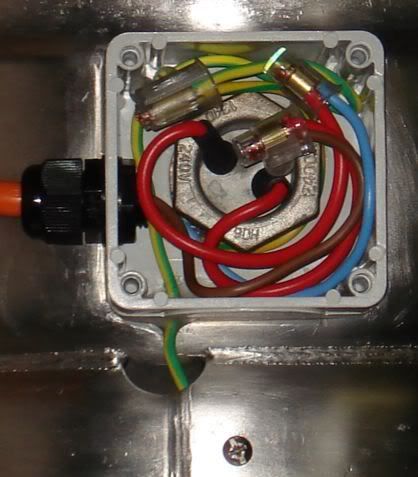

The boiler:

Some fittings:

I'm still yet to get my copper bits. The only reason I haven't got them yet is I'm still not sure what kind of still I want to build to suit my requirements.

Moderator: Site Moderator

Well... what do ya plan on doin'? We can help ya in that department.Froggy wrote:I'm still yet to get my copper bits. The only reason I haven't got them yet is I'm still not sure what kind of still I want to build to suit my requirements.

Hi mate,BW Redneck wrote:Well... what do ya plan on doin'? We can help ya in that department.Froggy wrote:I'm still yet to get my copper bits. The only reason I haven't got them yet is I'm still not sure what kind of still I want to build to suit my requirements.

Many have noticed that they start using their pot head more than their reflux after the novelty wears off. Most only keep them around for fixing mistakes.

If you are just using the reflux to clean up mistakes, then build a bok inline or some other LM design.

However, if you're giving vodka out to people as gifts, making cordials for parties, or if flavored spirit ingredients are rare in your area (some can't get basic feedmill items), then a Vapor management design is going to be the most reliable, easiest to use, and most durable head you'll ever build.

It's like deciding on an AL or SS boiler, are you only going to use this thing once a month and use it gently, or are you going to use it daily and beat the sh*t out of it?

(Don't want to restart that debate again)

Thanks mate,punkin wrote:You're doing the right thing. Hold your bits in the shed, keep an eye out for more bits, and keep reading the forums here.

Go back through all the old posts, pages and pages of em. Read the lot.

The differences will come clear to you, and you will have no trouble deciding not only what you want, but excactly how you want it.

Get the design completely clear in your head, then draw it (good idea to post it up here) using all your joining components right down to your output height ect.

ThenGetTheGrinderOutPunkin

Sorry mate, It was a bit of a poor photo. They are just 2 inch threaded fittings screwed together. Here is another photo of them apart:Safegyde wrote:Froggy, In the pic with your fittings, what is that piece on the far left? Is that a built in filter?

Where did you come across those fittings?

Hi mate,HookLine wrote:Most big electrical trade suppliers will stock them. 'Stokes' is the main manufacturer/importer of water heating elements in Australia I think. Their catalogue is online.

Also check out these guys.

Get a low density, Incoloy 825 coated element, they last forever and are the same price as tin coated. If they don't have 825 then get the 800 coated. Incoloy is a type of stainless with very high corrosion resistance.

My elements has a 1" BSP thread mount on it, which means it can be mounted externally, so you don't need access to the inside of the boiler.

Also, I don't know exactly what your plans are for mounting the column to the boiler, but you might want to consider using a 50-40 BSP reducer, instead of the straight 50-50 BSP coupling you go in the photo. The 40 mm end sits straight on top of the keg opening, and the reducer section also holds a mesh retainer. Something like this:

This was going to be a question I was going to ask later on when I'm about to build the column. But since we're on the subject I might as well clear it up now.HookLine wrote:One more suggestion: Depending on your set up, consider using a female fitting on the end of your column. It does mean an extra male-male fitting between the female on the column and the female on the boiler, but it also means you don't have an exposed thread on the end of your column.

That is one thing I would change if I did mine again.

Do you have any pictures of your new still?wineo wrote:I had a offset head reflux that I built when I first started,but built a potstill column and ended up using it all the time.I desided to use the copper from my offset head column to build a new column that will run faster,but still get 80-90%.Well,its almost together and I made a 36 inch tall,2 inch column that I will pack with SS scrubbers except for the last 6 inches at the top.Im using a 2 inch cap with a 1/2 fitting coming out the top to connect to my condencer.It has a piece of 1/2 inch extending down into the column 4 inches.I have a dial thermometer mounted at 5 inches down so its at the vapor takeoff point.Im running a 4 ft leibeg condencer at a 45% angle downward.The leibeg is made with 1/2 inch copper with a 3/4 inch jacket.

I made this to run sugar washes and vodka.I dont know what kind of % it will run yet,but should run as fast as my potstill with a higher proof.

The old one worked fine,and would easily run 95%,but I didnt like the long run times,and dont want to strip all the flavors out so we will see.

Im waiting on another triclamp fitting for the column so I can test it out.

I have 22 gallons of sugar wash waiting.

If you have a male fitting on the bottom of the column it has an exposed thread, and so can be damaged fairly easily during handling or storage of the long and unwieldy column. I have an end cap that screws over the male thread when storing the column, but it is only a partial solution.Froggy wrote:This was going to be a question I was going to ask later on when I'm about to build the column. But since we're on the subject I might as well clear it up now.HookLine wrote:One more suggestion: Depending on your set up, consider using a female fitting on the end of your column. It does mean an extra male-male fitting between the female on the column and the female on the boiler, but it also means you don't have an exposed thread on the end of your column.

That is one thing I would change if I did mine again.

What's the idea of having the female fitting on the end of the column? I was thinking that having a male fitting on the end of the column would be better so that any liquid returning to the boiler wouldn't foul on the join.

Froggy, the reason behind the female on the end of the column is when you break it down for cleaning, there is alot less chance of bunging up the threads on the female fitting than there is on a male fitting, like hitting the side of the sink or so on.Froggy wrote:This was going to be a question I was going to ask later on when I'm about to build the column. But since we're on the subject I might as well clear it up now.HookLine wrote:One more suggestion: Depending on your set up, consider using a female fitting on the end of your column. It does mean an extra male-male fitting between the female on the column and the female on the boiler, but it also means you don't have an exposed thread on the end of your column.

That is one thing I would change if I did mine again.

What's the idea of having the female fitting on the end of the column? I was thinking that having a male fitting on the end of the column would be better so that any liquid returning to the boiler wouldn't foul on the join.

Correct, it now has a (locking) ball valve permanently screwed into it. Get the locking kind, then there is no danger of you accidentally bumping it and opening the valve during a run.Froggy wrote:That looks like a good idea. Is that another fitting on the opposite side of the keg? Used for a drain?