Page 1 of 2

Semi-Automatic Liquid Management

Posted: Wed Jul 13, 2022 11:26 am

by spiritdistiller123

Hello guys,

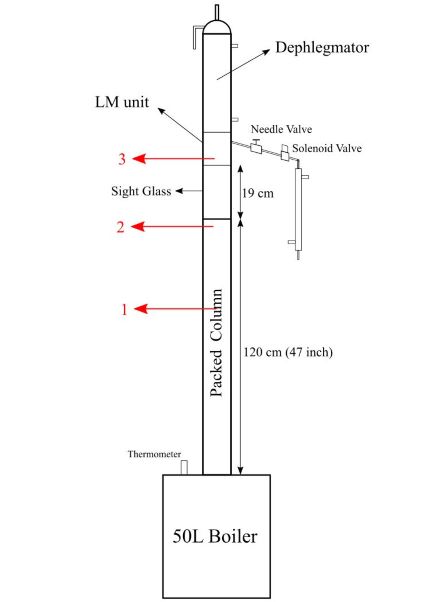

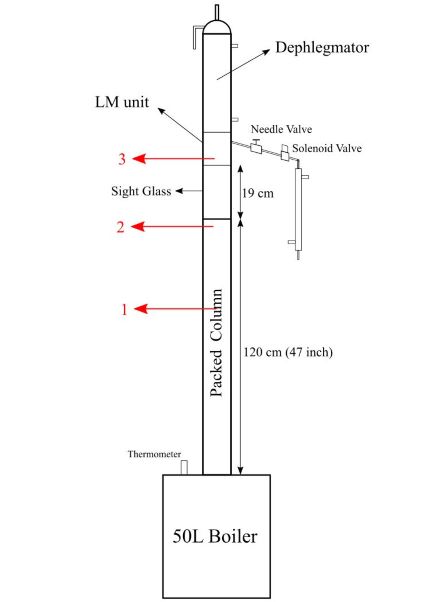

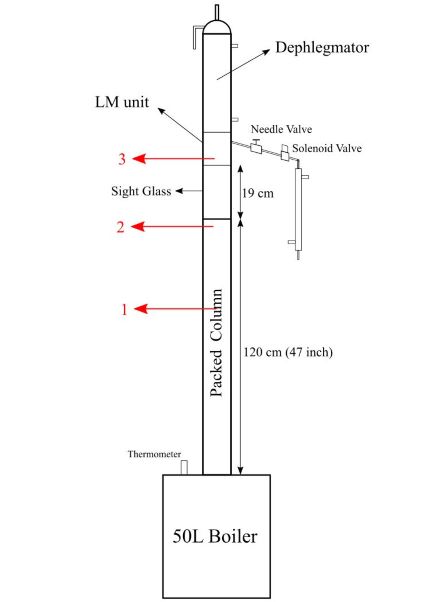

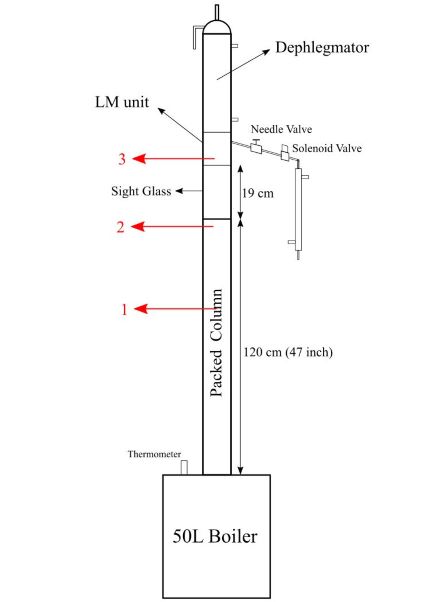

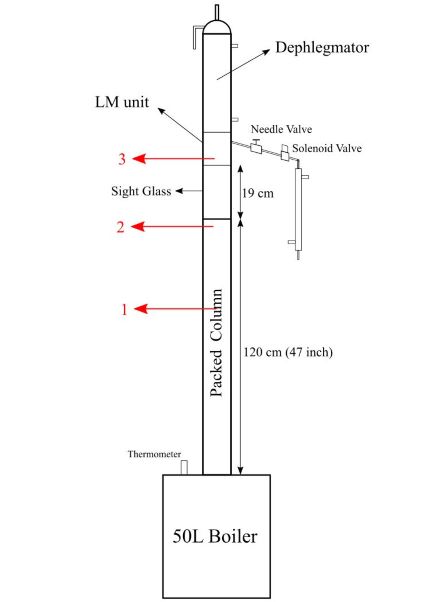

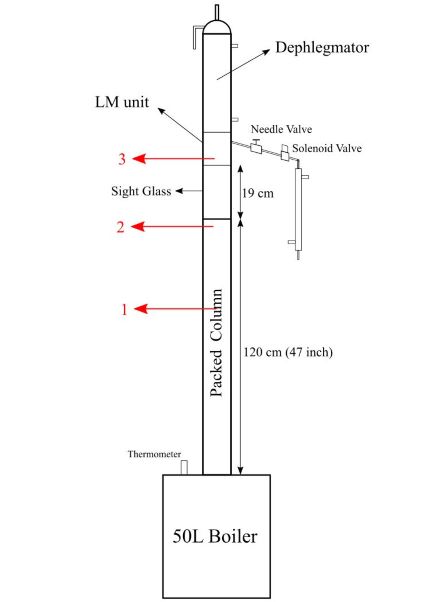

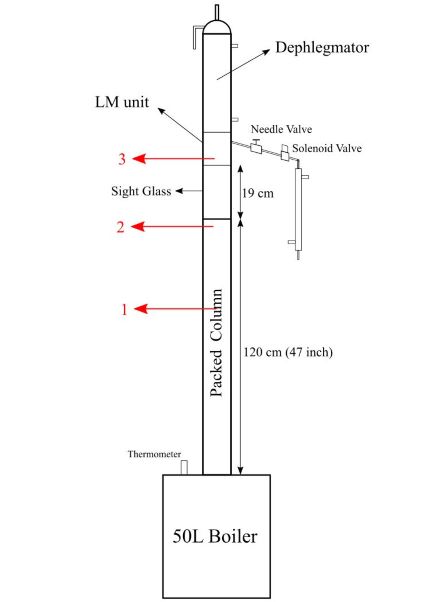

I have a liquid management column and I want to automate it.

My goal is to get a consistent 96% neutral.

My boiler capacity is about 50 Liter with a 4000-watt heater.

A 2 inches column with 47 inches (120 cm) height, packed with SPP, is installed on the boiler with a sight glass above it to observe the process

The liquid management unit (LMU) is located above the sight glass.

The LMU has a regulating stem needle valve. Similar to this:

https://products.swagelok.com/en/c/stra ... /p/SS-1RS4

After the needle valve, I want to install a solenoid valve. This one: Duravis ESV 620 (

http://www.us-kon.com.tr/en/productdeta ... s-820-1-43)

There is a control box with PID which is equipped with a PT1000 RTD sensor.

A schematic of the still is depicted in the below figure.

My first question is: where is the best place to locate the sensor probe for PID, I marked three places on the column with 1 , 2 and 3. My opinion is that 1st place is the best. Because the reflux is cool and 2 and 3 may show wrong temperatures. But in the 1st place, the reflux and vapor have some time to become isotherm (have the same temperature). Therefore, I think the first place is the best one to consider for the equilibrium in the column. Which place do you think is the best? 1,2,3 or even other places?

In my mind, the process is as follows:

* First the heater is adjusted to its maximum power to heat the wash.

* When the thermometer that is located above the boiler goes up ( about 60 C degrees), the operator will lower the power. (I think for my spp (3.5 x 3.5) and column ( 2 inches), it is about 1300 watts).

* The column tries to reach equilibrium after some time (between 30-45 min). Heads are removed manually at 3 drops per second rate.

* After the heads are collected the needle valve is closed.

* Azeo is reached and the temperature of the column ( 1? or 2? or 3?) is stable.

* The PID control is set to Azeo temp (let's say 78 C degrees). The solenoid valve is open when the temperature is 78. The needle valve is adjusted in such a way that does not disturb the equilibrium of the column. When the temperature goes above 78 ( for example 78.1 ) the solenoid valve is closed. After some full reflux, the Azeo is reached again and the valve will remain closed for some time (5-10min) in order to reach equilibrium again. Then the solenoid valve will be open again and this cycle continues until a small amount of alcohol remains in the boiler.

* Take-off rate is constant during heart collection. ( is it correct?)

* When there is successive closing and opening of the solenoid valve, the operator figures out that the heart collection is over.

* Tails are also collected manually.

So, as you can see only the collection of hearts is automated and this is why I called it Semi-Automatic LM.

What are the problems in my plan?

Any comments? Opinions? Improvements?

Re: Semi-Automatic Liquid Management

Posted: Wed Jul 13, 2022 12:56 pm

by Stonecutter

This dead horse

This topic can be quite contentious. I don’t want to come across as offensive, so I’ll just suggest you use the search icon in the top left and research a little bit before continuing on. Read read read and you’ll find the answers you’re looking for.

Cheers

Re: Semi-Automatic Liquid Management

Posted: Wed Jul 13, 2022 1:12 pm

by LWTCS

PID for cooling media flow rate control would pass muster.

Some type of preheat would fly.

What OP proposes is not really a worthy project if optimally distilled spirits is the goal.

Re: Semi-Automatic Liquid Management

Posted: Wed Jul 13, 2022 1:44 pm

by Saltbush Bill

spiritdistiller123 wrote: ↑Wed Jul 13, 2022 11:26 am

only the collection of hearts is automated and this is why I called it Semi-Automatic LM.

I'm afraid I don't really see the point of this, if a LM still such as a Boka is running correctly / with the right packing, there is hardly ever any reason to adjust the needle valve / flow leaving the still when in hearts anyway. A quick tweek at the very beginning maybe and another to slow take off at the very end when tails show......and only that if you really want to milk / squeeze that last small bit from the wash/ low wines.

Hardly worth the trouble is it ?

Re: Semi-Automatic Liquid Management

Posted: Wed Jul 13, 2022 1:51 pm

by shadylane

An LM is already good at maintaining a high ABV.

I'm thinking, trying to automate it by cycling the takeoff rate would just cause problems.

posting with salty

Re: Semi-Automatic Liquid Management

Posted: Wed Jul 13, 2022 2:37 pm

by Stonecutter

spiritdistiller123 wrote: ↑Wed Jul 13, 2022 11:26 am

Hello guys,

I have a liquid management column and I want to automate it.

My goal is to get a consistent 96% neutral.

My boiler capacity is about 50 Liter with a 4000-watt heater.

A 2 inches column with 47 inches (120 cm) height, packed with SPP, is installed on the boiler with a sight glass above it to observe the process

The liquid management unit (LMU) is located above the sight glass.

The LMU has a regulating stem needle valve. Similar to this:

https://products.swagelok.com/en/c/stra ... /p/SS-1RS4

After the needle valve, I want to install a solenoid valve. This one: Duravis ESV 620 (

http://www.us-kon.com.tr/en/productdeta ... s-820-1-43)

There is a control box with PID which is equipped with a PT1000 RTD sensor.

A schematic of the still is depicted in the below figure.

My first question is: where is the best place to locate the sensor probe for PID, I marked three places on the column with 1 , 2 and 3. My opinion is that 1st place is the best. Because the reflux is cool and 2 and 3 may show wrong temperatures. But in the 1st place, the reflux and vapor have some time to become isotherm (have the same temperature). Therefore, I think the first place is the best one to consider for the equilibrium in the column. Which place do you think is the best? 1,2,3 or even other places?

In my mind, the process is as follows:

* First the heater is adjusted to its maximum power to heat the wash.

* When the thermometer that is located above the boiler goes up ( about 60 C degrees), the operator will lower the power. (I think for my spp (3.5 x 3.5) and column ( 2 inches), it is about 1300 watts).

* The column tries to reach equilibrium after some time (between 30-45 min). Heads are removed manually at 3 drops per second rate.

* After the heads are collected the needle valve is closed.

* Azeo is reached and the temperature of the column ( 1? or 2? or 3?) is stable.

*

The PID control is set to Azeo temp (let's say 78 C degrees). The solenoid valve is open when the temperature is 78. The needle valve is adjusted in such a way that does not disturb the equilibrium of the column. When the temperature goes above 78 ( for example 78.1 ) the solenoid valve is closed. After some full reflux, the Azeo is reached again and the valve will remain closed for some time (5-10min) in order to reach equilibrium again. Then the solenoid valve will be open again and this cycle continues until a small amount of alcohol remains in the boiler.

* Take-off rate is constant during heart collection. ( is it correct?)

* When there is successive closing and opening of the solenoid valve, the operator figures out that the heart collection is over.

* Tails are also collected manually.

So, as you can see only the collection of hearts is automated and this is why I called it Semi-Automatic LM.

What are the problems in my plan?

Any comments? Opinions? Improvements?

Is there some physical factor that limits your ability to smell and taste for your cuts?

Us electric element guys are already spoiled

The Automatron guys are pretty slick. I’ve seen some true next level shit in the short amount of time I’ve been here. You sound like a fairly educated individual. Try it both ways and tell us how it went.

Re: Semi-Automatic Liquid Management

Posted: Thu Jul 14, 2022 3:36 am

by spiritdistiller123

I think that dead horse is about controlling the heater of boiler with PID. I want to control the take-off of LM with PID.

Stonecutter wrote: ↑Wed Jul 13, 2022 2:37 pm

Is there some physical factor that limits your ability to smell and taste for your cuts?

I always make my cuts using smell and taste.

Thanks anyway

Re: Semi-Automatic Liquid Management

Posted: Thu Jul 14, 2022 3:48 am

by spiritdistiller123

Saltbush Bill wrote: ↑Wed Jul 13, 2022 1:44 pm

I'm afraid I don't really see the point of this, if a LM still such as a Boka is running correctly / with the right packing, there is hardly ever any reason to adjust the needle valve / flow leaving the still when in hearts anyway. A quick tweek at the very beginning maybe and another to slow take off at the very end when tails show......and only that if you really want to milk / squeeze that last small bit from the wash/ low wines.

Hardly worth the trouble is it ?

Sometimes in distilling high-proof alcohol (96), it happened to me that the equilibrium of the column was disturbed and I had to close the valve and open it again. this usually happens at the end of hearts and sometimes in the middle due to different external or internal factors. So, the operator has to watch the thermometer above the column all the time to see that the equilibrium in maintained during the run. If the equilibrium is disturbed and the operator does not see that, then there is smeared alcohol in the product.

My main goal is to devise a way in order to prevent such things.

But I also think about its worthiness and feasibility and this is why I am seeking some advice

Re: Semi-Automatic Liquid Management

Posted: Thu Jul 14, 2022 4:02 am

by Rrmuf

Is there a safety issue with a valve on the outtake path? It seems to me that anything sophisticated that can restrict vapour flow is just a bad idea.

...I'm asking to understand why/what makes this safe as opposed to crapping all over the idea.

Re: Semi-Automatic Liquid Management

Posted: Thu Jul 14, 2022 4:18 am

by Yummyrum

Rrmuf wrote: ↑Thu Jul 14, 2022 4:02 am

Is there a safety issue with a valve on the outtake path? It seems to me that anything sophisticated that can restrict vapour flow is just a bad idea.

...I'm asking to understand why/what makes this safe as opposed to crapping all over the idea.

Rrmuf

Yeah it's safe . LM stills have a needle valve that can be shut off during equalisation .IE , the output path is shut off . When the Solenoid valve in the OP’s design is closed , it’s just like an LM in equalisation .

But just like any LM or VM still head , there must be a vent above the reflux condenser .

Re: Semi-Automatic Liquid Management

Posted: Thu Jul 14, 2022 4:33 am

by Rrmuf

Yummyrum wrote: ↑Thu Jul 14, 2022 4:18 am

Rrmuf wrote: ↑Thu Jul 14, 2022 4:02 am

Is there a safety issue with a valve on the outtake path? It seems to me that anything sophisticated that can restrict vapour flow is just a bad idea.

...I'm asking to understand why/what makes this safe as opposed to crapping all over the idea.

Rrmuf

Yeah it's safe . LM stills have a needle valve that can be shut off during equalisation .IE , the output path is shut off . When the Solenoid valve in the OP’s design is closed , it’s just like an LM in equalisation .

But just like any LM or VM still head , there must be a vent above the reflux condenser .

Thanks. I get it: My experience is with a CM still.

Re: Semi-Automatic Liquid Management

Posted: Thu Jul 14, 2022 4:35 am

by Yummyrum

I’ve been pondering this .

Will cycling between full reflux ( solenoid closed ) , and taking off product ( solenoid open ) upset the steady state in the column ?

I guess so long as the needle is set for a high reflux ratio , that it will be minimal . I would guess that at this point , the solenoid will be on more that it will be off .IE , the still will be running pretty much at optimum .

I think it’s an interesting project for projects sake , but I don’t think it would achieve much mire than a normally operated still will achieve .

My reasoning for saying that is that the automation will really only come into play when tails are near and seriously , if Azeo is the aim , then tails taint will already be present in the output before the thermometers can detect it .

Re: Semi-Automatic Liquid Management

Posted: Thu Jul 14, 2022 5:36 pm

by bluefish_dist

I think you could make it work, but I would make a reverse lm and have it slowly open the valve to reduce takeoff as the temperature climbs.

I have considered doing a similar setup with my vm still. Have it open the valve to start takeoff, then close it 1/2 turn anytime the temp hits my set point. Also put a time constant to allow the column to react to the change. Ie maybe 30-60 sec between adjustments. I did this by hand, so no reason it could not be automated.

Re: Semi-Automatic Liquid Management

Posted: Thu Jul 14, 2022 6:52 pm

by Stonecutter

spiritdistiller123 wrote: ↑Thu Jul 14, 2022 3:36 am

I think that dead horse is about controlling the heater of boiler with PID. I want to control the take-off of LM with PID.

I always make my cuts using smell and taste.

Thanks anyway

My point is that you’re talking about an “azeo vapor temperature” and using the movement of a solenoid being controlled by a thermometer somewhere in the vapor path to determine when to make a hearts cut.

I know little to nothing about the science behind Distilling but from what I’ve read I just don’t see the repeatability of such a system.

I do know that each run is only predictable to a certain degree and then the operator has to make a decision. If you’re only trying to get close with a PID to act as a kind of alarm then I can see some advantage to such a mechanism. Especially during large spirit runs. If I’m misunderstanding your intentions I apologize. I’ve already suggested you try it and let us know how it works. I’m not saying don’t do it. I’m a newbie to the hobby and I genuinely would like to see the results. I hope to be able to proceed a more scientific and informed opinion or suggestion in the future. I’m not trying to hijack your thread I’m just trying to join in on the convo.

Edit:I admit that initially I absolutely misunderstood your original post and my first response was unwarranted.

Re: Semi-Automatic Liquid Management

Posted: Thu Jul 14, 2022 7:16 pm

by shadylane

Yummyrum wrote: ↑Thu Jul 14, 2022 4:35 am

My reasoning for saying that is that the automation will really only come into play when tails are near and seriously , if Azeo is the aim , then tails taint will already be present in the output before the thermometers can detect it .

+1

My 2 cents.

Using vapor temp to measure ABV has one major drawback. That's thermometer error.

Even a fraction of a degree error makes a difference when trying for azeo.

Here's a thought for folks that want to automate based on temps.

Do a water run with the reflux still and see how far off the vapor temp measurement is from 100c.

Re: Semi-Automatic Liquid Management

Posted: Fri Jul 15, 2022 4:55 am

by bluefish_dist

If you account for pressure using vapor temp to control abv is quite effective. Even if not accounting for pressure and just using a new temperature based on that days run is pretty effective. It will change about 1 deg depending on atmospheric pressure. I only got burned once when a front moved in during the day. Would have easily been avoidable with a few more abv checks, even the. It was only a .3 proof difference.

Note I said abv, not anything about cuts as I can do my whole run at the same abv. Yes, all the cuts can come over at the same abv depending on how you run your still. Temperature on a column still is useful, just don’t use it to try and do something it won’t do.

Re: Semi-Automatic Liquid Management

Posted: Sun Jul 17, 2022 8:04 am

by bunny

spiritdistiller123 wrote: ↑Wed Jul 13, 2022 11:26 am

Hello guys,

I have a liquid management column and I want to automate it.

My goal is to get a consistent 96% neutral.

My boiler capacity is about 50 Liter with a 4000-watt heater.

A 2 inches column with 47 inches (120 cm) height, packed with SPP, is installed on the boiler with a sight glass above it to observe the process

The liquid management unit (LMU) is located above the sight glass.

The LMU has a regulating stem needle valve. Similar to this:

https://products.swagelok.com/en/c/stra ... /p/SS-1RS4

After the needle valve, I want to install a solenoid valve. This one: Duravis ESV 620 (

http://www.us-kon.com.tr/en/productdeta ... s-820-1-43)

There is a control box with PID which is equipped with a PT1000 RTD sensor.

A schematic of the still is depicted in the below figure.

My first question is: where is the best place to locate the sensor probe for PID, I marked three places on the column with 1 , 2 and 3. My opinion is that 1st place is the best. Because the reflux is cool and 2 and 3 may show wrong temperatures. But in the 1st place, the reflux and vapor have some time to become isotherm (have the same temperature). Therefore, I think the first place is the best one to consider for the equilibrium in the column. Which place do you think is the best? 1,2,3 or even other places?

In my mind, the process is as follows:

* First the heater is adjusted to its maximum power to heat the wash.

* When the thermometer that is located above the boiler goes up ( about 60 C degrees), the operator will lower the power. (I think for my spp (3.5 x 3.5) and column ( 2 inches), it is about 1300 watts).

* The column tries to reach equilibrium after some time (between 30-45 min). Heads are removed manually at 3 drops per second rate.

* After the heads are collected the needle valve is closed.

* Azeo is reached and the temperature of the column ( 1? or 2? or 3?) is stable.

* The PID control is set to Azeo temp (let's say 78 C degrees). The solenoid valve is open when the temperature is 78. The needle valve is adjusted in such a way that does not disturb the equilibrium of the column. When the temperature goes above 78 ( for example 78.1 ) the solenoid valve is closed. After some full reflux, the Azeo is reached again and the valve will remain closed for some time (5-10min) in order to reach equilibrium again. Then the solenoid valve will be open again and this cycle continues until a small amount of alcohol remains in the boiler.

* Take-off rate is constant during heart collection. ( is it correct?)

* When there is successive closing and opening of the solenoid valve, the operator figures out that the heart collection is over.

* Tails are also collected manually.

So, as you can see only the collection of hearts is automated and this is why I called it Semi-Automatic LM.

What are the problems in my plan?

Any comments? Opinions? Improvements?

Hi SD123!

We have somewhat similar columns.

- image.jpeg (51.39 KiB) Viewed 1903 times

You should be able to see two thermometers sticking out the side.

For your project I would place your probe similar to my bottom thermometer, about 4-6 inches up from the bottom of the column. This would equate to about minus2 on your drawing.

When i run this, the boiler heats up and eventually starts sending vapor up the column. Typically that thermometer is around ambient until then and now jumps to the vapor temp in the top of the boiler which relates to the charge %. Mine usually spikes to around 185f or so and pretty much stays there until the reflux finally makes it's way back down to the boiler. The vapor continues up the column and spikes the upper thermometer. Now it pops through the top of the packing and spikes the very top thermometer for just a few seconds (if you're not watching, you will miss this) until the vapor is condensed and starts it return trip to the boiler. The top thermometer quickly drops to the BP of the current

distillate vapor which is typically less than the etoh azeo temp. I can watch the temp ease it's way back down until my upper thermometer is about 172-174f and the bottom thermometer is about 173-175f depending on the barometer.

Right or wrong I consider these temps define equilibrium for my column. Now I take fores and heads at 120ml/hr.

Typically those temps don't budge until tails start there way up the column. This is indicated by a spike in bottom temp and the end of my run. I don't try to nurse any more from what little that's left.

If you don't mind, I have a number of questions i would like to ask to compare with my rig.

I'm not using a controller. I do have two boilers with slightly different size elements. I can do 100% reflux with either somewhere between 1300 an 1400w (After a voltage drop from 120 to about 115 due to local conditions.)

Can you do 100% reflux at 1300w? How do you measure that wattage?

Have you measured your distillate volume at 0% reflux while using 1300w?

I'm getting about 5.6l/hr with a 40% boiler charge.

What signs tell you, that you have reached equilibrium?

Thanks,

I probably have more questions, but I'll just hold them for now.

Re: Semi-Automatic Liquid Management

Posted: Mon Jul 18, 2022 7:45 pm

by drmiller100

Some thoughts. NEVER make a bomb. Leave something past the top reflux open to the atmosphere.

Second, pot reflux stills are not constant. You can pull product off a LOT faster at the beginning of the run than the end of the run, which means you have to slow down the product pull as you go.

What IS constant is how much reflux your still requires. Rather than monitor how much product you pull you should monitor and manage the reflux going back down. Take the rest as product.

Third, the temperature to measure is 3 or 4 inches down in your packing. Full reflux to begin with. Pull the fores.

Then pull product, or manage reflux by the temperature I say. 4 inches down will be like 173. That gives you buffer to smooth out the hysteresis of adjusting your reflux.

Manage the temp 4 inches down and you can pull at most efficient speed.

Re: Semi-Automatic Liquid Management

Posted: Mon Jul 18, 2022 7:52 pm

by drmiller100

bunny wrote: ↑Sun Jul 17, 2022 8:04 am

spiritdistiller123 wrote: ↑Wed Jul 13, 2022 11:26 am

Hello guys,

I have a liquid management column and I want to automate it.

My goal is to get a consistent 96% neutral.

My boiler capacity is about 50 Liter with a 4000-watt heater.

A 2 inches column with 47 inches (120 cm) height, packed with SPP, is installed on the boiler with a sight glass above it to observe the process

The liquid management unit (LMU) is located above the sight glass.

The LMU has a regulating stem needle valve. Similar to this:

https://products.swagelok.com/en/c/stra ... /p/SS-1RS4

After the needle valve, I want to install a solenoid valve. This one: Duravis ESV 620 (

http://www.us-kon.com.tr/en/productdeta ... s-820-1-43)

There is a control box with PID which is equipped with a PT1000 RTD sensor.

A schematic of the still is depicted in the below figure.

My first question is: where is the best place to locate the sensor probe for PID, I marked three places on the column with 1 , 2 and 3. My opinion is that 1st place is the best. Because the reflux is cool and 2 and 3 may show wrong temperatures. But in the 1st place, the reflux and vapor have some time to become isotherm (have the same temperature). Therefore, I think the first place is the best one to consider for the equilibrium in the column. Which place do you think is the best? 1,2,3 or even other places?

In my mind, the process is as follows:

* First the heater is adjusted to its maximum power to heat the wash.

* When the thermometer that is located above the boiler goes up ( about 60 C degrees), the operator will lower the power. (I think for my spp (3.5 x 3.5) and column ( 2 inches), it is about 1300 watts).

* The column tries to reach equilibrium after some time (between 30-45 min). Heads are removed manually at 3 drops per second rate.

* After the heads are collected the needle valve is closed.

* Azeo is reached and the temperature of the column ( 1? or 2? or 3?) is stable.

* The PID control is set to Azeo temp (let's say 78 C degrees). The solenoid valve is open when the temperature is 78. The needle valve is adjusted in such a way that does not disturb the equilibrium of the column. When the temperature goes above 78 ( for example 78.1 ) the solenoid valve is closed. After some full reflux, the Azeo is reached again and the valve will remain closed for some time (5-10min) in order to reach equilibrium again. Then the solenoid valve will be open again and this cycle continues until a small amount of alcohol remains in the boiler.

* Take-off rate is constant during heart collection. ( is it correct?)

* When there is successive closing and opening of the solenoid valve, the operator figures out that the heart collection is over.

* Tails are also collected manually.

So, as you can see only the collection of hearts is automated and this is why I called it Semi-Automatic LM.

What are the problems in my plan?

Any comments? Opinions? Improvements?

Hi SD123!

We have somewhat similar columns.

image.jpeg

You should be able to see two thermometers sticking out the side.

For your project I would place your probe similar to my bottom thermometer, about 4-6 inches up from the bottom of the column. This would equate to about minus2 on your drawing.

When i run this, the boiler heats up and eventually starts sending vapor up the column. Typically that thermometer is around ambient until then and now jumps to the vapor temp in the top of the boiler which relates to the charge %. Mine usually spikes to around 185f or so and pretty much stays there until the reflux finally makes it's way back down to the boiler. The vapor continues up the column and spikes the upper thermometer. Now it pops through the top of the packing and spikes the very top thermometer for just a few seconds until the vapor is condensed and starts it return trip to the boiler. The top thermometer quickly drops to the BP of the current distillate which is typically less than the etoh azeo temp. I can watch the temp ease it's way back down until my upper thermometer is about 172-174f and the bottom thermometer is about 173-175f depending on the barometer.

Right or wrong I consider these temps define equilibrium for my column. Now I take fores and heads at 120ml/hr.

Typically those temps don't budge until tails start there way up the column. This is indicated by a spike in bottom temp and the end of my run. I don't try to nurse any more from what little that's left.

If you don't mind, I have a number of questions i would like to ask to compare with my rig.

I'm not using a controller. I do have two boilers with slightly different size elements. I can do 100% reflux with either somewhere between 1300 an 1400w (After a voltage drop from 120 to about 115 due to local conditions.)

Can you do 100% reflux at 1300w? How do you measure that wattage?

Have you measured your distillate volume at 0% reflux while using 1300w?

I'm getting about 5.6l/hr with a 40% boiler charge.

What signs tell you, that you have reached equilibrium?

Thanks,

I probably have more questions, but I'll just hold them for now.

Great questions from someone DOING IT!!!!!

You are exactly right about warm up. Very few actually have seen and felt the warm up on reflux column.

In first warm up, At full reflux, I can see Temps below 172. 170 is doable. Throw that stuff away. Sometimes I turn off my cooling water and watch 20 seconds go out the end.

Then let it stabilize at full reflux. This is your 190 neutral with a decent column. Barometric pressure will mess with the measured temperature, and this changes daily. But that is today's temp.

I can run 2000 watts through a 2 inch column but I sure as heck don't insulate it and I run 36 inches or more of 12 mm marbles.

Scrubbies I would guess would flood at that rate.

Re: Semi-Automatic Liquid Management

Posted: Tue Jul 19, 2022 8:49 am

by bunny

I'm having difficulty understanding your POVdrmiller100 wrote: ↑Mon Jul 18, 2022 7:45 pm

Some thoughts. NEVER make a bomb. Leave something past the top reflux open to the atmosphere.

Second, pot reflux stills are not constant. You can pull product off a LOT faster at the beginning of the run than the end of the run, which means you have to slow down the product pull as you go.

Efficiency is not on the top of my list. I'm currently running at a 10 to 1 RR. Start slow, Stay slow. When it's done, it's done.

What IS constant is how much reflux your still requires.

How do You determine that? Rather than monitor how much product you pull you should monitor and manage the reflux going back down. Take the rest as product.

Can You do this with any other method than LM?

Third, the temperature to measure is 3 or 4 inches down in your packing. Full reflux to begin with. Pull the fores.

No mention of heads between the fores and product?

Then pull product, or manage reflux by the temperature I say. 4 inches down will be like 173. That gives you buffer to smooth out the hysteresis of adjusting your reflux.

Manage the temp 4 inches down and you can pull at most efficient speed.

How do YOU manage the temperature? I can only manage RR and takeoff speed.

Re: Semi-Automatic Liquid Management

Posted: Tue Jul 19, 2022 8:51 am

by bunny

Some more I need help with:drmiller100 wrote: ↑Mon Jul 18, 2022 7:52 pm

Great questions from someone DOING IT!!!!!

You are exactly right about warm up. Very few actually have seen and felt the warm up on reflux column.

In first warm up, At full reflux, I can see Temps below 172. 170 is doable. Throw that stuff away. Sometimes I turn off my cooling water and watch 20 seconds go out the end.

So, YOU just vent VOCs instead of collecting them?

Then let it stabilize at full reflux. This is your 190 neutral with a decent column.

What makes YOU think this is 190 neutral? It may have an azeo temp, but if it's full of heads it's not neutral. Barometric pressure will mess with the measured temperature, and this changes daily.

(continuously) But that is today's temp.

I can run 2000 watts through a 2 inch column but I sure as heck don't insulate it

Why not? and I run 36 inches or more of 12 mm marbles.

What do you calculate the HETP of your marbles at? No guessing please.

Scrubbies I would guess would flood at that rate.

Please don't guess, only tell us what YOU believe to be true.

Re: Semi-Automatic Liquid Management

Posted: Tue Jul 19, 2022 4:50 pm

by drmiller100

bunny wrote: ↑Tue Jul 19, 2022 8:49 am

I'm having difficulty understanding your POVdrmiller100 wrote: ↑Mon Jul 18, 2022 7:45 pm

Some thoughts. NEVER make a bomb. Leave something past the top reflux open to the atmosphere.

Second, pot reflux stills are not constant. You can pull product off a LOT faster at the beginning of the run than the end of the run, which means you have to slow down the product pull as you go.

Efficiency is not on the top of my list. I'm currently running at a 10 to 1 RR. Start slow, Stay slow. When it's done, it's done.

What IS constant is how much reflux your still requires.

How do You determine that? Rather than monitor how much product you pull you should monitor and manage the reflux going back down. Take the rest as product.

Can You do this with any other method than LM?

Third, the temperature to measure is 3 or 4 inches down in your packing. Full reflux to begin with. Pull the fores.

No mention of heads between the fores and product?

Then pull product, or manage reflux by the temperature I say. 4 inches down will be like 173. That gives you buffer to smooth out the hysteresis of adjusting your reflux.

Manage the temp 4 inches down and you can pull at most efficient speed.

How do YOU manage the temperature? I can only manage RR and takeoff speed.

If you run full reflux you get no product. If you no reflux your column isn't going to make neutral. You enjoy watching 10 to 1 reflux. Ok.

If you pull product too fast you won't see 190 proof. You know this because the temperature rises above the magic temp of the day. I thought this was pretty basic stuff????

I struggle to keep up with some of the truths here. I thought fores and heads are the same thing here? If I'm using a pot reflux and I start with full reflux there is nasty stuff at the top (not to be confused with methanol, right???).

You throw that stiff away..

2000 watts on a 2 inch packed column is on the edge of too much heat. Leaving it uninsulated loses a bit of heat.

I don't care about hetp. 36 inches of marbles is enough to go from 3 percent to 95 percent. 24 inches is not. You have to substantially slow down product pull for 3 perce nt. 48 inches is also plenty but 48 inches is no faster than 36.

How many times does the liquid/fluid exchange happen? 25? 30? There is a calculator somewhere that tells you how many it takes. And 36 inches of 12 mm marbles shows something like 75 layers.

My continuous still has a lot more. It drives the beer well below 1 percent. I know this as the water boils at 212 (or whatever the magic water boiling temp is that day)

Anything can be used as packing. Some things are better than others depending on what you are doing.

I'm only concerned about neutral as fast as I can from 3 percent or better. Yes, pull rate from 3 percent is VERY slow.

Re: Semi-Automatic Liquid Management

Posted: Tue Jul 19, 2022 5:02 pm

by drmiller100

bunny wrote: ↑Tue Jul 19, 2022 8:51 am

Some more I need help with:drmiller100 wrote: ↑Mon Jul 18, 2022 7:52 pm

Great questions from someone DOING IT!!!!!

You are exactly right about warm up. Very few actually have seen and felt the warm up on reflux column.

In first warm up, At full reflux, I can see Temps below 172. 170 is doable. Throw that stuff away. Sometimes I turn off my cooling water and watch 20 seconds go out the end.

So, YOU just vent VOCs instead of collecting them?

Then let it stabilize at full reflux. This is your 190 neutral with a decent column.

What makes YOU think this is 190 neutral? It may have an azeo temp, but if it's full of heads it's not neutral. Barometric pressure will mess with the measured temperature, and this changes daily.

(continuously) But that is today's temp.

I can run 2000 watts through a 2 inch column but I sure as heck don't insulate it

Why not? and I run 36 inches or more of 12 mm marbles.

What do you calculate the HETP of your marbles at? No guessing please.

Scrubbies I would guess would flood at that rate.

Please don't guess, only tell us what YOU believe to be true.

I've been known to vent vocs. And I poop and pee also.

<Scrubbies I would guess would flood at that rate.>

>>>>Please don't guess, only tell us what YOU believe to be true

Your comment makes no sense. I told you my guess. I qualified my statement as a guess. I BELIEVE my guess to be true but I won't be totally shocked if I'm wrong.

Perhaps a language barrier????.

Re: Semi-Automatic Liquid Management

Posted: Tue Jul 19, 2022 5:24 pm

by drmiller100

Let's say you have a 5 gallon 10 percent in your boiler. You have a GOOD reflux column on top.

Now let's look at your reflux condenser. I'm assuming your still is similar to your picture.

Let's say your still holds 4 tablespoons of reflux fluid not including stuff in the column. This includes puddles, liquid on the condenser walls, in the pipe before the reflux valve.

Let's say there is about 1/4 cup of fores nasties in the 5 gallons of beer. If you run full reflux for 20 minutes the vast majority of those fores will be at the top of the column

Me, I make a HARD PULL, no reflux and try to get as much of that crap out at once. Full reflux, let it settle, maybe do it again. Or, I turn off cooling water and the nasties head out into my very well ventilated work space.

Venting is by far rhe most efficient. The fores want out and will leave, generally ahead of most of the etoh as the forest are obviously more volatile

On the other hand, you spend a long time mixing your good hearts with your fores drip by painful drip. Your still mixes the fores with the hearts giving you "heads "

I don't want heads. I want the fores out. I want the 190 as fast as I can. I don't want tails.

Re: Semi-Automatic Liquid Management

Posted: Tue Jul 19, 2022 5:42 pm

by richard1

Just for quick info in running a LM still, below is a photo of the screen showing temperatures during last stages of heat up up to where fores and heads are about to be stacked. If you are doing a spirit run, best is to stack the heads for at least +20 minutes in full reflux. Never turn water off to the the RC otherwise you will have unwanted vapours in the room as this is considered dangerous.

Re: Semi-Automatic Liquid Management

Posted: Tue Jul 19, 2022 5:54 pm

by richard1

A comment was raised above where it was queried how much KW you were throwing at your boiler at any one time. This is an easy one for a home distiller where you can get a meter from your electronics shop and wire it up with your controller. Here is a photo of my controller where I have variable control 0 - 5.5 KW.

Re: Semi-Automatic Liquid Management

Posted: Tue Jul 19, 2022 6:51 pm

by drmiller100

spiritdistiller123 wrote: ↑Wed Jul 13, 2022 11:26 am

Hello guys,

I have a liquid management column and I want to automate it.

My goal is to get a consistent 96% neutral.

My boiler capacity is about 50 Liter with a 4000-watt heater.

A 2 inches column with 47 inches (120 cm) height, packed with SPP, is installed on the boiler with a sight glass above it to observe the process

The liquid management unit (LMU) is located above the sight glass.

The LMU has a regulating stem needle valve. Similar to this:

https://products.swagelok.com/en/c/stra ... /p/SS-1RS4

After the needle valve, I want to install a solenoid valve. This one: Duravis ESV 620 (

http://www.us-kon.com.tr/en/productdeta ... s-820-1-43)

There is a control box with PID which is equipped with a PT1000 RTD sensor.

A schematic of the still is depicted in the below figure.

My first question is: where is the best place to locate the sensor probe for PID, I marked three places on the column with 1 , 2 and 3. My opinion is that 1st place is the best. Because the reflux is cool and 2 and 3 may show wrong temperatures. But in the 1st place, the reflux and vapor have some time to become isotherm (have the same temperature). Therefore, I think the first place is the best one to consider for the equilibrium in the column. Which place do you think is the best? 1,2,3 or even other places?

In my mind, the process is as follows:

* First the heater is adjusted to its maximum power to heat the wash.

* When the thermometer that is located above the boiler goes up ( about 60 C degrees), the operator will lower the power. (I think for my spp (3.5 x 3.5) and column ( 2 inches), it is about 1300 watts).

* The column tries to reach equilibrium after some time (between 30-45 min). Heads are removed manually at 3 drops per second rate.

* After the heads are collected the needle valve is closed.

* Azeo is reached and the temperature of the column ( 1? or 2? or 3?) is stable.

* The PID control is set to Azeo temp (let's say 78 C degrees). The solenoid valve is open when the temperature is 78. The needle valve is adjusted in such a way that does not disturb the equilibrium of the column. When the temperature goes above 78 ( for example 78.1 ) the solenoid valve is closed. After some full reflux, the Azeo is reached again and the valve will remain closed for some time (5-10min) in order to reach equilibrium again. Then the solenoid valve will be open again and this cycle continues until a small amount of alcohol remains in the boiler.

* Take-off rate is constant during heart collection. ( is it correct?)

* When there is successive closing and opening of the solenoid valve, the operator figures out that the heart collection is over.

* Tails are also collected manually.

So, as you can see only the collection of hearts is automated and this is why I called it Semi-Automatic LM.

What are the problems in my plan?

Any comments? Opinions? Improvements?

You MUST have a probe at 3 measuring vapor.

I'd put the sample probe 4 inches from the top of the packing. This will limit hysteresis.

I'd tune it so your sample probe is trying to get just under azeo.

My testing found yo yo ing like your planned algorithm is not the most efficient. You want to pull product consistently and let the column do its job.

So I'd suggest getting more complicated with your algorithm. Something like guess 2/3 (.66) of the time send reflux back down the column. If temp is above target add 5 points to reflux (.71).

If temp is too low subtract 5. Wait 10 seconds. Repeat

Take off rate is NOT constant. As you boil there is less etoh in the beer and alcohol comes out slower.

Re: Semi-Automatic Liquid Management

Posted: Wed Jul 20, 2022 5:54 am

by StillerBoy

spiritdistiller123 wrote: ↑Thu Jul 14, 2022 3:48 am

ometimes in distilling high-proof alcohol (96), it happened to me that the equilibrium of the column was disturbed and I had to close the valve and open it again. this usually happens at the end of hearts and sometimes in the middle due to different external or internal factors. So, the operator has to watch the thermometer above the column all the time to see that the equilibrium in maintained during the run. If the equilibrium is disturbed and the operator does not see that, then there is smeared alcohol in the product.

My main goal is to devise a way in order to prevent such things.

But I also think about its worthiness and feasibility and this is why I am seeking some advice

The issue that you are experiencing is due to lack of understanding of what is taking place during a reflux spirit run, and the main problem is not understanding take off rate in relation to it throughout the run, and there's no need for installing a solenoid valve in the take of line..

My unit run in semi automatic state, if you want to call it such, as it's very stable throughout the run.. the link to a thread where my setup is outlined should provide some further understanding.. (it was posted in a PID thread to show the different in requirement between the two)

viewtopic.php?f=85&t=77252&p=7592584#p7592584

Mars

Re: Semi-Automatic Liquid Management

Posted: Thu Jul 28, 2022 7:20 pm

by The Baker

I think I am glad I only run a pot still.

Geoff

Re: Semi-Automatic Liquid Management

Posted: Fri Jul 29, 2022 2:18 am

by Yummyrum

I dunno .

Just use a VM still head . Not effected by power fluctuations . Maintains constant Reflux ratio .

So much less hassle than trying to automate an LM still head that by its very nature has several demanding variables .

I think the best automated still would be one that sticks a tongue under the spout every few hundred mls and makes a decision on what to do next based on that .

Wait ….. I’m a computer

( OK , I an advanced model that adds water to the sample before placing on tongue sensor )