[/img]

Moderator: Site Moderator

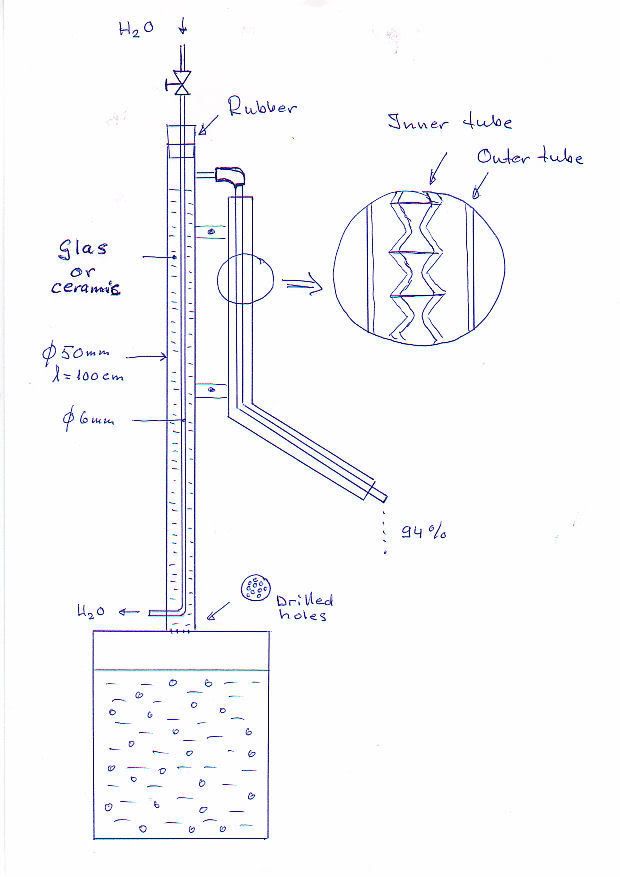

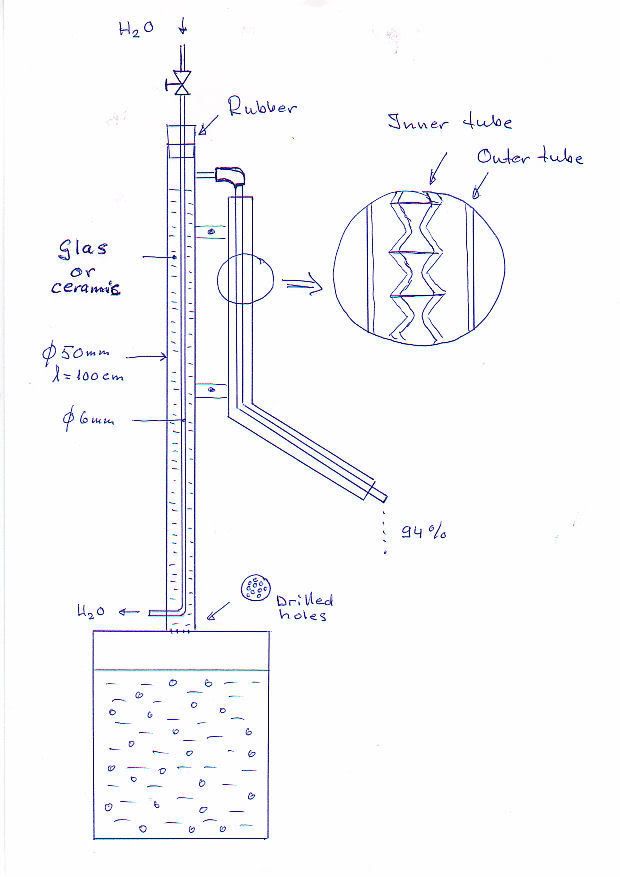

The crimping would, just as I mentioned about the "ribbed" hot water tank hook-up lines, provide more cooling area per linear inch of condenser as well as slowing condensate from gaining too rapid downward flow rate... But I agree, it may or may not be worth the added labor or expense depending on the method used...big worm wrote:the surface area would be the same crimped or straight don't think it would matter on a condenser perhaps would build slight back pressure and hold vapor back a little , but doubt would be worth the extra effort...who knows? could be on sumting

What, ya tryin'a make vodka with your 1969 Beetle or the Minibus ya had "back in the day?"HookLine wrote:I'd like to see that.Pikluk wrote:a VW column would do the same.

While the additional description does help make some sense of things, the fact that carbon filtering is being used to remove smells would indicate that the still isn't really stopping auto-magically where it is assumed to be stopping... I think the pictures might help sort things further... I'm still a bit skeptical...Ripa wrote:I also can tell how to use active carbon to delete smells if necessary, but if distilling is made enougn well, it is not necessary to use that.

I don´t understand, what You are meaning.kingearwig wrote:so you are unconcerned about the giant rubber stopper?

that is the basic principal behind a reflux column...perhaps there is a condition where the reflux lets some alcohol out but condensate all the water (because water is easier to condensate than alcohol).....at least for a period of time.