FLUTE TALK

Moderator: Site Moderator

-

Kentucky shinner

- Master of Distillation

- Posts: 3017

- Joined: Tue Jan 19, 2010 8:04 pm

- Location: Paradise? Western KY

Re: FLUTE TALK

I also chuck my bit in far enough that just enough drill bit is sticking out of the chuck to go through the plates... Less chance of twist..

Re: FLUTE TALK

Thanks for the tips fellas. I think I also am using a little too thick of material for the plates with 1/8". My plan is to go back to my original plan of using valves like I'm used to here in the refinery. My tree of plates hangs under a drop in dephleg like OD first dreamed up, so let me get my confidence back and I'll make another tree with perfs after I get this coonass flute up and running! Hoping to get my column and keg back from the welder this week so I can start final assembly.

Re: FLUTE TALK

I don't consider the thickness of the plate being important, but the fit and angle to the column is, apart from the center support, I drill 4 holes around the edge of the plate and insert hard silver rods through the holes, these are soldered to the plate with soft solder forming like a cage to keep the whole assembly square.

OD

OD

OLD DOG LEARNING NEW TRICKS ......

-

moonshiner dave

- Novice

- Posts: 91

- Joined: Sat Feb 03, 2007 9:38 pm

Re: FLUTE TALK

I think your right OD. I built my plates from 16 oz. sheet, and as far as I know, they work wonderfully.olddog wrote:I don't consider the thickness of the plate being important

OD

The stone age didn't end due to a lack of stones

-

Kentucky shinner

- Master of Distillation

- Posts: 3017

- Joined: Tue Jan 19, 2010 8:04 pm

- Location: Paradise? Western KY

Re: FLUTE TALK

I totally agree. Thickness does not matter at all. Your plate only has to be strong enough to support liquid. I like the idea OD has with the cage to keep everything nice and square.

Re: FLUTE TALK

I've been lusting after a flute since the first one I saw, but it's gonna be awhile till I can afford the build. In the meantime, I'm wondering why the two 90's at the top of the dephleg are 2". It seems like if you're going to reduce down to 1" or 3/4" you could just do it at the top of the column and reduce the cost of those fitting substantially (2" fittings here are around $20 apiece). Is the 2" aesthetic or structural? Or is the intention to keep the vapor speed at that point lower so the tails cutoff happens automatically. Is this similar to how the VM tails cutoff functions, based on the density of alchohol?

Re: FLUTE TALK

OH, also - we use these guys a lot for perforated architectural metals: http://www.hkperf.com/. I'm not sure if they have copper in stock, but I know they have stainless. Might be easier to get a sheet of pre-perforated sheet and then cut it into a proper disc than to try fabricating the holes at home. Would also allow comparisons between builds to be somewhat more standardized.

-

Kiwi-lembic

- Swill Maker

- Posts: 264

- Joined: Fri Jul 02, 2010 10:50 pm

- Location: New Zealand

Re: FLUTE TALK

So if you found perforated sheet with approx 30% hole surface area would this suit these flute plates ???

Re: FLUTE TALK

When you have spent all the dollars to buy 4"tube and fittings etc. why would you want to skimp on the cost of a couple of fitings, just to save say $10-15 overall.kerinin wrote:I'm wondering why the two 90's at the top of the dephleg are 2". It seems like if you're going to reduce down to 1" or 3/4" you could just do it at the top of the column and reduce the cost of those fitting substantially (2" fittings here are around $20 apiece).

OD

OLD DOG LEARNING NEW TRICKS ......

- thepatchworkdoll

- Swill Maker

- Posts: 189

- Joined: Tue Jan 29, 2008 4:12 pm

- Location: From the land of Heather & Heiland Coos

Re: FLUTE TALK

Hey All experienced plate/bubble cap builders. Can you please advise what the reccommended thickness the plates are meant to be.

Any info realy appreciated.

Regards

Thepatchworkdoll

Any info realy appreciated.

Regards

Thepatchworkdoll

Re: FLUTE TALK

Patchwork, I went with 1/8" plate. In hindsight that's probably at least twice the thickness needed. I have also decided to go with valve trays which was my original plan anyway. Pretty damn excited with the way they turned out!

Re: FLUTE TALK

Don't think it really matters as long as it has more structual integrity than say,,,,foilthepatchworkdoll wrote:Can you please advise what the reccommended thickness the plates are meant to be.

The plates only support a really small bit of liquid and temps are relatively low.

Base/floor plates on my rig (which do offer support based on my design) is 27-28 gage sheet

One of the original goals was to keep the builds simple.

Good luck

Trample the injured and hurdle the dead.

Re: FLUTE TALK

Agreed - I asked more to try to understand the design parameters.olddog wrote:When you have spent all the dollars to buy 4"tube and fittings etc. why would you want to skimp on the cost of a couple of fitings, just to save say $10-15 overall.

Re: FLUTE TALK

In this particular instance, tubing size at that particular location being reduced may not impact the design with any measureable amount of performance change.kerinin wrote:Agreed - I asked more to try to understand the design parameters.

Trample the injured and hurdle the dead.

Re: FLUTE TALK

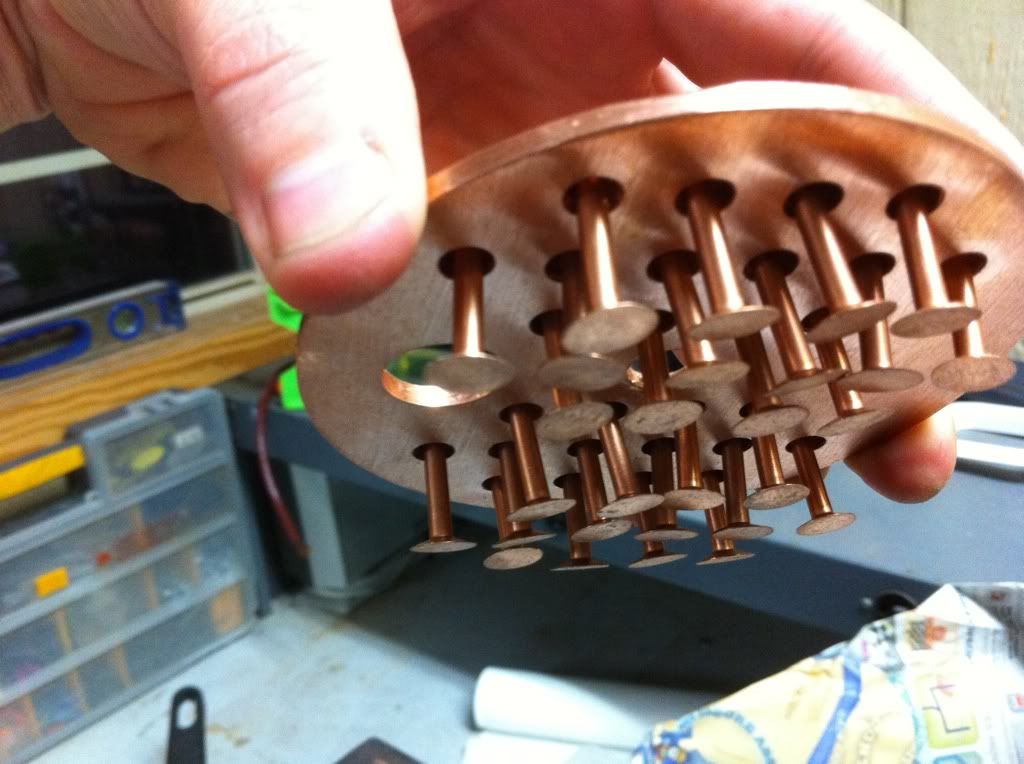

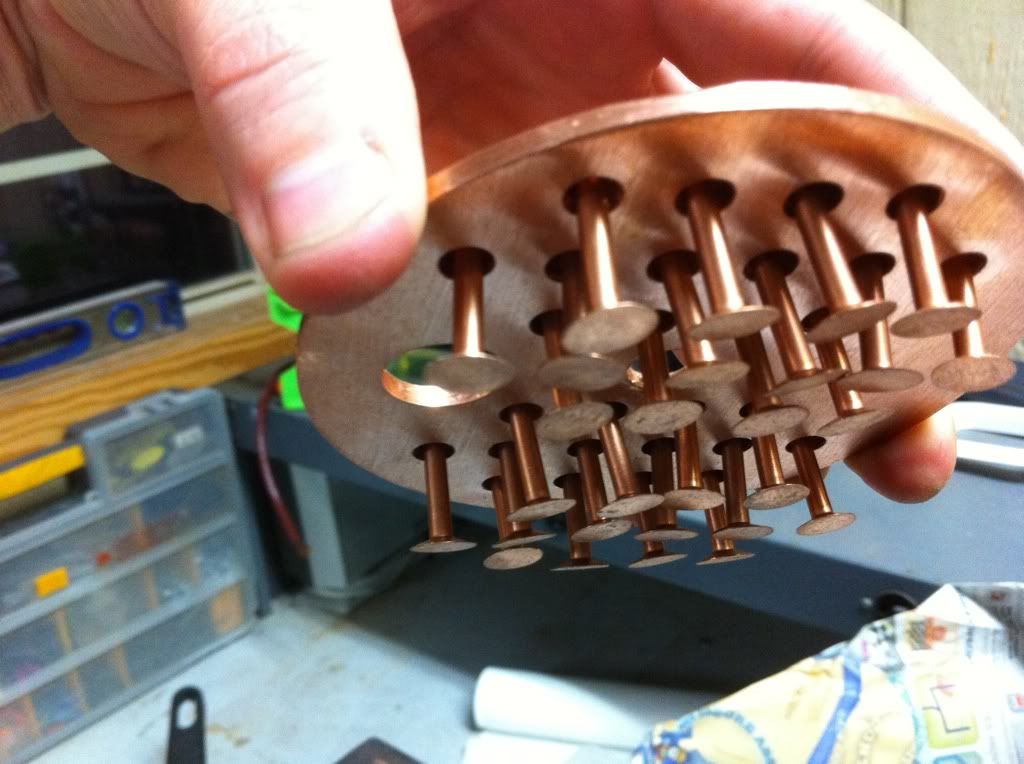

They're made from 3/4" long blujean/saddle rivets with a 1/8" shank. Someone else here deceives credit for that idea... Maybe OD? Instead of having to get hole size anemones of holes calculations close to perfect, these should be adjustable only opening as much as necessary while eliminating the possibility of huge pressure drops across each plate.Prairiepiss wrote:RayDean That's one hell of a hevyduty plate!!!!Very nice. What did you make your valves out of?

Re: FLUTE TALK

That's what I suspected, good to have a 2nd opinion. Might be a useful thing to keep in mind, given that some members are working on 'starter' flutes with the intention of building lower-cost entry level versions that produce similar results.LWTCS wrote:In this particular instance, tubing size at that particular location being reduced may not impact the design with any measureable amount of performance change.

Re: FLUTE TALK

I've been reading me way through this thread (sheesh it's long...) and trying to internalize all the information.

One idea I just had relates to the discussion of 2" flutes and the speed tradeoff vs a 4" column. I wonder what the impact of increasing the condensate depth would be? A 4" column has 4x the cross-sectional area of a 2" column - what if the condensate depth was increased from 1/2" to 2" (is that 1/2" figure what most of you guys are using?) - that way the volume of condensate at each plate would be the same. One difference that seems interesting is that the bubbles would be rising through a taller liquid column, so each plate might equilibrate faster. On the flip side, the vapor pressure needed for the vapor to 'bubble' would be 4x (am I right here - pressure increases linearly with height, right?) as high.

I guess the idea would be that you mitigate the increase in vapor speed by increasing the vapor/condensate interface area, possibly allowing a smaller column to be driven at a similar speed.

One idea I just had relates to the discussion of 2" flutes and the speed tradeoff vs a 4" column. I wonder what the impact of increasing the condensate depth would be? A 4" column has 4x the cross-sectional area of a 2" column - what if the condensate depth was increased from 1/2" to 2" (is that 1/2" figure what most of you guys are using?) - that way the volume of condensate at each plate would be the same. One difference that seems interesting is that the bubbles would be rising through a taller liquid column, so each plate might equilibrate faster. On the flip side, the vapor pressure needed for the vapor to 'bubble' would be 4x (am I right here - pressure increases linearly with height, right?) as high.

I guess the idea would be that you mitigate the increase in vapor speed by increasing the vapor/condensate interface area, possibly allowing a smaller column to be driven at a similar speed.

Re: FLUTE TALK

Good point Kernin.

My actual column (on my tower) is only 1.5.

The 4" on my rig is merly the vessel that holds my thumper juice. Any traveling as such by the vapor is done within the constraints of the 1.5.

And my still will piss like a race horse. I'm not a true member of the 4" club.

Please continue with that line of thinking.

My actual column (on my tower) is only 1.5.

The 4" on my rig is merly the vessel that holds my thumper juice. Any traveling as such by the vapor is done within the constraints of the 1.5.

And my still will piss like a race horse. I'm not a true member of the 4" club.

Please continue with that line of thinking.

Trample the injured and hurdle the dead.

Re: FLUTE TALK

I guess the challenge (in building a 2" column) would be that there are two things going on at each tray - vapor from below is entering and being cooled, and the liquid is boiling / evaporating providing vapor for the plate above. Increasing the liquid depth might address the heat transfer from the incoming vapor, but you'd still have a much smaller surface area for evaporation to happen.

One thing I don't think I understand is how to think about the vapor moving between plates. In my mind the idealized version of what's happening is that incoming vapor transfers heat from the lower plate as it condenses (while it's moving through the liquid in the plate). Since the liquid and vapor in the plate are in thermal equilibrium, the added heat causes some of the liquid to vaporize, creating the vapor for the next plate.

If this is reasonably close to what's actually happening, it seems like the fluid depth is more important than its surface area, as the vapor going to the next plate is being created via a phase change within the fluid, rather than through evaporation from the surface. Does this sound right to you guys who know more than I do about the physics?

One thing I don't think I understand is how to think about the vapor moving between plates. In my mind the idealized version of what's happening is that incoming vapor transfers heat from the lower plate as it condenses (while it's moving through the liquid in the plate). Since the liquid and vapor in the plate are in thermal equilibrium, the added heat causes some of the liquid to vaporize, creating the vapor for the next plate.

If this is reasonably close to what's actually happening, it seems like the fluid depth is more important than its surface area, as the vapor going to the next plate is being created via a phase change within the fluid, rather than through evaporation from the surface. Does this sound right to you guys who know more than I do about the physics?

Re: FLUTE TALK

Good points to think about Kernin.

Loneswinger has made some calculations with a clculator that he built that has helped me determine what happens with my rig. My most recent question to him addresses exactly what you are talking about now.

I too would like to know how any peticular volume of liquid may impact performance.

Consider this too. As the abv increases at each succesive chamber hieght, less heat will be required as boiling points up the line will get lower.kerinin wrote:One thing I don't think I understand is how to think about the vapor moving between plates. In my mind the idealized version of what's happening is that incoming vapor transfers heat from the lower plate as it condenses (while it's moving through the liquid in the plate). Since the liquid and vapor in the plate are in thermal equilibrium, the added heat causes some of the liquid to vaporize, creating the vapor for the next plate.

Loneswinger has made some calculations with a clculator that he built that has helped me determine what happens with my rig. My most recent question to him addresses exactly what you are talking about now.

I too would like to know how any peticular volume of liquid may impact performance.

Trample the injured and hurdle the dead.

Re: FLUTE TALK

Thanks, I'll take a look. This train of thought lead me way off the topic of this thread, so I started a new one in the research & theory portion:

http://homedistiller.org/forum/viewtopi ... =1&t=20473

http://homedistiller.org/forum/viewtopi ... =1&t=20473

-

Prairiepiss

- retired

- Posts: 16571

- Joined: Sat Dec 18, 2010 7:42 am

- Location: Somewhere in the Ozarks

Re: FLUTE TALK

I have seen many different plate drain down combers being used. Dependent on if the plates are fixed or removable. I had an idea for down combers for a removable plate. I wanted to get your opinions on. Most if not all are placed to one side of the plate. Thinking from what I can tell is so the dropping fluid from the upper plate has more reaction time moving across the the lower plate to the drain to the next plate. And so it doesn't come straight down from one drain right into the next. I was thinking about a central drain right in the middle of the plate. The drain on the upper plate would have a cap or hood to keep the falling fluid from just going right down to the lower plate. The bottom of the drain would have a cap on it like a upside down bubble cap to act as a trap. Maybe flare this cap so the draining fluid has a wider drop pattern? But I thinking from what I have seen the fluid on the plates are moving/bubbling so violently that the falling fluid would mix quite well with it before draining down to the next plate. Keep in mind I'm thinking about a removable perforated plate here. I was looking at making every plate exactly the same. Or as close as I can. And placement in the column would be the same for all plates no matter how you placed them in it. Where if you use the J traps you would have to alternate the drains from side to side. I made a crude paint pic to show you kinda what I was thinking. Its not to any kind of scale. Just an idea. What do you think will it work or should I round file it?

- Attachments

-

- Center down combers.gif (2.93 KiB) Viewed 2581 times

It'snotsocoldnow.

Advice For newbies by a newbie.

CM Still Mods

My Stuffs

Fu Man

Mr. Piss

That's Princess Piss to the haters.

Advice For newbies by a newbie.

CM Still Mods

My Stuffs

Fu Man

Mr. Piss

That's Princess Piss to the haters.

-

Kentucky shinner

- Master of Distillation

- Posts: 3017

- Joined: Tue Jan 19, 2010 8:04 pm

- Location: Paradise? Western KY

Re: FLUTE TALK

I see know reason that this wont work. Looks like some good thinking. I have had thought along the same lines. I have though about soldering the cap on the bottom of the downcomer to the tube, instead of the on the plate.

KS

KS

-

Prairiepiss

- retired

- Posts: 16571

- Joined: Sat Dec 18, 2010 7:42 am

- Location: Somewhere in the Ozarks

Re: FLUTE TALK

Oh that's what I planed on doing to begin with KS. I would just like to center them if I could.

It'snotsocoldnow.

Advice For newbies by a newbie.

CM Still Mods

My Stuffs

Fu Man

Mr. Piss

That's Princess Piss to the haters.

Advice For newbies by a newbie.

CM Still Mods

My Stuffs

Fu Man

Mr. Piss

That's Princess Piss to the haters.

Re: FLUTE TALK

PP - I like that design, it's very elegant.

I've been trying to understand sieve plates better, and I was hoping some of you guys could clarify some things for me. Not trying to start a sieve/bubble cap flame war...

One of the arguments for sieve plates I've seen is that they 'cut off' as the tails approach, based on (as far as I can tell) the change in surface tension as the % water in the condensate increases. What's confusing to me is that as far as I can tell, water has a higher surface tension (in air, at least) than ethanol (Wikipedia: http://en.wikipedia.org/wiki/Surface_tension_values: water/air @ 72mN·m–1, ethanol/air @ 22mN·m–1). It would seem like ethanol having a lower surface tension would make it more likely to drain through the perforations.

Since this doesn't make any sense to me, I wonder if there's another explanation; if we assume constant heat through the run and recirculating coolant, as the temperature of the coolant increases the heat transfer between the dephleg and the rising vapor will decrease (heat transfer is proportional to the temperature difference between the coolant and the vapor). Since less heat is being transferred, less vapor is being condensed, and since less condensate is being produced, the volume of condensate in the column drops, leading to the lower plates going dry (since it's starting at the top and draining down).

Has anyone observed the plates 'turning off' in cases where coolant *isn't* being recirculated? If this explanation is correct, I would expect to see the lower plates remain filled if the coolant temperature and flow was kept the same through the run, since the vapor temperature increases through the run (thus increasing the heat transfer).

I've been trying to understand sieve plates better, and I was hoping some of you guys could clarify some things for me. Not trying to start a sieve/bubble cap flame war...

One of the arguments for sieve plates I've seen is that they 'cut off' as the tails approach, based on (as far as I can tell) the change in surface tension as the % water in the condensate increases. What's confusing to me is that as far as I can tell, water has a higher surface tension (in air, at least) than ethanol (Wikipedia: http://en.wikipedia.org/wiki/Surface_tension_values: water/air @ 72mN·m–1, ethanol/air @ 22mN·m–1). It would seem like ethanol having a lower surface tension would make it more likely to drain through the perforations.

Since this doesn't make any sense to me, I wonder if there's another explanation; if we assume constant heat through the run and recirculating coolant, as the temperature of the coolant increases the heat transfer between the dephleg and the rising vapor will decrease (heat transfer is proportional to the temperature difference between the coolant and the vapor). Since less heat is being transferred, less vapor is being condensed, and since less condensate is being produced, the volume of condensate in the column drops, leading to the lower plates going dry (since it's starting at the top and draining down).

Has anyone observed the plates 'turning off' in cases where coolant *isn't* being recirculated? If this explanation is correct, I would expect to see the lower plates remain filled if the coolant temperature and flow was kept the same through the run, since the vapor temperature increases through the run (thus increasing the heat transfer).

-

Austin Nichols

- Rumrunner

- Posts: 723

- Joined: Thu Jun 24, 2010 8:57 pm

- Location: Dow nunda QLD

-

Austin Nichols

- Rumrunner

- Posts: 723

- Joined: Thu Jun 24, 2010 8:57 pm

- Location: Dow nunda QLD

Re: FLUTE TALK

Yes it is mateolddog wrote:Is this a new build Austin?

OD

-

Prairiepiss

- retired

- Posts: 16571

- Joined: Sat Dec 18, 2010 7:42 am

- Location: Somewhere in the Ozarks

Re: FLUTE TALK

Those brass unions are HUUUUGE!

It'snotsocoldnow.

Advice For newbies by a newbie.

CM Still Mods

My Stuffs

Fu Man

Mr. Piss

That's Princess Piss to the haters.

Advice For newbies by a newbie.

CM Still Mods

My Stuffs

Fu Man

Mr. Piss

That's Princess Piss to the haters.

Re: FLUTE TALK

seems like new buids are in the air!!!!!!

riddle me this.. iv got a 36" piece of 4" copper and i only wanna use 4 plates in it. what,, if any,, do yall think that the difference would be in puting the four plates in the upper half ,,, or the lower half?? ill end up having about 15" of (void copper) so should the "void" be in the lower part,, or in the upper part???? ill post pics if needed.

thanks

spooky

riddle me this.. iv got a 36" piece of 4" copper and i only wanna use 4 plates in it. what,, if any,, do yall think that the difference would be in puting the four plates in the upper half ,,, or the lower half?? ill end up having about 15" of (void copper) so should the "void" be in the lower part,, or in the upper part???? ill post pics if needed.

thanks

spooky

4" plate column >>>[/color] the flame that burns twice as bright only burns half as long