Page 1 of 1

VM Help Needed

Posted: Thu Mar 28, 2013 8:59 pm

by hilbilly

I've been running a Boka for neutrals and while it produces good results, I am looking for something better. Fiddling with the needle valve is a PITA. A friend is running a VM and gets better results with no valve hassles so I thought that is what I try. I built the one shown in this pic and did the vinegar run and then a sacrificial alcohol run using some feints. The feints were 60% ABV so I watered them down to about 30%. To my surprise I could not get good results with this setup. I could not get over 91% ABV no matter what I tried. I refluxed at 100% for 30 minutes before slowly taking off spirits and no matter how slow I collected the ABV never went up. I also noticed that the flow was intermittent if I turned it up to 1 1/2 turns of the valve. It would just drip slowly for about 20 seconds then run in a steady stream for 20 seconds and this cycle would just keep repeating.

So the 2 things I was hoping to improve on are both no better or worse with this setup. I must be doing something wrong and need some guidance from the experts here.

First pic is of the whole setup.

Second one showing a close up of the head. This is a 2" column with a 1" take off that is a through pipe, with the bottom half cut away inside the column. See the next pics.

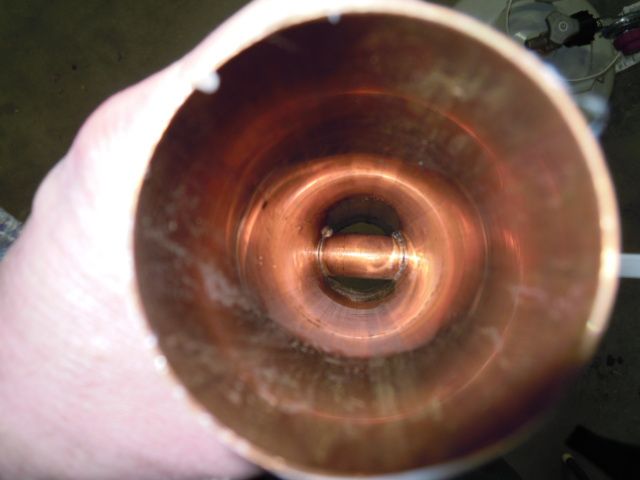

Looking down from the top of the head at the top of the through pipe.

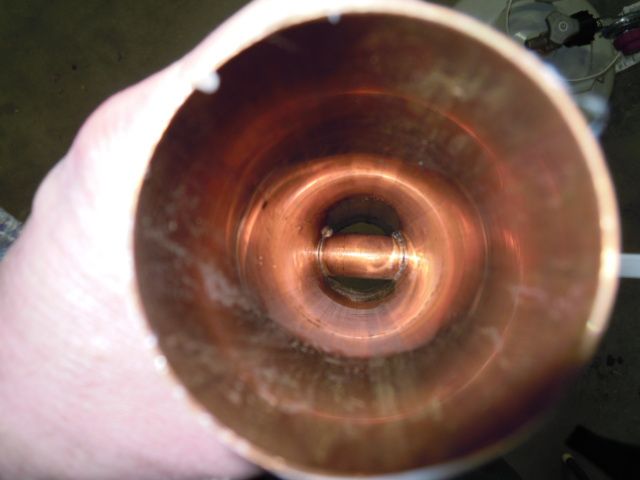

Looking up the head from the bottom. Note the bottom portion of the through pipe has been cut away.

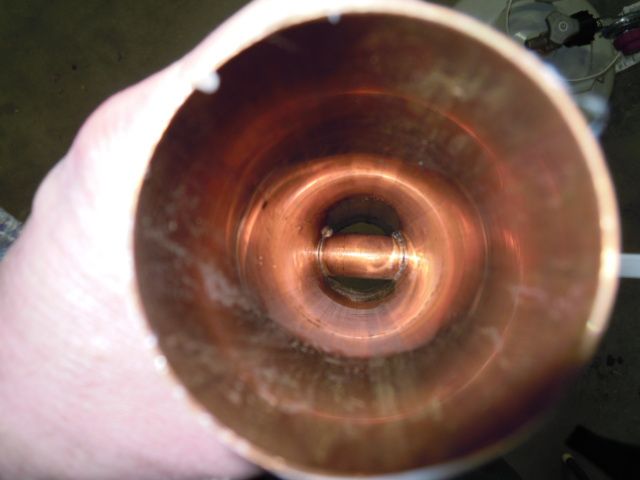

I added a couple of reflux collars to the column and this is a pic of the top one looking down into the column. These are just resting on the top edge of the pipe and held in place by the insertion of the next pipe section.

Anybody got any suggestions as to how can rectify the 2 issues; 1) low ABV and 2) surging discharge.

Re: VM Help Needed

Posted: Fri Mar 29, 2013 10:36 am

by kaziel

What's the temp when u r collecting? I'm not a VM owner but i would take the inside pipe out.

Re: VM Help Needed

Posted: Fri Mar 29, 2013 11:15 am

by hilbilly

Hi Kaziel,

The temp was fluctuating around 169.9*f. It would bounce between 170.1 and 169.5 which suggested there was a problem with equilibrium in the column. So I stopped and gave it time to settle but the same thing kept happening.

The reason I left the 1" pipe through the 2" was twofold; 1) this is one of the connections noted in the Compleat Distiller and 2) I have a friend that uses a VM and he has done the same thing; ie. a 1" through pipe with the bottom 1/2 removed within the 2" column and he gets pure azeotrope from his still.

I've just started another sacrificial alcohol run after adding more insulation to the head and the discharge line to see if that helps. The column is equalizing now and i will soon find out if there is any improvement.

Re: VM Help Needed

Posted: Fri Mar 29, 2013 11:32 am

by rad14701

What size boiler charge are you running for that size of column on a small 1/4 keg...??? Could be the gate valve, cooling surge, column flooding, or the need for more heat input, for starters...

Re: VM Help Needed

Posted: Fri Mar 29, 2013 11:36 am

by kaziel

I've want to start a thread about building VM without external fittings i.e with no "T" fitting and I think now that's possible. Hope that extra isolation will work for you

. So what's the difference between your still and your buddy's still? I'm running immersion heating and got boiler isolated to works great. Keep us (specially me

) posted.

Re: VM Help Needed

Posted: Fri Mar 29, 2013 11:51 am

by hilbilly

Hi Rad,

I've got about 10l to 12l in the boiler ( I need at least 8 to cover the heating elements ). I usually run a 23l charge but this is only cleaning so I thought it would heat up quicker. I heated up with 3000W and as soon as the head temp hit 173* I unplugged one of the elements so then running at 1500W. This is the same way I do spirit runs using the Boka head and this is the same boiler and column I use for the Boka. I did make some minor changes to the column though. Added a couple more scrubbers and 2 reflux collars.

The head temp sort of stabilized at 169.5 after 30 minutes of equalization and then slowly started to creep up and is now at 169.9 after 75 minutes. Seems to be sitting there pretty solid right now. I am taking off at about 4 drips per second and the ABV is about 94* (not temp adjusted). I am going to increase the take off and see what happens.

The discharge rate seems to be constant - not pulsing.

Re: VM Help Needed

Posted: Fri Mar 29, 2013 11:54 am

by rad14701

Without a controller you may not be able to get the heat input set for optimal operation... What may have worked for the LM Bokakob may not work for your VM column... Time will tell the tale... Keep us posted...

Re: VM Help Needed

Posted: Fri Mar 29, 2013 12:12 pm

by hilbilly

Thanks Rad,

I do have a controller, just found I didn't need it for the Boka so figured I give this a go using the same heat settings. Is there a way I can determine the optimum heat settings? Or is it a trial and error thing?

Kaziel,

The main difference between my friends still and mine is that his produces azeotrope and mine does not.

. Honestly though I am not sure I haven't seen a pic of his yet. Will have to see if I can get one. I met him on this forum and he lives on the other side of the country from me. I know he uses more power while he running; 1800W vs my 1500W and he has better insulation for his column. That is the main reason I added more. It seems to help but still not there yet. Maybe I will up the power a bit.

Edit: I bumped the power to 1800W. Unfortunately it was almost the end of the run so I did not get a real sense of what that would do. It did seem to clean up the spirits for a bit but the ABV was no higher. All this effort and no improvement - maybe I'll go back to using the Boka.

Re: VM Help Needed

Posted: Fri Mar 29, 2013 2:05 pm

by hilbilly

Update:

My friend emailed me to let me know that his through pipe has been removed inside of the 2" column and I am thinking this could very well be the cause of the issues I am having. So I will now remove this section of pipe and move the thermometer port over to the take off side. I will report back after the changes are complete and I have had a chance to give the new setup a run. Wish me luck.

Re: VM Help Needed

Posted: Sat Mar 30, 2013 7:06 am

by Maritimer

Well, I'm Hilbilly's friend from the other side of the country. Here is a CAD representation of what I tried to communicate in words, which is not so easy.

The through-pipe is 1 inch ID and the hole is made by drilling two 7/8 inch holes with a hole saw and cutting out the part between them. (I did this on a mill, so I'm only suggesting how to make the holes, not what was really done.) The short end is capped and the long end goes off to the gate valve.

Kaziel,

This technique produces a nice strong joint. My pot still uses the same through-pipe and is able to hold the lyne arm and liebig without adding any extra support.

M

Re: VM Help Needed

Posted: Sat Mar 30, 2013 8:10 am

by Usge

I'm no expert on VM stills, but a couple things just off the top of my head:

1) your "through pipe" is basically pushing the refluxed distillate from the top/coil off to the side walls of the column shading the center. I believe what you want to happen is for it to center.

2)I think most designs of VM I've seen use same diameter take off (tee) and put the therm at the take off on that side (not from the opposite side) so that it's measuring the vapor temp of what you are taking off without being in the way of returning refluxed distillate/liquid. It's then reduced from there.

3) you might not be running enough heat (generally)...which may also explain why your boka was so fiddly. Your VM is determining reflux ratio based on how much you take off as distillate vs how much vapor is refluxed and returned back down the column. How much that is total is determined by your heat. If you are approaching this by running as little heat as possible (ie., higher separation on a "pot" still), you are doing it the wrong way. If you aren't sending enough volume of vapor up the column fast enough...then "any" amount you take off is likely to destabilize the column and it will be hard to form a gradient/fraction in your tube. The fact that your temps kept fluctuating over a range also points to this being part of the issue.

Run a bit more heat. You'll have to find the sweet spot for it. But, for now, just increase the heat you are using moderately. With the valve closed and condensers on, when it starts to boil, you'll see the therm jump. Wait till it settles. Hold it there under full reflux for an hour. If your therm/placement are correct, you should see it settle somewhere just below 173f. You take/bleed the fores off very slowly. The temp will rise as you do. When you get to 173F...stop. And let it sit for another 15 mins or so under full reflux.

The idea here is to maintain that cool pocket, sweet spot..where the purest fractions are at the top right at the takeoff. If you pull it off too fast...it will pull warmer vapor from below up through the column and collapse your gradient. Best analogy I've heard is it's like a high wire walker with a sack of potatoes on each side of the pole. If you take a couple out at a time very slowly he can compensate and remain balanced. But, if you snatch a bunch of them off...he's gunna fall. The key is to watch your therm. If you are taking off too fast it will start to rise. If that happens...close it again and let it sit under full reflux. If it rises even when dripping it off, you either don't have enough alc in your pot to start with..or you need more heat. You mentioned "surging" which might point to you taking off product too fast. It should be a slow, steady....drip....drip.....drip....drip. And your run will more than likely take 10 hours or more. If you are trying to run a fast drip or dribble...you are probably running too fast.

You might have to experiment with the heat to find the right setting. But, once you do...you should be able to drip off steadily at highest proof without unbalancing the column. Even if your therm readings aren't accurate to the proof you are taking off...it's still a response meter to know whats going on inside the column. When you can no longer hold temp ..and/or it just stops producing anymore...you are at tails. You can open the valve, turn the heat up and let her rip (just make sure you aren't venting any vapor past your reflux condenser at top). Those basic instructions work same for your boka as well. If you don't run enough heat...and/or are taking off product too fast...it will be finicky as hell and require constant adjustments.

I've heard as well that the VM, once set properly, requires little adjustment and will run squeezing off neutral up and too it hits tails where it will just "stop". But, not having run one, I can't confirm this or not. But, I would guess that might be something to shoot for when knowing if you are doing it right or not.

Re: VM Help Needed

Posted: Sat Mar 30, 2013 9:31 am

by Maritimer

Usge, you are right about how easy the VM is to run once you have found the sweet spot. I take off tasteless azeotrope at the rate of a little over one liter per hour, which, coming out of the parrot, is a steady stream. No adjustment at all is required.

The mythical automatic stopping when you reach the tails is only partially true; the tails will come out after the hearts at a very decreased flow rate. I haven't gone further than seeing the decreased flow (and increased vapour temperature) because the tails are so vile that I can't imagine re-distilling them. Maybe flow would cease eventually.

For anyone whose interest is good neutrals, I would recommend the VM for its ease of use and high quality output.

M

Re: VM Help Needed

Posted: Sat Mar 30, 2013 9:47 am

by hilbilly

Last night I decided to try and remove the interior section of the 1" through pipe but could not figure out how to do it with the tools I had. So I took apart the head and made a new one with a butt joint.

This pic shows the interior, which has not been cleaned yet.

and here is a close up of the soldering at the joint. Not pretty but I was trying to build up the solder and found it a little difficult to do. I think this might be strong enough, as I grabbed the head in one hand and rested the bend on my belly, while pulling the end of the downpipe and the top of the head towards me at the same time. Essentially trying to get the joint to break. Even with quite a bit of pressure it did not bend, crack or give any indication of potential failure.

Maritimer:

Thanks for the cad drawing - that clearly shows what you did and I'm sure that would be a rock solid structure.

Usge:

The Compleat Distiller shows a VM design that includes a 1" x 1" x 1" tee between the top of the column and the bottom of the head. From what I have read in other threads here and info in the Compleat Distiller the take off size is not important but the minimum size that the vapour sees on the discharge size is. There seems to be some disagreement about this issue. So I decided to go with a design that has proven to produce what I am after; pure azeotrope at 1l per minute. Maritimers setup does this so I figured I would follow his design, which has a 1" takeoff from a 2" column. Once I get this new head finished (I still need to add the therm port on the take off line) then I can try running with more heat. Maritimer pointed out that my therm placement may have had something to do with the fluctuating temps I was getting.

The fiddly part of the Boka is the damn brass needle valve. The settings change as the valve heats up and if you are not watching it like a hawk the discharge flow will suddenly increase drastically. This can and likely would screw up the column equilibrium if it is not caught as it happens. It usually takes several adjustments to get the final setting. I also found that if I lift up on the valve stem or push down on it the flow will change. The valve is also stiff to turn when it is cold and very loose once it heats up. Probably should have gone with a stainless valve. I think I have the Boka tuned in but maybe not. Once I start taking off the hearts the temp usually sits rock solid at 169.2 while I take off 1l per hour and when I hit the tails the temp will bump up 0.2* then start to climb. I am at about 2700' elevation so boiling temps are lower here. Maybe after I move the therm on the VM I will get more constant temp readings too. Time will tell.

Thanks everyone for the help and suggestions. I will keep you posted on the results. But that will have to wait for a bit, since I am going away for a while (no I didn't get caught and I'm not going to the Big House, it's a short vacation)

Re: VM Help Needed

Posted: Sat Mar 30, 2013 10:01 am

by kaziel

I've got stainless valve on my Boka but output is like 230ml/h maybe a bit more. I like that setup even as slow as it is

I've made it from scrap so it wasn't that expensive, but I'm thinking about something faster like 2" VM/LM Boka combo. In some post of Samhogon I've found that setup with 3 separating collars he can pull 1.8L/h @ 92% i think. I definitely must give "The Compleat Distiller" a try

Re: VM Help Needed

Posted: Sat Mar 30, 2013 11:37 am

by hilbilly

Kaziel,

I am pulling 1l an hour from my Boka at 93% to 95% but normally around/slightly above 94%. For me it is more about getting pure azeotrope to see what that is like. I still get some smell and taste from in my spirits and I would like to see if that disappears at 95.6%. Also I want the ease of operation using the VM - no more fiddling with a crappy needle valve (I know that can be solved with a SS valve), but I also enjoy the building part.

Maybe an LM / VM is the best of both worlds and maybe I will end up there. I guess I am doing it one step at a time. One concern I have with the VM is the loss of the ability to collect tails. I currently have 23l of feints with about 1/2 of that being tails. That has been collected from my Boka and I am hoping it will produce some decent hearts - question for another thread.

Re: VM Help Needed

Posted: Sat Mar 30, 2013 11:53 am

by kaziel

I don't have a lot or runs under my belt and I'm working on small column 1.25" i think I can go with 0.3l/h on a spirit run but that's for me to try. For sure i will go with LM/VM combo but the q is 2 or 3 inch. I can buy 96% (that what's on a label) in store and some time ago I've used to that spirit was rectified twice and stuff that I'm pulling from my Boka is litter more burning on throat when diluted but it's also lightly sweeter, I like it that way.

Re: VM Help Needed

Posted: Sat Mar 30, 2013 1:05 pm

by Usge

hilbilly wrote:

Usge:

The Compleat Distiller shows a VM design that includes a 1" x 1" x 1" tee between the top of the column and the bottom of the head.

Just like anything that was written some time ago, things change over time as consensus forms around trial and error. But, as I recall, the important thing that made a difference was...that your tee be even. Ie., that the initial takeoff from the column be the same size/diameter as the column. So, your tee should be even all the way round (x by x by x). Normally, on VM builds I recall using 2" column....that means a 2" x 2" x 2" tee. If you've reduced your column to 1" at that point, then 1 x 1 x 1 is fine. Most of them I've seen also use a gate valve as well.

As well, most of them did not run "streams". You had to drip them off to get highest proof. You "can" run them faster at slightly lower proof and many of them do...as a trade off and seem to be happy with it. That's very impressive to be getting 1liter per hour if you are pulling 96+% Good job

Re: VM Help Needed

Posted: Sat Mar 30, 2013 1:57 pm

by Maritimer

I'm wondering if my output is so good because of the excessive insulation that surrounds my still. Here is a picture of it from another thread:

http://homedistiller.org/forum/viewtopi ... 0#p7023905 . The black insulation was only for the RR experiment; normally only the blue insulation is used. This is high density Styrofoam, 2 inches thick at the sides and 6 inches in the back and 4 inches in front. It is rated R10 at 2 inches. Even the gate valve is insulated. The Styrofoam also holds the still plumb because it is held in position by guides on the wall.

Has anyone else used excessive insulation?

M

Re: VM Help Needed

Posted: Sat Mar 30, 2013 2:03 pm

by maheel

i dont believe the cross pipe is making any difference to the offtake %

i have been building them the same way and easily get +95% when wanted using a full bore 1" SS ball valve

if using that but joint i would support it with a bit of tube angled from near the valve to the main column at 45" to support all the weight hanging off it

Re: VM Help Needed

Posted: Sat Mar 30, 2013 2:06 pm

by Usge

Very well could be. I can honestly say that in the 5+ years I've been around here I've never seen one insulated in that particular manner

.

You might find this an interesting read:

http://homedistiller.org/forum/viewtopi ... =1&t=11396

Re: VM Help Needed

Posted: Sat Mar 30, 2013 2:45 pm

by hilbilly

Usge wrote:hilbilly wrote:

Usge:

The Compleat Distiller shows a VM design that includes a 1" x 1" x 1" tee between the top of the column and the bottom of the head.

Just like anything that was written some time ago, things change over time as consensus forms around trial and error. But, as I recall, the important thing that made a difference was...that your tee be even. Ie., that the initial takeoff from the column be the same size/diameter as the column. So, your tee should be even all the way round (x by x by x). Normally, on VM builds I recall using 2" column....that means a 2" x 2" x 2" tee. If you've reduced your column to 1" at that point, then 1 x 1 x 1 is fine. Most of them I've seen also use a gate valve as well.

As well, most of them did not run "streams". You had to drip them off to get highest proof. You "can" run them faster at slightly lower proof and many of them do...as a trade off and seem to be happy with it. That's very impressive to be getting 1liter per hour if you are pulling 96+% Good job

I'm only getting 93% to 95% but usually +94% when taking off 1l per hour. My first runs were painfully slower at around 350ml / hour and the ABV was no higher. So I kept upping the take off rate until I seen the temps start to vary or the ABV fall and eventually figured out that my setup could run at 1l per hr and still get good results.

My take off does have a 1" gate valve and that works much nicer than the brass needle valve on the Boka.

Maritimer;

That is a heck of a lot of insulation and maybe it

is the reason your still works so well. I bet there is no heat loss with that setup.

In any case your still has a 1" take off and produces what I am seeking, so I should to be able to achieve the same with mine. Just gonna have to figure out what it will take.

Maheel;

I will likely add a support pipe since it is better to be safe than sorry. I might wait until I confirm that I will get the desired results. Just gonna take some time and that's fine.

Re: VM Help Needed

Posted: Sat Mar 30, 2013 9:01 pm

by Usge

Hillbilly, 94%+ at 1lt per hour is pretty darn good if you ask me. As I said before...there are many before you who found that a worthy trade off vs the take off speed (ie., the distillate didn't suffer that much...but the run times were shortened immensely). That of course also depends on your ferments as well.

The fact that running slower take off didn't bring any higher % shows there's either something missing somewhere with your build, or in how you are running it, or there's something wrong with your hydrometer or reading. Are you sure you are reading your hydrometer right? (ie., is it off?) Did you adjust for temp when you took your hydrometer readings?

Re: VM Help Needed

Posted: Sun Mar 31, 2013 7:16 am

by hilbilly

Usge wrote:Hillbilly, 94%+ at 1lt per hour is pretty darn good if you ask me. As I said before...there are many before you who found that a worthy trade off vs the take off speed (ie., the distillate didn't suffer that much...but the run times were shortened immensely). That of course also depends on your ferments as well.

The fact that running slower take off didn't bring any higher % shows there's either something missing somewhere with your build, or in how you are running it, or there's something wrong with your hydrometer or reading. Are you sure you are reading your hydrometer right? (ie., is it off?) Did you adjust for temp when you took your hydrometer readings?

The alcoholmeter readings vary slightly throughout the run, depending on where the cooling water temp is. Just after a fill of fresh cold water the readings will be slightly lower than just before the water is changed and is therefore hotter. Maybe 1% max difference, but usually less. I don't normally adjust for temps when I am collecting and often get readings of 96% (which I know is not correct due to temps). I do correct for temps when I water it down to 40%.

The alcoholmeter readings are a relative thing though during a run, if only used for comparison purposes, ie to see if they go up with a slower take off rate. My short experience indicates that they do not change when I slow down the take off rate. I checked my first run documents and note that something strange happened when I slowed down the take off rate. The ABV went down about 0.5% and this is when I was still taking it off very slowly (around 350ml per hour). I was getting unadjusted readings of just under 95% and I wanted to see if I could get the ABV higher. I even tried stopping take off and going to 100% reflux for 15 minutes. But the ABV did not go up. So like many others, I said to heck with the slow take off rate and just kept upping the take off until I got close to max without the vapor temp changing.

If there is something wrong with my build or operating procedure I would love to find out what it is. If it is the still then I would alter it to make it better. If it is the way I am running I would try a different method to see if I can get higher ABV. If I can achieve this then i know I am doing everything right and then decide if I want to sacrifice higher ABV (and maybe quality) for a higher take off rate.

Re: VM Help Needed

Posted: Sun Mar 31, 2013 7:44 am

by rad14701

There's no real need to chase after a seemingly magical number... Just determine what take of rate and strength provides the spirits you like best... It may be 95%, 93%, or 90%...

I like anything from crisp clean 95% right on down to under 60%, blended, depending on how much hint of flavor I'm after... And it doesn't matter whether I'm running in full reflux, hybrid mode, or pot stilling... Sometimes I even surprise myself, like last night when I ran off some puffed red wheat sugarhead in hybrid mode and ended up with some very light tasting 116 proof that just gives a slight mouth feel aftertaste... And that's my personal preference for drinking strength in mixed drinks... I had one with water and it was very impressive... It's not all about shooting for high numbers...

Re: VM Help Needed

Posted: Mon Apr 01, 2013 12:43 am

by lampshade

Usge wrote:

Just like anything that was written some time ago, things change over time as consensus forms around trial and error. But, as I recall, the important thing that made a difference was...that your tee be even. Ie., that the initial takeoff from the column be the same size/diameter as the column. So, your tee should be even all the way round (x by x by x). Normally, on VM builds I recall using 2" column....that means a 2" x 2" x 2" tee. If you've reduced your column to 1" at that point, then 1 x 1 x 1 is fine. Most of them I've seen also use a gate valve as well.

In the above, Usge says its best to use an even tee (x by x by x). Why is that best?

Re: VM Help Needed

Posted: Mon Apr 01, 2013 5:23 am

by Maritimer

From my experience, it doesn't matter. I suspect it is one of those ideas that become superstitious, blindly accepted because it is repeated as true.

M

Re: VM Help Needed

Posted: Mon Apr 01, 2013 6:31 am

by Usge

It was something that came up and went through the discussions about VM when everybody was hot on using them years ago. Must have been a few years back. But, as I recall it, it wasn't just done for superstitious reasons. Several users did some testing and posted data of the results and came to the conclusion for whatever reason that it was better that way. I wish I knew more about it and could explain it better But, alas, I'm only remembering that there was a reason it became the standard way people made them after that point. Probably have to do a lot of digging through older material....ie. even the archived stuff.

Here's an answer for you from an older post.

Re: VM size of tee

Postby eternalfrost » Mon Apr 20, 2009 10:19 am

you want even sized branches so that you can get effective vapor splitting.

if you have a 2X2X1/2 T instead of evenly sized for example, only a small portion of vapor can be removed from the column and you will be stuck with a extremely high reflux ratio and slow output.

Here's another older thread with some test/run data in it comparing various take off and valve sizes and reductions to measure the impact it has on the reflux ratio.

http://homedistiller.org/forum/viewtopi ... =1&t=11396

Certainly can't argue with a liter an hour at azeotrope for an output rate. There is more in archive...I think the google HD search picks it up. Mimime would be a good user to look through posts. He used VM's extensively and I believe he was in on some of the earlier testing I was referring to. You should be able to dig up run data and lots of math between him and eternalfrost. Now days, it seems most people who use VM try to find ways to combo the head with LM. So, the parameters are a bit different. Sorry guys, that's about as close to an answer as I can find for now as to why it changed and the reason for it.