Page 1 of 1

Bubble Plate Still... New Spin?

Posted: Thu Jun 17, 2010 11:31 am

by diesel4ever

Was reading the post by Rednose about bubble plate technology and how to make it work in a smaller scale column system and the hamsters jumped on the wheel in my head and came up with this...

What if you took some superfine stainless screen and cut it just a little larger in diameter of your column and using some kind of plunger to keep it level placed it in the tube and did this every 2 inches all the way to the slanted diverter plates or if using a VM to just below your "T"??? The screen would trap alcohol yet allow vapor to pass through right? Well only one way to find out if this will work... Build it!

Comments? Suggestions?

Re: Bubble Plate Still... New Spin?

Posted: Thu Jun 17, 2010 12:01 pm

by ScottishBoy

If you build it...you will build another

...and another

...and another...

Re: Bubble Plate Still... New Spin?

Posted: Thu Jun 17, 2010 1:39 pm

by rednose

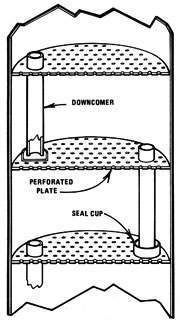

That's nothing new and works fine.

- bubble screen

- bubble%20plate.jpg (12.02 KiB) Viewed 9540 times

Re: Bubble Plate Still... New Spin?

Posted: Thu Jun 17, 2010 4:12 pm

by diesel4ever

Thanks rednose for the diagram. That's like what I was talking about only without the overflow tubes. I wonder how efficient it would be? Does each screen account for a level of reflux?

Re: Bubble Plate Still... New Spin?

Posted: Thu Jun 17, 2010 4:29 pm

by rednose

Books say that it's same efficient than bubble caps but much easier to make.

There is a relation on the total plate surface and max percentage of holes, OD knows the formula.

Most of his still plates are based on perforated plates.

You need the downcomers, otherwise your still will have some kind of pumping effect and throw liquid instead of vapor in the condenser

Re: Bubble Plate Still... New Spin?

Posted: Thu Jun 17, 2010 4:31 pm

by olddog

Re: Bubble Plate Still... New Spin?

Posted: Thu Jun 17, 2010 10:58 pm

by diesel4ever

WOW a 4" column! I have column envy... the reason I want to go with the fine SS screen is because (I think/hope) that the improved surface area will increase efficiency for each plate. I picked up a 4' length of 3" dia. pipe and was planning on making a removable head section which includes the slant plates and drain tubing but open at the top so I can drop in a cooling coil. That way if the screens don't work like I want them to I can just remove them and replace them with packing. I'm planning on installing 10 screens, one every 4" I'm hoping it I can allow me to produce 96% pure spirits from 13% wash at a rate of 4 litres per hour. Looking to try my hand at biodiesel production and the only way to do that is to make more spirit than I can drink... Maybe I should go to 6 inch column...

Re: Bubble Plate Still... New Spin?

Posted: Fri Jun 18, 2010 2:53 am

by manu de hanoi

rednose wrote:That's nothing new and works fine.

bubble%20plate.jpg

No It doesnt, I tried what the Diesel suggested with superfine ss mesh. Just fill a bucket with water and then put the mesh in, then blow some air below the mesh with a hose or something. Because the holes are so close to each other the vapor isnt split into fine bubbles but goes through the mesh in bulk (like one hudge bubble).

so you may use fine ss mesh as packing but not as tray plate.

Re: Bubble Plate Still... New Spin?

Posted: Fri Jun 18, 2010 2:54 am

by olddog

I think your screens would be unsuitable, the holes in a perforated plate should take up 30% of the surface area, screens would be far more than that. Just make a plate assembly on a 1/4"center tube, you can pull the whole assembly out then.

BTW plates need to be between 4-6"apart, work out your height from there depending on how many you use.

OD

Re: Bubble Plate Still... New Spin?

Posted: Fri Jun 18, 2010 8:03 am

by rednose

manu de hanoi wrote:rednose wrote:That's nothing new and works fine.

bubble%20plate.jpg

No It doesnt, ....

yes it does and I and OD posted the secret why it does:

There is a relation on the total plate surface and max percentage of holes, OD knows the formula.

....the holes in a perforated plate should take up 30% of the surface area

My "Apollo Still" works based on this concept, would be sad to have a still that doesn't work.

I wouldn't even come to the idea to use packing material as plate material.

Joe

Re: Bubble Plate Still... New Spin?

Posted: Fri Jun 18, 2010 8:22 am

by manu de hanoi

we are not talking about your still joe ! Sorry if my post seemed otherwise

Re: Bubble Plate Still... New Spin?

Posted: Fri Jun 18, 2010 8:38 am

by rednose

manu de hanoi wrote:we are not talking about your still joe ! Sorry if my post seemed otherwise

No way Manu, I think, re-reading the first post, the problem is by me misunderstanding the word screen.

If the OP meant a material like the window mosquito protection but in SS and very fine (woven wires) than you are right, that won’t work.

You know, the language problem sometimes, lol.

By the way: how did your yuca project turn out?

Re: Bubble Plate Still... New Spin?

Posted: Fri Jun 18, 2010 9:41 am

by manu de hanoi

rednose wrote:

By the way: how did your yuca project turn out?

must be someone else

Re: Bubble Plate Still... New Spin?

Posted: Fri Jun 18, 2010 11:40 am

by rednose

manu de hanoi wrote:rednose wrote:

By the way: how did your yuca project turn out?

must be someone else

Isn't that you?

http://homedistiller.org/forum/viewtopi ... a#p6773740

Cassava is yuca.

Don't make me think that I'm getting old.

joe

Re: Bubble Plate Still... New Spin?

Posted: Fri Jun 18, 2010 10:20 pm

by manu de hanoi

out of topic !!!!

Re: Bubble Plate Still... New Spin?

Posted: Sat Jun 19, 2010 5:53 am

by Chasin' Tales

diesel4ever wrote:WOW a 4" column! I have column envy... the reason I want to go with the fine SS screen is because (I think/hope) that the improved surface area will increase efficiency for each plate. I picked up a 4' length of 3" dia. pipe and was planning on making a removable head section which includes the slant plates and drain tubing but open at the top so I can drop in a cooling coil. That way if the screens don't work like I want them to I can just remove them and replace them with packing. I'm planning on installing 10 screens, one every 4" I'm hoping it I can allow me to produce 96% pure spirits from 13% wash at a rate of 4 litres per hour. Looking to try my hand at biodiesel production and the only way to do that is to make more spirit than I can drink... Maybe I should go to 6 inch column...

I'm thinking you would be a lot better off just packing the column w/ copper mesh from the get go and scrapping the SS screen sieve plate idea. JMHO.

Re: Bubble Plate Still... New Spin?

Posted: Sat Jun 19, 2010 7:38 pm

by diesel4ever

Well for starters you can't compare cold air trying to pass through a fine screen in a bucket of water with hot alcohol vapor passing through a screen with hot alcohol on the other side. water is extremely cohesive compared to alcohol. Also the screen I'm going to use is approximately 33% hole. I know that when I pour feints in the range of 85% ABV on it it passes through easily but the screen stays fully wet when flow stops. I'm also pretty sure that there is no rule for the minimum distance between screens. If that was the case you might at well make sure there's at least 6" between your scrubbers... The more screens the more vapor/liquid exchange.

Re: Bubble Plate Still... New Spin?

Posted: Sat Jun 19, 2010 8:01 pm

by squidd

Hi D4e,

I believe that no one can say it won't work, unless it has actually been tried and found not to.

Some time ago, I had a similar idea, but never carried it through.

I sliced 1/2" ring off a a piece of 2" copper tubing, removed some material from its perimeter to make its diameter small

enough for the ring to just slide easily into the 2" tubing. I then soldered some copper screen across the ring face.

The idea was to make a numer of these, and stack them into the column.

By pressing across the screen, it can be made slightly convex or concave.

So, a convex screen would direct the reflux towards the center of the next ring, which would be concave and direct the reflux towards the edges of the next one, and so on.

You may be the man to enlighten us.

Cheers,

squidd

Re: Bubble Plate Still... New Spin?

Posted: Sat Jun 19, 2010 9:43 pm

by diesel4ever

Why thank you squidd. Finally a cheering squad. I actually though of doing something like what you had engineered but me being kinda lazy and obsessed with finding an easier way to do something I came up with the screen idea. going to try to keep mine as flat as possible. I'm also kinda thinking about placing tiny drops of solder on the bottoms of the screen to direct the drips more evenly on the screen below.

Re: Bubble Plate Still... New Spin?

Posted: Sun Jun 20, 2010 1:24 am

by olddog

Have a read of this Diesel, it might explain plated stills a bit better for you, particularly chapter 7

http://journeytoforever.org/biofuel_lib ... meToC.html" onclick="window.open(this.href);return false;" rel="nofollow

I know the site is a fuel site but there are a lot of reference to alcohol stills too

OD

Re: Bubble Plate Still... New Spin?

Posted: Tue Nov 17, 2015 11:44 pm

by howsey

been looking in to these. does anyone know if old centrifugal screens from a sugar mill would work? can get them in copper, brass, stainless or nickel. I know the copper ones make a good foot valve strainer for my bore pump.

Re: Bubble Plate Still... New Spin?

Posted: Wed Nov 18, 2015 12:02 am

by Yummyrum

howsey wrote:been looking in to these. does anyone know if old centrifugal screens from a sugar mill would work? can get them in copper, brass, stainless or nickel. I know the copper ones make a good foot valve strainer for my bore pump.

LOL howsey , I remember staring at the strainer in my Coffee perculator thinking it might make a great plate .

While some of these things might be suitable , in the full scheme of building a plated still , the plates are only minor part of the project and it is generally better to use a known hole size and grid pattern that has been proven to work .

So it depends on the the hole size and spacing whether your screens might work or not ....but there are also other points like leaving a small area around the curcumference and down comer areas where there should be no holes ...again , it better to start from scratch .

But don't loose the dream

.....I still wonder about those coffee strainers