Page 1 of 2

Simple is beautiful

Posted: Sun Feb 10, 2008 5:36 am

by Ripa

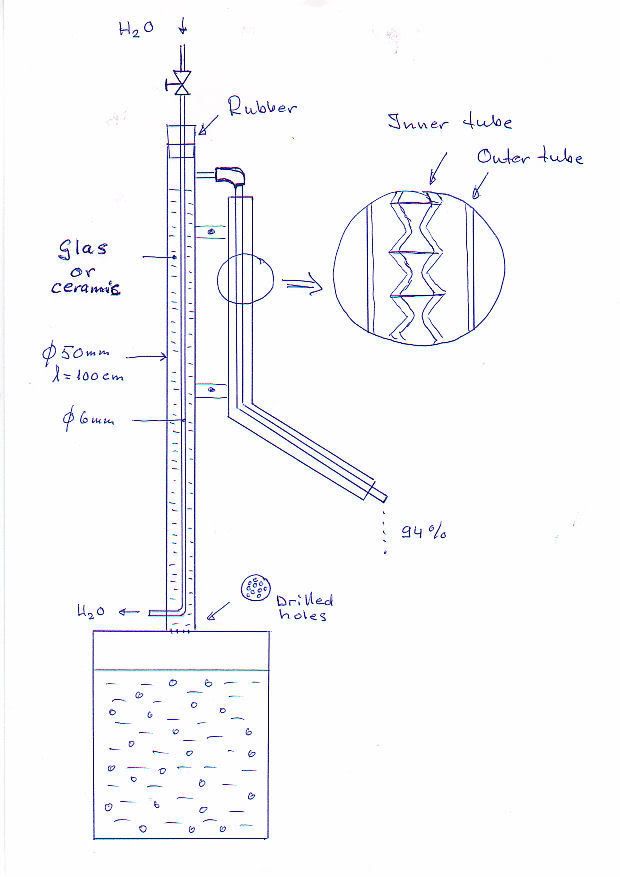

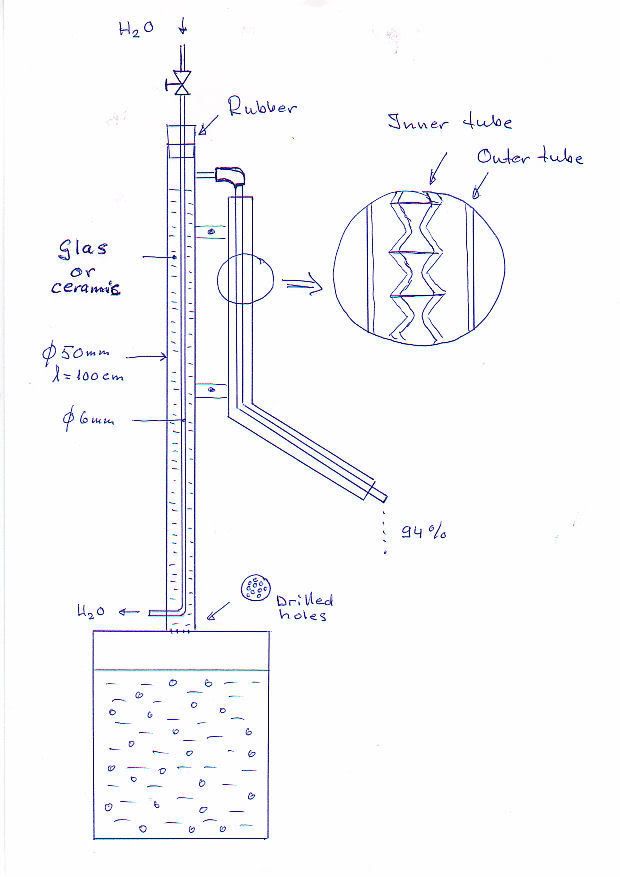

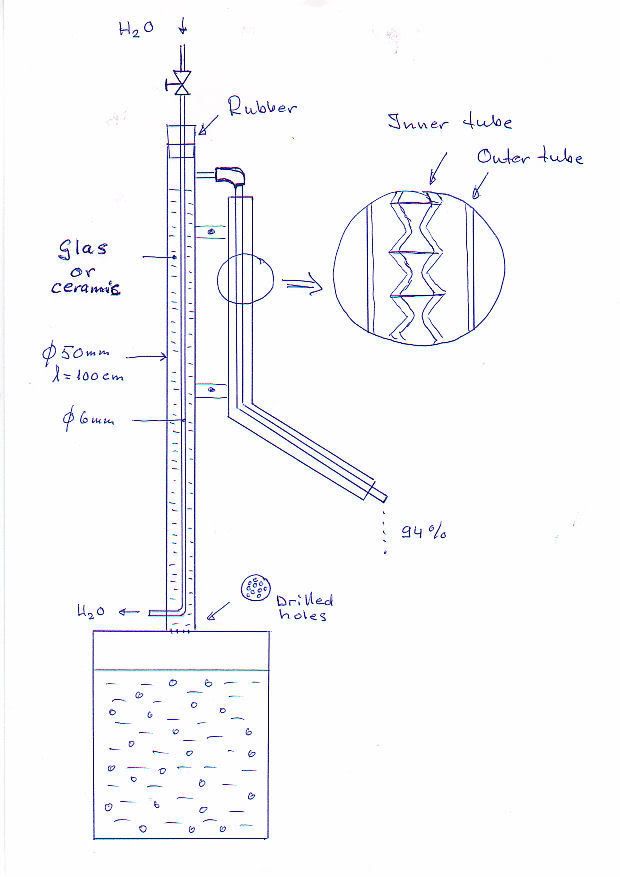

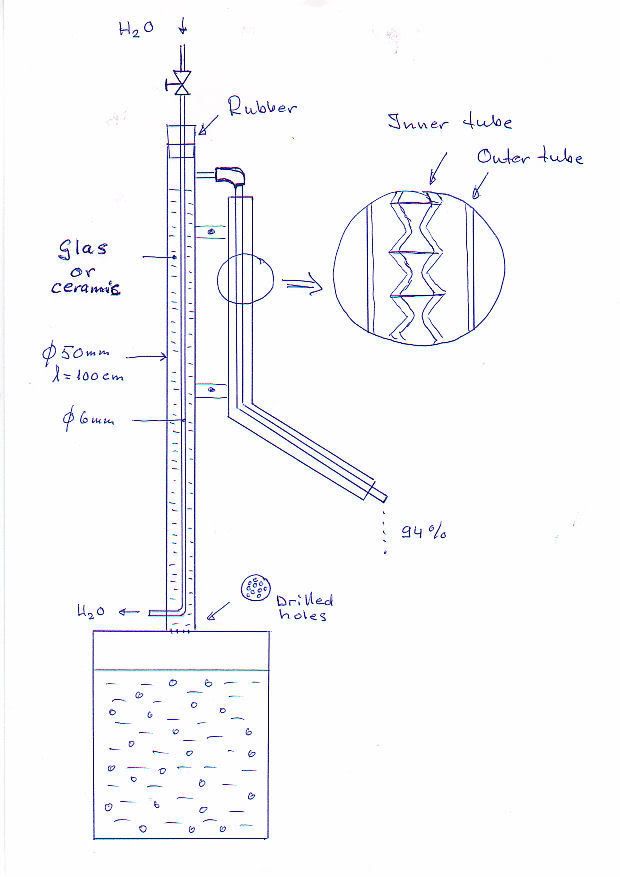

20 years ago I made a still, that needs no temperaturemeter and it stops automatically distilling, when there is no alcohol anymore

[/img]

Posted: Sun Feb 10, 2008 5:41 am

by As-Ol-Joe

Welcome to the forum.

Would you please explain in a little more detail how it stops automatically.

Posted: Sun Feb 10, 2008 6:01 am

by Ripa

Working principal is:

- Boiling energy must be sufficient and standard all the time

- Through the 6 mm tube must be flown cold water sufficiently when boiling is starting

- No alcohot must not flow out this time

- When boiling is standarded, cold water is regulated so, that alcohol is dropped, no by flowing or streaming, only dropping

- When there is anymore no alcohol, there is also not any dropping!

-That is the automiatic processing, and You need not any thermometer, only a need-valve.

Posted: Sun Feb 10, 2008 7:13 am

by Ripa

Details of the condensor:

- The inner tube of condensor is flattened in 90 degree directions as in the picture

- Do not flatten too much, there must be small hole inside!

- This is done for more flow resistance

- This makes condensing more efficient

Posted: Sun Feb 10, 2008 8:49 am

by big worm

looks like a long reflux column an early version.

Posted: Wed Feb 13, 2008 8:56 am

by manu de hanoi

the charles 803 also uses this kind of internal reflux cooling. I wonder about the efficiency .... Usually it is recommended to reflux on top of the column....

I wonder which alien technology lets your have an accordion tube like that.

Is there some water flow between the inner and outer tube to cool the vapors ?

Posted: Wed Feb 13, 2008 9:15 am

by rad14701

I was in Lowes last weekend and got a similar condenser idea while looking at those semi-rigid flexible copper hot water tank connect lines... While maybe not doing as much restricting there would be slightly more surface area and the spirals would slow the descent of condensed vapors, increasing thermal transfer... A bit of copper or stainless scrubber in the end would also help...

I'm not sure I fully understand the automatic theory described above, however... I just don't see how not using a thermometer or hydrometer would make the column useful for much other than stripping runs...

Posted: Sat Feb 16, 2008 8:05 am

by Ripa

Is this picture better to understation working principals?

How to make that accordion tube:

- Press the tube from one direction flattened

- Be careful not too much, there must be a little hole inside

- Turn the tube 90 degrees

- Repeat pressing from this direction

- Turn again 90 degrees and press the tube

- Repeat this so many times as nesessary

The flattenet tube makes more resistance of flow and makes condensing more effective.

This stil is made of stainless steel by solderin with silver. At first solderin was difficult, then I realised that stainless steel must not be warmed to red colour, only warm enough and put silver to joints.

I try to give a photo of this [/img]

Posted: Sat Feb 16, 2008 10:38 am

by BW Redneck

I don't like seein' the convoluted leibig condenser sloping down at an angle. Distillate can collect in those bumps and cut down on your cooling a bit. Plus, it's hard to get all of the distillate out. It's like having a worm with high spots in it.

Posted: Sat Feb 16, 2008 7:44 pm

by big worm

the surface area would be the same crimped or straight don't think it would matter on a condenser perhaps would build slight back pressure and hold vapor back a little , but doubt would be worth the extra effort...who knows? could be on sumting

Posted: Sat Feb 16, 2008 7:54 pm

by rad14701

big worm wrote:the surface area would be the same crimped or straight don't think it would matter on a condenser perhaps would build slight back pressure and hold vapor back a little , but doubt would be worth the extra effort...who knows? could be on sumting

The crimping would, just as I mentioned about the "ribbed" hot water tank hook-up lines, provide more cooling area per linear inch of condenser as well as slowing condensate from gaining too rapid downward flow rate... But I agree, it may or may not be worth the added labor or expense depending on the method used...

Posted: Sat Feb 16, 2008 7:54 pm

by Pikluk

im still bugged on the "it stop automatically"...

Posted: Sat Feb 16, 2008 7:55 pm

by rad14701

Pikluk wrote:im still bugged on the "it stop automatically"...

That makes two of us...

Posted: Sat Feb 16, 2008 9:27 pm

by new_moonshiner

was this for fuel ? or was rubber not a issue 20 years back .

Posted: Sun Feb 17, 2008 12:05 am

by HookLine

rad14701 wrote:Pikluk wrote:im still bugged on the "it stop automatically"...

That makes two of us...

Three of us.

Posted: Sun Feb 17, 2008 3:11 am

by Rudi

Looks to me like a variant of the internal reflux. Can't for the life of me see how that would be auto?

so that would make 4 of us

Be interested in more explaination of the auto stop Ripa

Posted: Sun Feb 17, 2008 11:48 am

by BW Redneck

I can understand how a VM outfit would stop collecting automatically, but not this. In a VM setup like Hook's, the vapor will eventually become the same density as air once most of the alcohol is run out of it. The vapor won't move to the side condenser because it is too light to sink.

Maybe I'm wrong, but I'm still a bit puzzled. Besides, having a cooling management system like that is still inferior to a vapor management model IMO.

Posted: Sun Feb 17, 2008 4:09 pm

by Pikluk

from the little experience i have with a tall reflux column, is when you achieve a equilibrium it stay stable until you have not much ethanol left in the boiler, then the temperature just start rising.

pretty sure a VW column would do the same.

Posted: Sun Feb 17, 2008 4:34 pm

by rad14701

The only way I can figure this setup to work without a way to monitor the process would be lucky at best... If you were to get the column stable for proper take-off and it was to remain stable, then, if the coolant flow was also stable, tails vapors would exit out the top of the column because there wouldn't be enough cooling in the column to knock them back down... I see a problem with this idea, however, because the diagrams show a rubber plug in the top of the column which would block the escape of overheated vapors... Just kicking theories around...

Posted: Sun Feb 17, 2008 5:13 pm

by HookLine

Pikluk wrote:a VW column would do the same.

I'd like to see that.

Posted: Sun Feb 17, 2008 6:43 pm

by BW Redneck

HookLine wrote:Pikluk wrote:a VW column would do the same.

I'd like to see that.

What, ya tryin'a make vodka with your 1969 Beetle or the Minibus ya had "back in the day?"

Posted: Sun Feb 17, 2008 6:50 pm

by Old_Blue

Specially modified inverted upside down inverse convoluted VM

Posted: Mon Feb 18, 2008 10:18 am

by Pikluk

hook even on the last 500ml of a 2.5gal low wine run the temp stay steady in your column?

Posted: Mon Feb 18, 2008 7:16 pm

by HookLine

No. The temp starts rising just before the end of the ethanol. But it only just starts rising. It is rock solid right up to that point (can vary ± 0.1C). When it consistently moves up just 0.1-0.2 C I know it is pretty well the end. I can slow down the take-off rate (ie up the reflux ratio) and collect a bit more, but there is so little left by then (and it is usually past midnight), that it isn't worth it. I don't even bother collecting the tails anymore on a reflux run.

Posted: Tue Feb 19, 2008 10:10 am

by Ripa

Here is the history of making this still:

I was looking when my father-in-law was trying to distill with very simple system. Next day I discussed with my older working fellow and he told that in his earlier workplace there was a man, who made a distilling system every evening after workdays. Then he got it ready. My fellow told me the name of the firm and the name of that man.

I phoned that man and told regards of my fellow and asked if he made distilling system. Yes, he made that. He told me in phone how to make this. First he had "Desti"- still, similiar as in first page of this forum. First he added tubes through the still, the more tubes, the better distilling. At last he put the smaller tube inside the bigger tube in same direction and regulated waterflow with needle valve.

Inside to column he advicet to put small ceramic tubes 90 % of high, same tubes, which are used in aquarium systems.

He told me, that it needs no temperature meter and it stops automatic, no alcohol, no dropping.

I made the still, as he told me, and gave it to mu father-in-law, and told him how to use it.

I myself never used that still, I only got good alcohol for present.

I also can tell how to use active carbon to delete smells if necessary, but if distilling is made enougn well, it is not necessary to use that.

This is what is told to me, and how I made the still. I can tell, that in the bottle there is no other smells than pure alcohol.

The foto is coming later.

Posted: Tue Feb 19, 2008 10:37 am

by kingearwig

so you are unconcerned about the giant rubber stopper?

Posted: Tue Feb 19, 2008 10:40 am

by rad14701

Ripa wrote:I also can tell how to use active carbon to delete smells if necessary, but if distilling is made enougn well, it is not necessary to use that.

While the additional description does help make some sense of things, the fact that carbon filtering is being used to remove smells would indicate that the still isn't really stopping auto-magically where it is assumed to be stopping... I think the pictures might help sort things further... I'm still a bit skeptical...

Posted: Thu Feb 21, 2008 3:13 am

by Ripa

kingearwig wrote:so you are unconcerned about the giant rubber stopper?

I don´t understand, what You are meaning.

My drawings show You, how it is easy to make a distilling system, that do not need any thermometer or electronic warm adjusting, only huge boiling and a simple cold water adjusting, the colon makes the rest.

What is needed to make this system:

1. Stainless tubes

- Diameter 50 mm x 100 cm

- Diameter 6 mm x 120 cm

- Diameter 16 mm x 80 cm

- Diameter 25 mm x 60 cm

2. Pressure kettle, or other boiling barrel about 10 litres

3. Metal shaw

4. Drilling machine

5. File

6. Screw press

7. Needle valve for 6 mm tube

8. Ceramic tubes diameter 10 mm x 16 mm

9. Rubber plug or other system for overpressure

10. Silicone tube for joining 16 mm tubes between still and condenser

11. Gas welding system, silver and suitable solvent

12. Unprejudiced mind

13. Some hours of work

Posted: Fri Feb 22, 2008 2:10 am

by manu de hanoi

perhaps there is a condition where the reflux lets some alcohol out but condensate all the water (because water is easier to condensate than alcohol).....at least for a period of time.

Posted: Fri Feb 22, 2008 4:17 am

by Pikluk

perhaps there is a condition where the reflux lets some alcohol out but condensate all the water (because water is easier to condensate than alcohol).....at least for a period of time.

that is the basic principal behind a reflux column...

ripa your design is not bad but since you made that column there a few people who had some great ideas...

you really want simple and beautiful then i got only one name for you bokakob.

the reflux line from your design could be more effective, if you cool stuff at the bottom of the column like in your design it makes it harder to get equilibrium.

bokakob design makes all the reflux at the top of the column, this give a lot more chance for the ethanol to actually reflux almost like a double boiler inside the column.

and theres no way that column will stop by itself, unless you got some power input control and a temp sensor.

VM column (not vw

took me two days to notice my typo...) are really simple and beautiful just more expensive then bokakob angle plate.