Page 1 of 1

A Custom Still - Let's break it down...

Posted: Tue Oct 28, 2008 5:22 pm

by Socrates

As a rum drinker I recently became aware of a very limited production custom alambic copper still made in France by a gentleman named Jean-Louis Stupfler. His stills are promoted as the "Cadillac" of small commercial stills. Two boutique commercial distillers in California use it, one for rum (and grappa, brandy and gin) and the other for gin. Both proclaim their product is made using this "wonderful pot still" - the gin producer claims his product is made in a single pass (distillation).

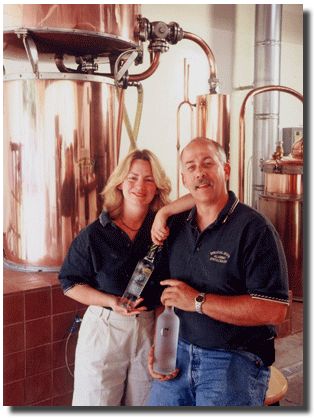

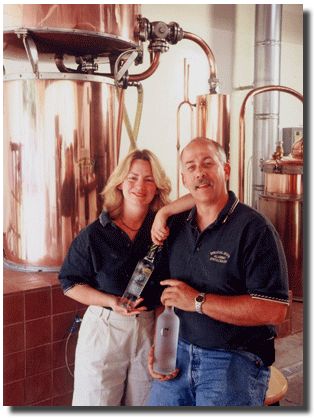

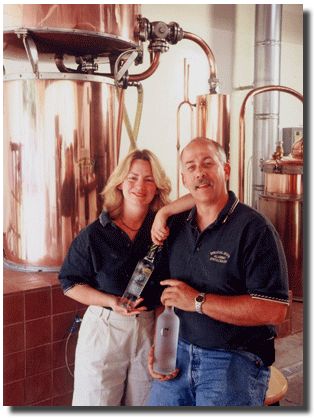

Here's a couple pics of the still...

It should be apparent this is no simple alambic pot still. I think the pics are good enough for the experienced distillers here to break down the process. It sure starts in a pot, but then....?

How do you think this one works?

Re: A Custom Still - Let's break it down...

Posted: Tue Oct 28, 2008 7:20 pm

by Socrates

I did write one of the distillers and asked these questions:

Noting your website pic of the still, it appears the rum begins its journey in what appears to be a simple, jacketed pot still, then passes through three structures, which seem to include some type of reflux process.

Can you describe the process from beginning to end?

Is the rum produced in a single distillation?

Is there a reflux process? Does it use vapor management, liquid management or temperature management?

Do you use the still for all your different products?

Here's what he answered:

As for your questions... its really a matter of symantics whether or not you consider it single pass or double distilled in a single pass. Basically, there is a 2nd "inline" distillation that occurs, but it does not have its own heat source, so i dont think you can actually call it a "pass", or if you do, its purely for marketing.

If you look on our website, you can see our still. It has an added step to a "single pass" pot still, a proprietary bit unique to stupfler systems, and for us, unique to north or south america ( and its going to stay that way, as not only are we close family friends with the still maker, but also the American sales rep for stupfler alambics )

What happens, is that we have an "analyzer" that is attached between the chapiteau ( the cooker top) and the condenser. This is where the magic happens that allows us to distill in a "single pass". its an added stage of refinement that produces very palatable spirits right off the condenser.

While i wont discuss what actually happens in the analyzer, i can say that we are not using any scrubbing material in it, and that the reflux does not wash back through the vapor that we end up with. oooo mysterious eh? heh.

im not sure what you mean by temperature management, but we do control the temp and flow of the process water to the analyzer, as well as the heat source. ( direct fire).

I think he's being rather cute and seems to avoid my questions, so I'm real interested in what you guys think...

Re: A Custom Still - Let's break it down...

Posted: Tue Oct 28, 2008 7:47 pm

by Tater

Could be a puker and thumper or maybe 2 thumpers

Re: A Custom Still - Let's break it down...

Posted: Tue Oct 28, 2008 8:10 pm

by Dnderhead

I found where some one ask this and they said they were right

Originally Posted by Bill

Thanks, I'm intrigued. I know the pot still is the first container, and the condenser is the last. There are two other devices in between the the pot and the condenser. Which is the "analyzer" and what is the other? (Mind you I'm not asking for any secrets).

If I had to guess I'd say the second in line is a preheater or possibly a thumper, and the third is your analyzer, but do correct me.

Re: A Custom Still - Let's break it down...

Posted: Tue Oct 28, 2008 8:22 pm

by Dnderhead

also found this --------analyser, has steam rising and wash descending through several levels. So id say it is something like a column atached

to a pot still????

Re: A Custom Still - Let's break it down...

Posted: Wed Oct 29, 2008 4:14 am

by Socrates

Good stuff Dndr. Found it, the distiller then says this...

...the unit on top of the condenser is a preheater... we use this to heat the water we add to our mixtures to shorten heat up times.

and the part in the middle is the analyzer

Look again at the pics for the device in the middle. The pic with the two people gives more of a side view of this "column" - you can see some sort of external loop of tubing attached to it that may give a clue. From the first pic it seems as though the distillate goes from the pot to the bottom of this "analyzer" and exits through the top. I wonder what the external attached loop of tubing does?

And how do you think this "analyzer" works? How would you guess it is controlled? Keep in mind this distiller runs both gin and rum in this device in a single process, so there must be some kind of control of the purity...

Re: A Custom Still - Let's break it down...

Posted: Wed Oct 29, 2008 4:52 am

by Dnderhead

i thank its something like part pot and part "patent" still and the loop mite be a bypass to control the amount of "reflux" (returning part to be redistilled

Re: A Custom Still - Let's break it down...

Posted: Wed Oct 29, 2008 11:26 am

by DrTorque

You said "gin" - could the "analyzer" be where they add the botanicals into the vapor stream, like the Bombay Sapphire process? After all, he said that's where the "magic happens."

Re: A Custom Still - Let's break it down...

Posted: Wed Oct 29, 2008 6:07 pm

by Socrates

Interesting point both of you. The distiller also said:

While i wont discuss what actually happens in the analyzer, i can say that we are not using any scrubbing material in it, and that the reflux does not wash back through the vapor that we end up with. oooo mysterious eh? heh.

Based on this quote, I'm imagining maybe some kind of column with plates, but is this consistent with his statement that "the reflux does not wash back through the vapor we end up with"? I suppose the gin botanicals could be placed somewhere in the path in this column.

Dndr, what do you mean by "patent still"?

Re: A Custom Still - Let's break it down...

Posted: Wed Oct 29, 2008 7:35 pm

by Dnderhead

Yes I believe that's what it is much like the Coffey still but instead of having two columns it has a pot and a column (with plates) not shore if it is a vapor management or liqwid ,thanking vapor (I see no condenser) (I thinking that is a two way valve ( on out put)so they can control what is taking off and what is returned. found one article saying that they put any flavoring in the pot and let soak over night.

Re: A Custom Still - Let's break it down...

Posted: Thu Oct 30, 2008 7:00 am

by violentblue

thats definatly a fine looking getup.

since the builder is in france, I would start off by comparing it to a brandy/Cognac still and look at the differences from there.

it may have some sort of proprietary design but again being that it is from a european still builder, I can't imagine they would stray too far.

Re: A Custom Still - Let's break it down...

Posted: Mon May 12, 2014 5:22 am

by Rhum Junky

Hi there,

Sorry to dig into old posts, but I am also wondering how this still is really working ?

Did someone broke the secret since the last reply ?

Looks to me that this column could be packed with a "home made" structured copper packing and the column is cooled down a bit on its external layer.

So far this looks more like a giant deflag

Cheers !

Re: A Custom Still - Let's break it down...

Posted: Mon May 07, 2018 9:40 pm

by copperstill

The first part is the pot still. The herbs go in here for gin

The second is simular to a thumper on the base with a tube in shell condenser or dephlegmator on top.

The coolant attached to it increases or decreases refulx. This is very usefull if youre trying to hold back highboilers on the back of the run or after the cut when you want to somthing with less of the fatty character. The only thing i cant see is if they are pumping the surpluss condensate back to the pot. In theroy this could be collected when the bases reaches its max capacity and recycled(it is direct fired so the heat cracks chemicals that would build up in steam stills)

The third part which is on top of the condenser(4th part) is the preheater. Its looks like it has a two way valve so if you want to send the vapor through the preheater to heat the next batch you can. Or you can bypass it and go straight into the condenser. If ths was a cognac still you would engage the preheater after you made the cut to tails to prevent messing up the quality of the spirit. In their case if it were me I would run it through the preheater first(which if i had to guess has at most a few coils to prevent full condesation until entering the condenser) only until i got wine to the temp i wanted for preheating then i would switch over to my condensor only as the run further increased in high boilers. Thats all speculation based on this statment of single pass. If it were me Id bet they still make a cut to tails and collect it for further rectification but that is just a guess.