Square Oak Box for Aging?

Moderator: Site Moderator

-

Ricky

- Swill Maker

- Posts: 459

- Joined: Fri Jan 13, 2006 2:38 pm

- Location: Gods Mtn

Square Oak Box for Aging?

i have read the prior post on this subject and a lot of people say that they leak but no one has said this from admitted experiance that i can tell. woody woodchuck made a post that said he did it. virginia gentleman contimplated the idea with much redicule. many have shot it down through theory. goose eye said that it worked for corn beer. i want to hear of someones success or failier. sp a somewhat carpenter could make a box and it would be much cheaper than a barrel. i know barrels are tried and true but a box wouldnt hurt the pocket book as bad. we dont have to relocate or barrels or ship them either. i feel these facts plus the durability of a barrel is why they are preferred. but a box could fit our bill.

and save some bills.

and save some bills.

Day Late;Dollar Short

-

defcon4

- Swill Maker

- Posts: 237

- Joined: Tue Jun 05, 2007 4:09 pm

- Location: Blue rock hurtling 'round the Sun

I thought of the same thing a few days ago, didn't even know there was thread on here about it. I figured it would leak around the corners and such. My idea was to "beef up" the corners on the inside and connect all the sides and such with lap joints or "rabbit" joints (I think they're called that, not sure). My Father is a carpenter, I'll have to go ask him what he could come up with.

An oak box is much more customizable (volume wise) and would be much easier and a LOT cheaper to construct than a barrel would be.

An oak box is much more customizable (volume wise) and would be much easier and a LOT cheaper to construct than a barrel would be.

Towering in gallant fame,

Scotland my mountain hame,

High may your proud

standard gloriously wave,

Land of my high endeavour,

Land of the shining rivers,

Land of my heart for ever,

Scotland the brave!

Scotland my mountain hame,

High may your proud

standard gloriously wave,

Land of my high endeavour,

Land of the shining rivers,

Land of my heart for ever,

Scotland the brave!

-

CoopsOz

- Distiller

- Posts: 1172

- Joined: Wed Aug 16, 2006 4:00 am

- Location: Didjabringyabongalong

Isn't the reason why a barrel works is that as the opposing edges expand, they push on each other? With a square, all the edges will have no resistance on each other.....I really have no idea, that's just my thoughts.

It is most absurdly said, in popular language, of any man, that he is disguised in liquor; for, on the contrary, most men are disguised by sobriety. ~Thomas de Quincy, Confessions of an English Opium-Eater, 1856

-

pintoshine

- Distiller

- Posts: 1132

- Joined: Sun Aug 20, 2006 1:30 pm

wooden troughs hold water quite well. My great grandfather had a wooden container he kept water in all the time.

There was a trick to assembling them though.

The technique is still used for making water tight boxes. The narrow edge is compressed down the center with a hard round thing like a nail on its side. The wood above the compressed slot is plained off. The box is then assembled with a lot of nails. As soon as the box get soaked with water the compressed edges swell and seal the joints.

I searched but I can't find a name for the technique.

There was a trick to assembling them though.

The technique is still used for making water tight boxes. The narrow edge is compressed down the center with a hard round thing like a nail on its side. The wood above the compressed slot is plained off. The box is then assembled with a lot of nails. As soon as the box get soaked with water the compressed edges swell and seal the joints.

I searched but I can't find a name for the technique.

-

tracker0945

- Trainee

- Posts: 906

- Joined: Thu Aug 09, 2007 8:28 pm

- Location: Oztraylia

-

p_su

- Novice

- Posts: 33

- Joined: Mon Oct 08, 2007 11:08 pm

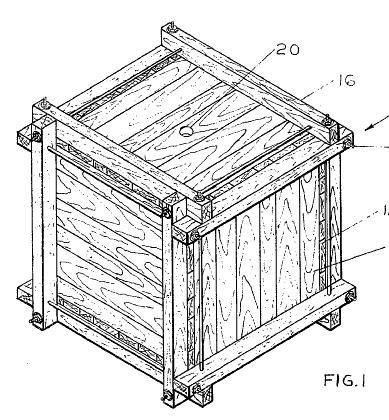

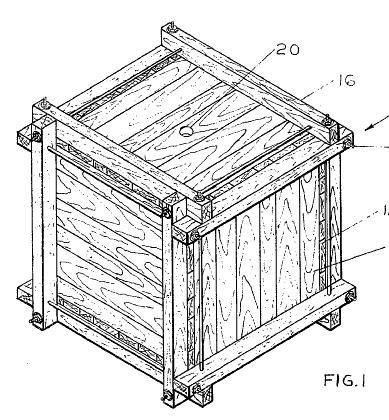

Looks like the square barrel has been made - I found a couple links which may be helpful.

This one is for an inventor who made one - you have to click on the upper left pic to get into the site - not a great website - but a few pics to give you some ideas.

Cybox site

This one is a patent for a square barrel for whiskey aging. Has pictures and everything of how to make it.

Google patent link

Here is another flat sided barrel concept - this one seems to use some angle iron and bolts - allthread could probably be substituted - or handier members could just weld up a frame pretty quick.

Google Patent link #2

*edit*

Just found another example - this one looks like it is by far the easiest to make. No guarenteees these things actually work though..

Yet another patent

Hope the links work - the buttons on this forum are kindof gimpy.

This one is for an inventor who made one - you have to click on the upper left pic to get into the site - not a great website - but a few pics to give you some ideas.

Cybox site

This one is a patent for a square barrel for whiskey aging. Has pictures and everything of how to make it.

Google patent link

Here is another flat sided barrel concept - this one seems to use some angle iron and bolts - allthread could probably be substituted - or handier members could just weld up a frame pretty quick.

Google Patent link #2

*edit*

Just found another example - this one looks like it is by far the easiest to make. No guarenteees these things actually work though..

Yet another patent

Hope the links work - the buttons on this forum are kindof gimpy.

-

rumbaba

- Swill Maker

- Posts: 175

- Joined: Tue Sep 25, 2007 4:11 am

- Location: southern australia

Of all people, some one by the name of coops should knowCoopsOz wrote:Isn't the reason why a barrel works is that as the opposing edges expand, they push on each other? With a square, all the edges will have no resistance on each other.....I really have no idea, that's just my thoughts.

My thought to the propostition of square barrels is this; How many olden day square ships were built?

This is only my opinion mind you, but why try and re-invent the wheel?

-

defcon4

- Swill Maker

- Posts: 237

- Joined: Tue Jun 05, 2007 4:09 pm

- Location: Blue rock hurtling 'round the Sun

I agree but I want a cheaper, easier to build wheel. I don't have time carve a circular shape out out of granite all day just to crack the whole thing when I try to drill an axle hole.rumbaba wrote: but why try and re-invent the wheel?

A box is just easier to make at home without mastering the art of a cooper. Those patent drawing looked like good designs, the second one looked easier.

Towering in gallant fame,

Scotland my mountain hame,

High may your proud

standard gloriously wave,

Land of my high endeavour,

Land of the shining rivers,

Land of my heart for ever,

Scotland the brave!

Scotland my mountain hame,

High may your proud

standard gloriously wave,

Land of my high endeavour,

Land of the shining rivers,

Land of my heart for ever,

Scotland the brave!

-

Ricky

- Swill Maker

- Posts: 459

- Joined: Fri Jan 13, 2006 2:38 pm

- Location: Gods Mtn

-

AfricaUnite

- Swill Maker

- Posts: 275

- Joined: Wed Feb 22, 2006 3:13 pm

- Location: Ontario

I really like the idea of this. I have no source for aged white oak (that I know of) and I am only good at building things that only consist of 2x4's, plywood and screws. This might be a good idea to build as a little business. Im looking at buying a barrel right now, here in Canada I can get a new 38L gibbs american oak med toast for $180. How much do you think it would cost to produce a 38L box? (including labour)

-

rumbaba

- Swill Maker

- Posts: 175

- Joined: Tue Sep 25, 2007 4:11 am

- Location: southern australia

Ricky, it was far from my intention to insult you, I was merely trying to make the point that if it were able to be done as effectively as a barrel I think someone would have done it. I think you will have a great deal of trouble creating an effective seal at the corner joints. I wish you luck if you do have a crack at it.Ricky wrote:P_su i appreciate the links very much. Rumbaba read my post again. i am not trying to reinvent the wheel. i am trying to make something that is within my ability and budget. if you want to fly,airplanes are best but can you afford to build a 747? get the idea?

-

Ricky

- Swill Maker

- Posts: 459

- Joined: Fri Jan 13, 2006 2:38 pm

- Location: Gods Mtn

you didnt insult me. and i agree that a barrel is better. my intentions of this post are to gain knowledge of the subject of a square keg from others tried and true experience. good or bad. i agree that the corners will be dificult to seal but there are more than 2 engineers on this sight that may be able to help. i apologize if i seemed pissed .

Day Late;Dollar Short

-

p_su

- Novice

- Posts: 33

- Joined: Mon Oct 08, 2007 11:08 pm

One more point to consider is the fact that ideas which are impractical/useless for commercial sized operations may be perfectly workable for home-sized use. Perhaps no commercial distilleries or wineries are using square barrels, but I bet many aren't using their stoves or hotplates to run things either  On a small scale, perhaps a square barrel is an ok idea.

On a small scale, perhaps a square barrel is an ok idea.

Here are some pics - pulled from the above links.

This one is the 2nd patent link - the octagon barrel

and this is the last link that I posted.

This one seems to be the easiest to construct - requiring only some allthread, nuts, and some straight cuts of oak. Reading through the text seems to indicate that a tongue and grove might be good to make up the panels. It seems that a table saw and drill press are about all you'd need to make this - no welding or metalwork required.

One other quick point - I just checked at onlineconversion.com - 1 cubic foot will hold 7.5 US liquid gallons. I've no idea of the average volume of spirits which most on the forums are aging - but at least to me 7gals seems like a lot. So perhaps even small box/barrels will suffice for many.

Here are some pics - pulled from the above links.

This one is the 2nd patent link - the octagon barrel

and this is the last link that I posted.

This one seems to be the easiest to construct - requiring only some allthread, nuts, and some straight cuts of oak. Reading through the text seems to indicate that a tongue and grove might be good to make up the panels. It seems that a table saw and drill press are about all you'd need to make this - no welding or metalwork required.

One other quick point - I just checked at onlineconversion.com - 1 cubic foot will hold 7.5 US liquid gallons. I've no idea of the average volume of spirits which most on the forums are aging - but at least to me 7gals seems like a lot. So perhaps even small box/barrels will suffice for many.

-

pintoshine

- Distiller

- Posts: 1132

- Joined: Sun Aug 20, 2006 1:30 pm

You know you bring up a very good point. 7 gallons is a large container.

Why couldn't one, who has access to some dried oak round stock such as 8 inch diameter limbs or small trees, turn out something like a large barrel shaped mug? One could also turn a cork shaped lid or bung to match. This would be good enough for gallon or so. I think I have a spread sheet to estimate the volume by height, width and bilge. I'll look for it.

Why couldn't one, who has access to some dried oak round stock such as 8 inch diameter limbs or small trees, turn out something like a large barrel shaped mug? One could also turn a cork shaped lid or bung to match. This would be good enough for gallon or so. I think I have a spread sheet to estimate the volume by height, width and bilge. I'll look for it.

-

p_su

- Novice

- Posts: 33

- Joined: Mon Oct 08, 2007 11:08 pm

If you have microsoft excel (or equivalent) there are a couple formulas to throw in to calculate out volume.

volume of a cylinder is pi * radius^2 * height

and a conversion factor pulled from onlineconversion - 1 cubic inch = 0.0043290138 US gallons.

Ran some quick numbers - the following combinations will put you right at a gallon or so- listed in pairs of radius and height respectively. (2,18) (3,8) (4,5) (5,3) (6,2)

the excel formula i used (in case I screwed it up and someone wants to check... )

)

for cubic inches =PI()*(R^2)*H

to convert from cu inches to gal = V*0.0043290138

volume of a cylinder is pi * radius^2 * height

and a conversion factor pulled from onlineconversion - 1 cubic inch = 0.0043290138 US gallons.

Ran some quick numbers - the following combinations will put you right at a gallon or so- listed in pairs of radius and height respectively. (2,18) (3,8) (4,5) (5,3) (6,2)

the excel formula i used (in case I screwed it up and someone wants to check...

for cubic inches =PI()*(R^2)*H

to convert from cu inches to gal = V*0.0043290138

-

defcon4

- Swill Maker

- Posts: 237

- Joined: Tue Jun 05, 2007 4:09 pm

- Location: Blue rock hurtling 'round the Sun

I thought you needed staves so that the cracks in between strips of oak would allow breathing to occur. Or could you just cut the walls of this barrel shaped mug thin enough to allow enough breathing to take place?pintoshine wrote:You know you bring up a very good point. 7 gallons is a large container.

Why couldn't one, who has access to some dried oak round stock such as 8 inch diameter limbs or small trees, turn out something like a large barrel shaped mug? One could also turn a cork shaped lid or bung to match. This would be good enough for gallon or so. I think I have a spread sheet to estimate the volume by height, width and bilge. I'll look for it.

Towering in gallant fame,

Scotland my mountain hame,

High may your proud

standard gloriously wave,

Land of my high endeavour,

Land of the shining rivers,

Land of my heart for ever,

Scotland the brave!

Scotland my mountain hame,

High may your proud

standard gloriously wave,

Land of my high endeavour,

Land of the shining rivers,

Land of my heart for ever,

Scotland the brave!

-

pintoshine

- Distiller

- Posts: 1132

- Joined: Sun Aug 20, 2006 1:30 pm

Barrels are completely water and alcohol tight. They are nearly air tight also. That is why they lose so little over the years. There is a crew at every barrel house that makes sure that the barrels stay leak proof. The staves are planed or sanded smooth and then heated bent and banded together so tight they become air tight joints. Every cooperage I have been to uses air pressure, with a small amount of water inside, to check for initial leaks.

The air bubbles whenever there is a leak.

If one wanted, after turning this vessel, they could use a loose fitting lid if they wanted some aeration.

The air bubbles whenever there is a leak.

If one wanted, after turning this vessel, they could use a loose fitting lid if they wanted some aeration.

-

p_su

- Novice

- Posts: 33

- Joined: Mon Oct 08, 2007 11:08 pm

I thought that there was supposed to be a very slight diffusion of gas through the oak planks (over the long term of years - not a quick pressure test) - not necessarily at the joints, but through the material itself - hence what you mentioned pinto - the small losses or "angel's share."

Either way - for our purposes - I think that we can probably ignore the element of aeration or gas exchange, as it seems the primary benefit of oaking for us is the flavors and chemicals that are leached out of the wood.

Either way - for our purposes - I think that we can probably ignore the element of aeration or gas exchange, as it seems the primary benefit of oaking for us is the flavors and chemicals that are leached out of the wood.

-

Cruiser

- Bootlegger

- Posts: 112

- Joined: Tue Feb 13, 2007 7:42 pm

- Location: New Zealand's large western island!

Problem with turning a barrel shaped object from a solid chunk of wood is that the grain and sap vessels all run the wrong way. It would leak like a sieve especially at the bottom where you have an end-grain issue.

In a normal cask the staves a cut in a particular way to ensure no grain or vessels travel across ways through the wood. Even then you can still have leaks.

Also, I think a turned barrel would quickly split.

Cruiser.

In a normal cask the staves a cut in a particular way to ensure no grain or vessels travel across ways through the wood. Even then you can still have leaks.

Also, I think a turned barrel would quickly split.

Cruiser.

-

Ricky

- Swill Maker

- Posts: 459

- Joined: Fri Jan 13, 2006 2:38 pm

- Location: Gods Mtn

i happen to have a hollow oak that is probably 6" the hole that is. i could try to make it hold water with a little effort just to experament with. i know it wouldnt be suitable for spirits but we might learn something. i agree with cruiser on the splitting idea. i might give it a try just to see.

Day Late;Dollar Short

-

MisterSteve124

- Swill Maker

- Posts: 201

- Joined: Mon Nov 26, 2007 6:25 pm

-

MisterSteve124

- Swill Maker

- Posts: 201

- Joined: Mon Nov 26, 2007 6:25 pm

-

MikeyT

- Swill Maker

- Posts: 218

- Joined: Sun Mar 04, 2007 2:04 pm

This router bit might give you some ideas. Need to select very straight grain quarter sawn white oak for the sides. The width of the boards determine the final diameter.

http://www.leevalley.com/wood/page.aspx ... at=1,46168" onclick="window.open(this.href);return false;" rel="nofollow

If you cut a very tight rabbet about 1" in from the ends, on the inside, then the 'barrel' ends could be made out of a single piece of lumber. For the ends, I would use flat sawn boards, not quarter sawn. There, you want the grain on the flat of the board to be real squirley, not straight. Boards for the sides should be at least 3/4" thick, maybe 7/8". Sharp edges on the outside could be planed down.

Clamps could be made by bending 1/16" x 1" galvanized steel bands and tightning with bolts. Cork under the bands would prevent iron from leaching into the wood. Automotive stores have cork gasket material.

Just throwing out ideas.

http://www.leevalley.com/wood/page.aspx ... at=1,46168" onclick="window.open(this.href);return false;" rel="nofollow

If you cut a very tight rabbet about 1" in from the ends, on the inside, then the 'barrel' ends could be made out of a single piece of lumber. For the ends, I would use flat sawn boards, not quarter sawn. There, you want the grain on the flat of the board to be real squirley, not straight. Boards for the sides should be at least 3/4" thick, maybe 7/8". Sharp edges on the outside could be planed down.

Clamps could be made by bending 1/16" x 1" galvanized steel bands and tightning with bolts. Cork under the bands would prevent iron from leaching into the wood. Automotive stores have cork gasket material.

Just throwing out ideas.

-

arkansas

- Bootlegger

- Posts: 149

- Joined: Wed Nov 22, 2006 5:17 pm

- Location: Arkansas

One little bit of info on the drill out the log idea, won't work as previously mentioned grain is all wrong and the chance for cracking and split is very high. MikeyT, you hit on a very good idea in my opinion except for the flat sawn boards for the top and bottom, quart sawn boards from the white oak family are about the only speices that do what you are looking for with out imparting unwanted falvors, that I am aware of. Just my 2 cents, with countless hours sawning staves and barrel heading.

-

Woody_Woodchuck

- Novice

- Posts: 60

- Joined: Tue Nov 13, 2007 4:18 am

- Location: Flatlands of central NC

I made my “square barrels” using a table saw and chisel. As MikeyT mentioned I rabbited and tongue & grooved the joints. For the bottom, I did have a nice 12”+ wide board. All these white oak boards were from the barn, stacked and aged for who knows how long.

After cleaning, sizing and plaining the stock to 3/4", I did a full rabbit around the bottom, ¾” wide around the edges of a 12” x 12” slab, ¾” from the edges. This was maybe 3/8” deep or about half way through. I cut the majority on the saw and finished the corners using the chisel. On the sides I did the same rabbit for the end joints. I used narrower boards on the sides due to the warping of the wider ones. For the actual corners where the sides meet the bottom, use your judgment and skills. If you can cut and chisel, keep the loop closed on the bottom. If you’re lacking there make two opposite grooves all the way across the bottom.

The one nice, wide, thick, flat one I saved for all the bottoms. I tongue and grooved the edges on a couple boards so they fit together nice. Good deep T&G as I recall ½” or so. For the top I used the same rabbit slot as on the bottom, used narrower T&G boards for the top so had to put them together also. I recall beveling them some so the top would slip on and off easier. I knew I’d have my grubby paws in there more than a couple times checking on how things were going. To keep the top somewhat tight I set a good size rock on it and set the whole thing out on the back (North facing) porch.

For all the joints I made them snug but not so tight as you’d have to pound the heck out of them. They would slip together with a little persuasion but not split or chip. For finish fitting I used a hand plane and small chisel to make those little adjustments. I used some little brass screws to hold the top corners of the sides together, not too many were needed only at the top. Four more held the bottom on, or was it eight, used enough so it wouldn’t fall apart anyway.

Put it all together and soaked it in the creek for a couple days, with a rock inside and one on top. First one held water just as nice as you’d please, thought this was an easy project. Second one, joints were a bit loose and they never did swell closed. About every other one worked great first try and the others I dried and tried again.

After cleaning, sizing and plaining the stock to 3/4", I did a full rabbit around the bottom, ¾” wide around the edges of a 12” x 12” slab, ¾” from the edges. This was maybe 3/8” deep or about half way through. I cut the majority on the saw and finished the corners using the chisel. On the sides I did the same rabbit for the end joints. I used narrower boards on the sides due to the warping of the wider ones. For the actual corners where the sides meet the bottom, use your judgment and skills. If you can cut and chisel, keep the loop closed on the bottom. If you’re lacking there make two opposite grooves all the way across the bottom.

The one nice, wide, thick, flat one I saved for all the bottoms. I tongue and grooved the edges on a couple boards so they fit together nice. Good deep T&G as I recall ½” or so. For the top I used the same rabbit slot as on the bottom, used narrower T&G boards for the top so had to put them together also. I recall beveling them some so the top would slip on and off easier. I knew I’d have my grubby paws in there more than a couple times checking on how things were going. To keep the top somewhat tight I set a good size rock on it and set the whole thing out on the back (North facing) porch.

For all the joints I made them snug but not so tight as you’d have to pound the heck out of them. They would slip together with a little persuasion but not split or chip. For finish fitting I used a hand plane and small chisel to make those little adjustments. I used some little brass screws to hold the top corners of the sides together, not too many were needed only at the top. Four more held the bottom on, or was it eight, used enough so it wouldn’t fall apart anyway.

Put it all together and soaked it in the creek for a couple days, with a rock inside and one on top. First one held water just as nice as you’d please, thought this was an easy project. Second one, joints were a bit loose and they never did swell closed. About every other one worked great first try and the others I dried and tried again.