Page 1 of 1

Can i use this in my cooling bucket?

Posted: Thu Dec 27, 2007 3:01 am

by Grid

I have a pot still with copper pipe coming out the metal lid and need to go to the cooling bucket.

This product is at my local scrap supplier at $10 each (2mt long)

http://paramountbrowns.ihub.com.au/Desk ... ntbrownsau" onclick="window.open(this.href);return false;" rel="nofollow

i have done a google search for the meaning of Braided stainless steel hose and doesnt say anything about plastic/rubber or any other material that the alcohol could eat into and muck up the taste.

So could it be used?

Grid.

Posted: Thu Dec 27, 2007 3:08 am

by absinthe

these hoses have a plastic liner inside the braid... i would say no dont use it in the vapour path...

but if you pull the plastic out you have a nice mesh hose you can use in the bottom of a mush tun to filter out the grains.

Posted: Thu Dec 27, 2007 3:14 am

by bourbonbob

you would be best to use copper for your coil, you could buy 3/4" annealed copper, it would be have the ability to remove unwanted sulfides, might be a bit more expensive but the end result will be rewarding.

re pot still

Posted: Thu Dec 27, 2007 3:38 am

by Grid

Thanks for the info..I have brought some 3/4 copper pipe (3mt long) and tryed to bend it into shape with a pipe bender but it just doesnt want to bend on a nice corner or twist for the coil.it just kinks in one spot and looks crap then i have to straighten it out again .

Now i have 2 pieces (1 about 2mt and 1 at 1mt)as when i tryed it bend it it cracked and had to cut it.

I thought the above Braided stainless steel hose would to the job easier.

Would i be right in saying if i brought 3/8 or 1/4 copper pipe it will be easier to get the shape i need(coil/bends..etc.)

Grid.

Posted: Thu Dec 27, 2007 3:44 am

by arkansas

Grid, pipe and tubing are much different, the tubing has been annealed and there for softened so that it will bend in the shape you are looking for. Take a trip down to the local hard ware store and ask for copper tubing insteed of pipe. It will come in a roll, not a straight stick. Just my suggustion.

Posted: Thu Dec 27, 2007 3:55 am

by Grid

tubing. yes thats what i got the first time and it was rolled in a circle the size of a truck steering wheel and i needed to make it a smaller coil for the water cooler,and thats where i did the damage first time.

Grid.

Posted: Thu Dec 27, 2007 4:22 am

by goose eye

these boys i no aint never done nun that small but what you rollin round is you rollin air or you rollin it out an pack it with sand. i read where some folks on here use salt but sand is free in the warshs in the branch. sure one of these smart folks like tater or pint or such got pictures on how ta do it if not you ask em nice they mite come up with some.

you cant be getin in no hurry an if you lookin the easy way go to the likker store

so im tole

Posted: Thu Dec 27, 2007 4:33 am

by Ricky

if you cant roll a coil then maybe you need to try a liebig(water jacket).

i know you will then have to buy a pump but they work nicely.

Posted: Thu Dec 27, 2007 5:55 am

by Grayson_Stewart

Search my posts. There is a detailed description with pics on how to roll a double helix condensor from copper tubing using salt to fill the condensor to prevent collapsing. Seems like I posted it a year or two ago.

Sand works as well as salt, will have to use a little patience and energy to pack either one in the tubing, but salt will dissolve and wash out where you will have to work harder to get the sand out.

Posted: Thu Dec 27, 2007 2:32 pm

by Old_Blue

Grid, How big is the diameter of you bucket? I've saw it where you can hold the bottom end and pull up the top end to the height you need and the diameter of the coil will decrease as you go. If it will go in the bucket then solider a brace down each side to keep some separation in the coils. Might take two people, just do it sllloooowwww and careful.

Posted: Thu Dec 27, 2007 7:11 pm

by Grid

Okay i think i have just solved my problem with keeping it cool.

Got a 17lt storage crate and put 1 hole each end with water proof rubber washers and a tap.run the copper pipe through the middle and fill it with cooling water(like a big bath with 2 holes).

No bends ,no kinks,no soldering.

Just comes straight out the top of my pot still,bend to a angle then into cooling water bath (about 1.5mt away from pot still)

Just like the liebig(water jacket) system but more water for me to change and keep cool.(could also ice ice)

I am waiting for the silicone to dry and my wash to finish then will try it.

Shouldn't leak as i have used lots of silicone to seal the bath at each end and there shouldn't be to much water pressure up against the rubber washer seals.

I like and know how the copper coil is suppose to cool the liquid and that would be the ideal way but here in oz the 3mt of 3/4 copper was $38.00.

The hardware shop didn't have smaller sizes in stock and i thought 3/4 would be a okay size and might bend easy with a bit of time and patience(that i am short on).

But my plans and design didn't work out like i wanted to but i can look to improve or change it later with more help from you guys.

Thanks again

Will keep reading and reading and reading.

Grid.

Posted: Fri Dec 28, 2007 11:23 am

by punkin

Just make sure you still have enough downward angle for the distilate to run. Would say that a 17 litre container will give you the shits real quick trying to keep it cool. Unless you can rig running water to it, you'll be running yourself.

Old fella i saw once had a big 200 litre plastic olive drum with a bit of 3/4 running vertically down through it for his grappa still, said it worked ok....

I use a wheelie bin.

The coils are just to make the pipe longer and expose more surface area to the cooling liquid.

I think you have to reassess the scope of things...

Posted: Fri Dec 28, 2007 7:13 pm

by Grid

Thanks for the info punkin.yes the pipe has a nice downward angle an is on a downward angle through the cooler.

I think the cooler is more than 17lt as i have filler it with water today and it took 2 10lt buckets.

I see on some other post that they are saying about using homebrew beer as there wash? Am i reading this right.?

I have some homebrew that i made and the flavor wasn't what i expected.

Can it be used and is there any other ingredient that needs to be add.

Also can you tell me what stripping is?

Grid

Posted: Fri Dec 28, 2007 9:41 pm

by CoopsOz

Stripping = Doing a hard and fast distillation without making any cuts, different people collect to different points. When I do a strip run I collect down to 1/3 the initial volume of the wash. Once you have got enough strip runs to fill the boiler you the do a spirit run.

Posted: Fri Dec 28, 2007 9:42 pm

by cannon.co.tn

you can certainly use homebrew. Afterall; malt whiskey is just distilled beer. However; it has been noted by those who have tried this that the beer needs to be unhopped. Apparently some of the bitterness and flavor of hops will carry over, reported as not being pleasant. I haven't tried with hopped beer myself.

Posted: Sat Dec 29, 2007 5:50 am

by Old_Blue

The hops will carry over but the beer can be used as a practice run after a water/leak test on your new build.

My beer failure

Posted: Sat Dec 29, 2007 11:09 pm

by Grid

I have tried my homebrew today as i am waiting for my wash to finish bubbling,put about 6lt of homebrew in my 11lt pot and had it up to about 78c (sometimes the temp would rise to about 85-87c but adjusted the temp but after about 2hr was no liquid.

Now i have my suspicions about my temp gauge as at 78-80c it was not bubbling at all so i put a bit more heat in it (up to 100c) until it started bubbling and just kept checking it,so i finally got some liquid after more heat.

If the temp gauge is wrong ill throw it out.

But the liquid that came out was only about 200ml very clear smelt a bit off but after a taste had no alcohol bite to it at all.

The homebrew was a can type homebrew(that may have been my problem????) like these

http://www.coopers.com.au/homebrew/hbre ... d=1&id=109" onclick="window.open(this.href);return false;" rel="nofollow

does that make any difference?.

I had it running from start to finish for 7hrs(1 1/2hs was for heating it)

Can anyone tell me what i have done wrong.

Grid.

Posted: Sun Dec 30, 2007 3:41 am

by arkansas

Only two things I can think of atm is a possible leak or the mash didn't have any alcohol in it.

Posted: Sun Dec 30, 2007 6:41 am

by Old_Blue

Grid, did you check your start and finish gravities of the beer so you have an idea of the % alcohol in it? A 3 or 4 % beer is going to start boiling at a higher temp than plain alcohol. There are some charts on the main site that shows what you can expect. Do a quick check with your thermometer in some boiling water before you throw it away. If its close then you can eliminate that as the problem and explore other possibilities like leaks and such.

Posted: Sun Dec 30, 2007 8:04 am

by Usge

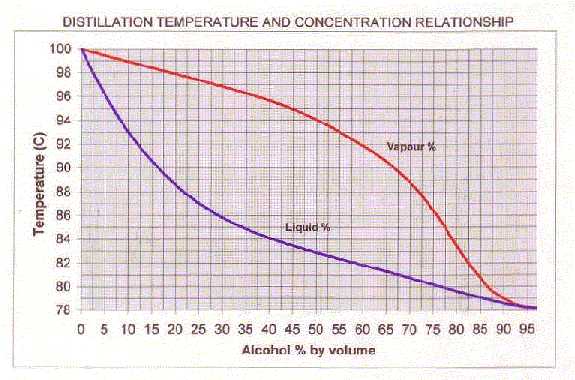

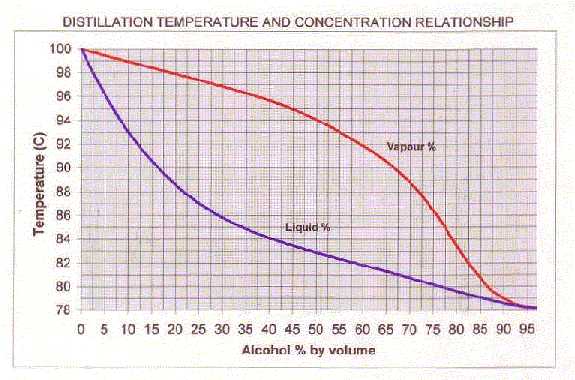

On main site, Theory section/Alc vs Temp

Posted: Sun Dec 30, 2007 8:07 am

by Usge

According to the chart and assuming a 3-4% beer, the vapor would start to come off at around 97C and would be around 30% abv.

Posted: Sun Dec 30, 2007 9:04 am

by Old_Blue

Grid, as you can see from what USGE is pointing out the alcohol/water mixture is not going to start boiling until it is almost to the boiling point of water assuming a 3-4% abv. It will be almost impossible to separate with a pot at this concentration because a lot of water vapor is going to be pushed out with the alcohol. It's not a clean cut off between the two but an overlap of all the liquids.

Using the middle of our assumptions, 11lts of 3.5% is only going to give you 385ml of total alcohol (fores, heads, middle, tails) so your results may not be as far off as you think. I think when you run again with a higher % wash you will see results closer to what you were expecting. Someone will correct my math if its not correct.

Read some more and think about it a while, it will come to you.

At least you got to test your rig

.

Posted: Sun Dec 30, 2007 11:17 am

by Usge

I have found the above chart to be generally accurate description of how a given wash. low-wines, etc., of a starting abv will respond in my pot still. My personal observance using using it and cross checking with it was that it was pretty accurate to my findings save the higher starting abv/lower temp readings where there was some increasing levels of variance with the chart from my experience. (noticable from about 50% on)

As to the 3-4% wash....just strip it to a higher abv low-wines and save up enough of them to charge your still for a 2nd run. Then, do the cuts.

Posted: Sun Dec 30, 2007 2:41 pm

by Grid

Thanks for the reply s everyone,I think you maybe be right Old_blue.maybe the beer was a lower alcohol %.I normally check the start and finish gravity's of my beers but i forgot with this one

97c that is close to the temp i had it at,and i was concerned that i would boil it to much and have a syrup blob in my pot(didn't know what to expect....newbie)

It is only a new digital thermometer so i hope it is right as it wasn't a cheapo one,but i will check it in some boiling water first.

I will have a double check for leaks but i don't think there is any but wont harm in checking.

I think it might have been me being to concerned about the high temp and what might happen and maybe turned it down to much and lost the flow

I am waiting for a basic sugar wash to finish in plastic fermenter

(plastic...... thats a touchy word on these forums) then i will give that a go...fingers crossed all goes well.

Thanks again for the help.

Grid.

Posted: Sun Dec 30, 2007 2:48 pm

by CoopsOz

As long as the word "plastic" only ever precedes the word "fermenter" all will be good.

Posted: Tue Jan 01, 2008 7:47 pm

by Grid

Yesterday my wash was finished (after about 7 days in my fermenter)(checked it with a hydrometer and was all okay) so i started to boil the wash.

About 3 hrs later i got about 400 ml of off smelling water ....AGAIN

I have checked for leaks under pressure (small tap at the end) and none there,so it isn't sucking cooling water through the connections.

I have 1 small bit of stainless steel in the copper pipe above the pot before the bend to the cooling water,my way of thinking is that i am getting to much water vapor through the pipe and no alcohol.do i need more stainless steel in the pipe.?

Today i did 90 degree modification to the copper pipe at the first bend coming off the pot,(it had a 90degree bend and i got some 90 degree threaded elbow sleeves).Makes it look and hope work better.

I know i will get a small amount of liquid as i am only using a 11.5 lt pot with about 8lt of wash in it.but the off smell and no alcohol.?

What am i doing wrong?

Grid

Posted: Tue Jan 01, 2008 7:59 pm

by CoopsOz

Grid, I went through your old posts but couldn't find a picture of your setup....could you post one? Are you giving it to much power and the vapour is spewing straight out the top?

Posted: Tue Jan 01, 2008 8:10 pm

by Grid

Thanks CoopOz,I was just reading some text that i got from another site and i think you are right...my temp is to high.I must be boiling the water out of it and no alcohol.

No i haven't got any pics as yet but that is on my to do list very soon.(that way other people can share there views of what i have done)(good or bad).

will try again soon.

Thanks for the help.

Grid.