, double boiler/steam

Posted: Wed Feb 08, 2012 5:39 am

by eddieb

Don't let em get you down. keep posting.

Great build.