Page 1 of 1

Need help sealing water bath to the still

Posted: Thu Feb 02, 2012 11:31 pm

by liquorhacker

Hi,

I discovered this web-site last year and was amazed by the amount of information available here.

I live on West Coast in US and have been making beer for some time.

I am looking to distill some grain mash (mostly malt)

My setup

--------

I have bought a 20l still from Copper Alembic and am putting it through it paces.

Rather than use the tiny worm which came with it, I have run 30 feet of 3/8" tubing through a rubber hose and am

using that as a counterflow chiller.

I have also drilled a hole in the top and soldered a k type thermocouple so I can monitor the temp.

My trials (so far)

------------------

After cleaning it by running water and vinegar through it, I christened it with 5 liters of Chablis which I got

for $8 at Smart and Final. I was amazed to find how low the alcohol content in the wine was, because I never collected

above 35% or so (no wonder they were selling 5 liters for $8).

Next I ran some Vodka through the still and as expected got a much higher ABV. I collected till 50% or so,

with the resultant spirit being about 70%.

These were all run with the still directly fired on the gas range. But I would need indirect heat for the grain mash.

My problem

----------

When I put the still on a water bath, the temp does not go above 94 C. I slit a silicone tube along it's length and

used it to line the edge of the stock pot I was using as the water bath. The still sits on top of the tube, so I can

get a better seal. But it has not helped.

Does someone have a better idea on how to establish a better seal ? I am using a 12" diameter stock pot.

Re: Need help sealing water bath to the still

Posted: Fri Feb 03, 2012 1:25 am

by maheel

put some plain water in the still and then boil it in the water bath

if your getting distilled water then the temp should read 99/100 (or very close with steam vapour)

if it' not reading 99 on water then the probe is wrong..... so then calibrate the temp device if you can

Re: Need help sealing water bath to the still

Posted: Fri Feb 03, 2012 1:30 am

by maheel

wait......

are you saying the still sits in mid air not actually inside the water bath...just on top of the water bath pot?

and that only the bottom of the still is in contact with the steam and hot water of the still?

then your losing to mush heat to the atmosphere i reckon

if thats the issue get a bigger water bath so the whole still goes in the water...

Re: Need help sealing water bath to the still

Posted: Fri Feb 03, 2012 5:05 am

by Bayou-Ruler

welcome to the HD forum.

Re: Need help sealing water bath to the still

Posted: Fri Feb 03, 2012 9:54 am

by liquorhacker

Maheel,

Thanks for your suggestions. The bottom of the still which is curved sits on top of the stock pot so it is exposed to the steam but not in direct contact with the water.

1. The temp probe is correct because it reads 99/100 when the still is sitting directly on the gas burner

2. I have tried with a bigger pot (with a worse seal) where 3/4 of the still is in the pot, but there the temp is even lower. So I think it is a sealing issue.

I tried removing the tube and sealing the stil/stock pot edge with rye. But steam escapes from the rye and I am back to the same issue

maheel wrote:wait......

are you saying the still sits in mid air not actually inside the water bath...just on top of the water bath pot?

and that only the bottom of the still is in contact with the steam and hot water of the still?

then your losing to mush heat to the atmosphere i reckon

if thats the issue get a bigger water bath so the whole still goes in the water...

Re: Need help sealing water bath to the still

Posted: Fri Feb 03, 2012 10:40 am

by Rachiu

It will never work until will use something to rise the boiling point of water. Pressured water bath of 0,5 bar is the best idea.

Otherwise you can use cheap refined cooking oil as I do. It works well. 118*C was the highest temperature of the oil, after 7 hours of distilling at a slow rate.

I will put even a sand plate under the bigger pot.

Re: Need help sealing water bath to the still

Posted: Fri Feb 03, 2012 12:11 pm

by liquorhacker

Any ideas on how to establish the seal to create a pressure bath ?

I was hoping that the weight of the still resting on the pot with either rye dough or the silicone tubing would provide enough of a seal to reach the temperature. This would be safe too as the seal will blow if the pressure rises.

Rachiu wrote:It will never work until will use something to rise the boiling point of water. Pressured water bath of 0,5 bar is the best idea.

Otherwise you can use cheap refined cooking oil as I do. It works well. 118*C was the highest temperature of the oil, after 7 hours of distilling at a slow rate.

I will put even a sand plate under the bigger pot.

Re: Need help sealing water bath to the still

Posted: Fri Feb 03, 2012 12:43 pm

by Rachiu

You will never get pressure that way.

You have to seal by hermetic welding and 2 valves for pressure release. The valves are easy to take from a pressure cooker.

But is far much easier with oil. The level of oil must be over the level of mash.

Re: Need help sealing water bath to the still

Posted: Fri Feb 03, 2012 1:03 pm

by Fourway

Why do you feel you must have a water bath?

You can direct fire positively chunky mash if you are careful.

In a round bottom pot you can apply heat to everything except for the lowest point on the kettle and get a great efficient boil.

Re: Need help sealing water bath to the still

Posted: Fri Feb 03, 2012 3:38 pm

by rad14701

Welcome, liquorhacker...

I think we need pictures before we can be of much more help... Something just doesn't sound right... I'm with Fourway regarding scrapping the whole double boiler idea... Theres good reason why you don't see more members here using that method...

Good luck, and stay safe...

Re: Need help sealing water bath to the still

Posted: Fri Feb 03, 2012 11:32 pm

by Rachiu

Fourway wrote:

In a round bottom pot you can apply heat to everything except for the lowest point on the kettle and get a great efficient boil.

Interesting!

3-4 cm sand on the buttom of the pot and there will be no scorching and no need for double boilers and so on.

It's the simplest method which is practiced at the countryside.

Re: Need help sealing water bath to the still

Posted: Sat Feb 04, 2012 2:33 am

by Dnderhead

this is not really the place for this but 2 ways that i know work. a false bottom,,or a strap heater.

either way or any way you heat you have to be careful as not to burn if there is suspended trub/particles in the wash/mash.

that is the object of a double boiler or even steam.with water you can only heat to 212f no matter much "fire" you throw

at it. with steam it can be higher but limited by the pressur of the steam.I do not remember exactly but its something like 15-20lb

rise above atmosphere to reach 250f? this takes one hell of a rugged pot,more than any you will fiend in consumer goods.

and then if any thing happens you will be in real hot water not just from explosion but in most places it whould be considered

a hi pressure device and who ever constructs it needs to be certified.

Re: Need help sealing water bath to the still

Posted: Sat Feb 04, 2012 3:55 pm

by liquorhacker

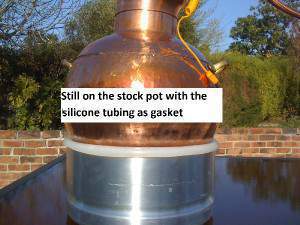

I agree a picture is worth a thousand words. Here are some images of what I've been trying.

I don't have to use the double boiler, but how do I avoid scorching ?

- Still on the stock with silicone tube as gasket

rad14701 wrote:Welcome, liquorhacker...

I think we need pictures before we can be of much more help... Something just doesn't sound right... I'm with Fourway regarding scrapping the whole double boiler idea... Theres good reason why you don't see more members here using that method...

Good luck, and stay safe...

Re: Need help sealing water bath to the still

Posted: Sat Feb 04, 2012 4:08 pm

by liquorhacker

Rachiu,

I appreciate your helping out a newbie like me. This sounds like a simple and elegant solution. So what you are saying is that I could fill the stock pot with sand (see the picture in the other post), and put the still on that. And there will be no scorching!!

Any specific sand or a specific sand ? There was another discussion

http://homedistiller.org/forum/viewtopic.php?f=1&t=2529

where sand use was proposed. Will this slow down the distillation and transfer ?

Rachiu wrote:Fourway wrote:

In a round bottom pot you can apply heat to everything except for the lowest point on the kettle and get a great efficient boil.

Interesting!

3-4 cm sand on the buttom of the pot and there will be no scorching and no need for double boilers and so on.

It's the simplest method which is practiced at the countryside.

Re: Need help sealing water bath to the still

Posted: Sat Feb 04, 2012 4:12 pm

by liquorhacker

Fourway,

I don't feel I must have a water bath. But I do need some technique to avoid scorching.

Unfortunately the bottom of the alembic still is flat (see the images in another post on this thread).

Are you saying if I had a big ring burner say 12" in diameter which applied heat to the sides, rather than the flat bottom there will be no scorching ?

Fourway wrote:Why do you feel you must have a water bath?

You can direct fire positively chunky mash if you are careful.

In a round bottom pot you can apply heat to everything except for the lowest point on the kettle and get a great efficient boil.

Re: Need help sealing water bath to the still

Posted: Sat Feb 04, 2012 4:15 pm

by liquorhacker

Dnderhead,

Thanks for the suggestions. I agree with you about higher pressure and so looking for a safer alternative.

What did you mean by a strap heater ?

Dnderhead wrote:this is not really the place for this but 2 ways that i know work. a false bottom,,or a strap heater.

either way or any way you heat you have to be careful as not to burn if there is suspended trub/particles in the wash/mash.

that is the object of a double boiler or even steam.with water you can only heat to 212f no matter much "fire" you throw

at it. with steam it can be higher but limited by the pressur of the steam.I do not remember exactly but its something like 15-20lb

rise above atmosphere to reach 250f? this takes one hell of a rugged pot,more than any you will fiend in consumer goods.

and then if any thing happens you will be in real hot water not just from explosion but in most places it whould be considered

a hi pressure device and who ever constructs it needs to be certified.

Re: Need help sealing water bath to the still

Posted: Sat Feb 04, 2012 4:39 pm

by Dnderhead

a strap heater is wrapped around the pot,this heats the sides instead of bottom.

there are other ways around but most all is about spreading out the heat so no hot spots or keeping the wash from contacting

the hot spots for extended time.stiring,posably encased in clay? or other?

Re: Need help sealing water bath to the still

Posted: Sun Feb 05, 2012 1:58 am

by Rachiu

I don't think you should use a particular type of sand. The sand dissipates the heat for more even heating.

From what I read (because I haven't seen), the peasants put the sand right in the pot still and then pour the mash over it. I don't know what is happen exactly. Probably the sand prevents the solids to touch the bottom of the pot and thus avoid burning.

What happens when distilling together with sand, I don't know because I don't tried yet, but I know the sand is inert when boiling.

It will not work that way (with water or oil bath). Because your stock pot is too short.

You must understand, the heat in water/steam/oil bath MUST touch ALL OVER the surface of the potstill's boiler! (bottom and walls well above the level of mash). Otherwise you need higher temperatures in bath with risks of burning.

More useful is steam bath because it heats every spot of the boiler but it have a drawback: it have the limit of 100*C. You need higher temperature in bath for bringing the mash to boiling. The difference is around 10-15*C. The steam can be over heated by pressure, by passing it through a fired pipe or by adding salts to the water in greater amounts. 1% table salt in water will rise the boiling point of water with 0,17*C (for each degree celsius you need 58g salt per liter of water). It's a great concentration, so you need very much salt and the water will not exceeds 107*C yet because the solubility of salt in water is limited to 35-40% by mass. But worst thing is a such great concentration of table salt will corrode your metals, don't use it!

Maybe other salts (like CaCl2, MgCl2) have a greater solubility/rising BP properties and less corrosive than common table salt. The salts that dissociates in more than 2 ions rise the BP higher.

A better idea is cooking oil. Oil must be refined, frying intended and fill the gap between walls of the boiler but NOT to the top! Oil expands and can flow over. Let about 5-6 cm to the top of the pot. There must be 3-4cm space between bottoms and 2-3 cm space between walls. You are not allowed to drop any drop of water in oil because it will "sfrrrr!" and can hurt you. Cover the oil somehow. The temperature will never exceed 120*C, so no dangers of smoking, burning or auto ignition that I heard from stupids. Do you know what is the smoke point of cooking refined oils? over 180*C. Palm oil goes to 240*C and so on.

http://en.wikipedia.org/wiki/Smoke_point" onclick="window.open(this.href);return false;" rel="nofollow

It is as well used antifreeze like propylene glycol which is food grade but I didn't find it in my country. It's boiling point is around 190*C.

Another option is a very concentrated sugar syrup. Sugar syrup with 80% sugar will boil at 116*C. Sugar rise the BP of water like salt does but in a lesser extent.

There are some debates too, and you can see my oil bath. I think cooking oil is best. Hope will help!

http://homedistiller.org/forum/viewtopi ... =2&t=26879

http://homedistiller.org/forum/viewtopi ... =2&t=26879

Re: Need help sealing water bath to the still

Posted: Thu Feb 09, 2012 8:23 am

by liquorhacker

Rachiu,

Thanks for your informative post. I am going to give propylene glycol a try. I ordered two gallons on Amazon and it should be coming in today. Hopefully that should resolve the issue.

Rachiu wrote:I don't think you should use a particular type of sand. The sand dissipates the heat for more even heating.

From what I read (because I haven't seen), the peasants put the sand right in the pot still and then pour the mash over it. I don't know what is happen exactly. Probably the sand prevents the solids to touch the bottom of the pot and thus avoid burning.

What happens when distilling together with sand, I don't know because I don't tried yet, but I know the sand is inert when boiling.

It will not work that way (with water or oil bath). Because your stock pot is too short.

You must understand, the heat in water/steam/oil bath MUST touch ALL OVER the surface of the potstill's boiler! (bottom and walls well above the level of mash). Otherwise you need higher temperatures in bath with risks of burning.

More useful is steam bath because it heats every spot of the boiler but it have a drawback: it have the limit of 100*C. You need higher temperature in bath for bringing the mash to boiling. The difference is around 10-15*C. The steam can be over heated by pressure, by passing it through a fired pipe or by adding salts to the water in greater amounts. 1% table salt in water will rise the boiling point of water with 0,17*C (for each degree celsius you need 58g salt per liter of water). It's a great concentration, so you need very much salt and the water will not exceeds 107*C yet because the solubility of salt in water is limited to 35-40% by mass. But worst thing is a such great concentration of table salt will corrode your metals, don't use it!

Maybe other salts (like CaCl2, MgCl2) have a greater solubility/rising BP properties and less corrosive than common table salt. The salts that dissociates in more than 2 ions rise the BP higher.

A better idea is cooking oil. Oil must be refined, frying intended and fill the gap between walls of the boiler but NOT to the top! Oil expands and can flow over. Let about 5-6 cm to the top of the pot. There must be 3-4cm space between bottoms and 2-3 cm space between walls. You are not allowed to drop any drop of water in oil because it will "sfrrrr!" and can hurt you. Cover the oil somehow. The temperature will never exceed 120*C, so no dangers of smoking, burning or auto ignition that I heard from stupids. Do you know what is the smoke point of cooking refined oils? over 180*C. Palm oil goes to 240*C and so on.

http://en.wikipedia.org/wiki/Smoke_point" onclick="window.open(this.href);return false;" rel="nofollow

It is as well used antifreeze like propylene glycol which is food grade but I didn't find it in my country. It's boiling point is around 190*C.

Another option is a very concentrated sugar syrup. Sugar syrup with 80% sugar will boil at 116*C. Sugar rise the BP of water like salt does but in a lesser extent.

There are some debates too, and you can see my oil bath. I think cooking oil is best. Hope will help!

http://homedistiller.org/forum/viewtopi ... =2&t=26879

http://homedistiller.org/forum/viewtopi ... =2&t=26879

Re: Need help sealing water bath to the still

Posted: Tue Feb 14, 2012 11:56 am

by Rachiu

Well done!

Tell us how it works, please.

Re: Need help sealing water bath to the still

Posted: Tue Feb 14, 2012 11:18 pm

by liquorhacker

Rachiu wrote:Well done!

Tell us how it works, please.

I ended up using Oracle's method of propylene glycol bath.

I got a 32 quart stock pot and cut a hole in the lid for the neck of the still

The still sits on an inverted 9" cake pan

Cake pan has holes drilled in the sides

I made a ring of silicone tube (joined together as suggested by Oracle) and put it on the neck of the still

The lid pushes down on the tube and is held down at pot's rim by 12 spring clamps

There is no vapor leak and the thing works beautifully. I need to post some pictures

Re: Need help sealing water bath to the still

Posted: Tue Feb 14, 2012 11:32 pm

by blind drunk

I don't feel I must have a water bath. But I do need some technique to avoid scorching. Unfortunately the bottom of the alembic still is flat ...

The Tuscan hillbillies in the YouTube video line the bottom of their pot with straw mats of some kind. Have a look, it's at the end of the vid after they tip out the pot's content. They are sitting on top of the steaming pomace -

http://www.youtube.com/watch?v=c15CUsw1 ... creen&NR=1" onclick="window.open(this.href);return false;" rel="nofollow

Re: Need help sealing water bath to the still

Posted: Wed Feb 15, 2012 6:40 am

by Rachiu

The straws doesn't carry any flavor into the spirit ?

Re: Need help sealing water bath to the still

Posted: Wed Feb 15, 2012 8:36 am

by Dnderhead

""The straws doesn't carry any flavor into the spirit ?""

i've seen reeds or cat tale fonds used..they were dried first.i thank they also use pom fonds.