Page 1 of 1

Grain versus Potential Alcohol

Posted: Fri Jan 17, 2025 8:35 am

by Mr_Beer

My goal is to make reasonable tasting spirits from grains and other material sourced from the local feed store (in America).

I have had some different results with the actual distilled spirit available -- seemed to vary a lot. In particular, wheat whiskey seemed to offer lower yields than other grains and I liked the results (taste) a lot but the yield was low.

I did a little research and some computations. Here is what I came up with. No absolute truth here but a notion of potential yields based on grain type and various water amounts. It might help you as you develop your recipes.

These data were obtained by a series of recipe calculations at

https://www.brewersfriend.com/homebrew/ ... lculator

The grain selected was representative of raw, unmalted grain if possible.

Obviously Molasses is not a grain but included here for comparison purposes. They are intended to indicate the alcohol potential based on type of grain.

15 Gallon fermenter -- i.e. the amount of water available

Alcohol 'Index' based on grain

Molasses 2.08

Rye 1.27

Barley 1.10

Oats 1.13

Corn 1

Wheat 1.33

Millet 0.83

Molasses

35# 10.75%

40# 12.29%

45# 13.82%

50# 15.35%

Rye

35# 6.55%

40# 7.48%

45# 8.42%

50# 9.35%

Barley

35# 5.68%

40# 6.50%

45# 7.31%

50# 8.12%

Oats

35# 5.86%

40# 6.69%

45# 7.53%

50# 8.37%

Corn

35# 5.17%

40# 5.90%

45# 6.64%

50# 7.38%

Wheat

35# 6.55%

40# 7.481%

45# 8.410%

50# 9.35%

Millet

35# 4.32%

40# 4.92%

45# 5.54%

50# 6.15%

Re: Grain versus Potential Alcohol

Posted: Fri Jan 17, 2025 10:30 am

by Homebrewer11777

I've played around with adapting beer brewing calculators for these types of calculations and run into issues as none of the calculators I've used imagine fermenting on the grain.

So when you say your fermentor size determines how much water is available...I'd say not so fast. In my 30 gallon fermentor (a Brute trash can) increasing pounds of grain decreases water available. The amount of grain you use determines amount of potential alcohol...in pounds of alcohol, but not ABV of the wash as for that you have to know both weight of the grains and the weight of the water. Even then knowing the ABV of the post fermenting is only part of the story, what really matters is ABV and volume of the liquid that makes it into the stripping run. One saving grace is I believe it is hard to get to problematic ABV in all grain wash at typical/workable grain to water ratios.

I'm curious about which wheat you used for the calculator exercise. Most calculators I see have wheat PPG pretty high, whether flaked (unmalted) or malted. Low outliers are things like roasted wheat.

Re: Grain versus Potential Alcohol

Posted: Fri Jan 17, 2025 10:43 am

by Bolverk

My findings show 1 lb grain is approx equal .1 gals of proof (50% abv). Of course this is going to depend on your conversion and the grain as some has a high point per gallon (corn is higher, rye is lower) but it all averages out to about 1lb=.1gal.

Re: Grain versus Potential Alcohol

Posted: Fri Jan 17, 2025 10:46 am

by jonnys_spirit

2# of grain/gallon of water is highly recommended. Maybe a little more or less and should mash and convert to the 1.070-1.060 SG range which works well for a three strip run, one spirit run double distillation protocol. In your 15g fermenter I would use about 25lbs of grain and leave some headspace when you mash in the water so it doesn't overflow as it ferments...

Not sure how large your boiler is but if it's also 15g then you might consider a larger mash/ferment vessel in the 50g range so you just need to do a single mash/ferment cycle for each series of strip/spirit runs..

Cheers,

jonny

Re: Grain versus Potential Alcohol

Posted: Fri Jan 17, 2025 11:23 am

by Mr_Beer

Thanks for those who have replied so far.

Homebrewer11777 pointed out an obvious error -- thank you. The data for Wheat has been updated. I apologize for the error. In response to the 'type' of wheat, I picked an American Wheat. The notion was not to get any absolute metrics but instead a notion of the variability between different grain types. The original post has been updated.

In response to jonnys_spirit post I understand that have 'violated' the notion of 2# per gallon on purpose.

viewtopic.php?p=7799278#p7799278 is a thread regarding YLAY. Based on the YL folks specification data the 2# per gallon can be ignored in favor of their recommended water to grain to yeast ratios. I have stayed well within their guidelines at about 3.1 pounds per gallon.

In my setup the 15 gallon (aprox) of fermented mash is transferred and settled in two 7.5 gallon vessels for about a week. Then each 7 gallon is stripped separately since my boiler is 13 gallon size. The resulting 2.1 gallon (aprox) of the combined stripping run is then distilled again for the final product.

Since I am using YLAY, the notion of determining the OG based on traditional hydrometer measurement methods does not apply. YLAY takes the total initial product and converts it as it progresses and the yeast works on the starches in the grain methodically -- at least that is what I understand.

It seems clear that I am not getting the conversion that I should expect -- investigation will continue.

Re: Grain versus Potential Alcohol

Posted: Fri Jan 17, 2025 11:33 am

by jonnys_spirit

Copy that Mr_Beer! I don't think the YLAY is going to be appreciably different in conversion over a traditional mash approach. I do think that 3#/gallon will yield a higher ABV - probably about equivalent to a 1.090 mash and may also be a thicker porridge to work with... Which may be a bit higher ABV than desired for the best yeast environment. YLAY is a bit like "step feeding" the sugars to the yeast like you described so at least they are not presented with the higher osmotic pressure they would see in a fully converted 1.090 mash/slurry.. Sorry, I missed the YLAY note

Cheers,

j

Re: Grain versus Potential Alcohol

Posted: Fri Jan 17, 2025 11:55 am

by Mr_Beer

It would be nice if there were a separate forum area just for YLAY so users could trade hints/tips.

The product is getting lots of good reviews (and market share) in the EU. My experience so far is using a 400 mesh bag and no squeezing. My experience has been very positive so far -- nothing gooey or thick with any of the grains.

Re: Grain versus Potential Alcohol

Posted: Sat Jan 18, 2025 7:51 am

by Homebrewer11777

LOL you really should have mentioned YLAY in title or OP...

Reason for the calculations much easier to understand now. SG at time of pitching the YLAY is meaningless so you are calculating a theoretical SG as if full conversion had been obtained. You should be able to check the math based on resulting low wine quantity and ABV on a couple batches.

I'm curious...How much liquid wash do you get into the boiler from a 15 gallon ferment with 45# of mostly corn using a 400 mesh bag without squeezing?

Re: Grain versus Potential Alcohol

Posted: Sat Jan 18, 2025 9:26 am

by Mr_Beer

A recent recipe had ...

14 gallon Promise Land, AR (well)

27 pounds yellow 'clean corn' feed grade

8.4 pound rye grain -- unmalted

5.8 pounds barley (6 row)

4 pound Simpson Smoked Peated Malt

45 pounds total of grain.

Had 13 gallon of wash after bag drain.

After settling I had 12.5 gallon of wash -- .5 gallon loss to 'custard' -- yeast and trub in bottom of settling vessels.

viewtopic.php?p=7789607#p7789607 is a post showing some more detail of my method. Note that there is some 'squeezing' of the grain in the bag to get it to drain fully using belts and twisting them to tighten around the bag. When dumped it essentially dry. Currently I have switched to 400 micron bag -- the 800 micron is too fine and not needed.

Hope that answers your question.

Re: Grain versus Potential Alcohol

Posted: Sun Jan 19, 2025 12:51 am

by SW_Shiner

Mr_Beer wrote: ↑Fri Jan 17, 2025 11:55 am

It would be nice if there were a separate forum area just for YLAY so users could trade hints/tips.

There is an entire thread with lots of info and tips for YLAY

viewtopic.php?t=76531

Re: Grain versus Potential Alcohol

Posted: Sun Jan 19, 2025 2:36 am

by Saltbush Bill

SW_Shiner wrote: ↑Sun Jan 19, 2025 12:51 am

Mr_Beer wrote: ↑Fri Jan 17, 2025 11:55 am

It would be nice if there were a separate forum area just for YLAY so users could trade hints/tips.

There is an entire thread with lots of info and tips for YLAY

viewtopic.php?t=76531

Good work pointing that one out SW_Shiner, anyone who thinks they want to use Yellow Label needs to read that from end to end before they start asking questions, it probably the most comprehensive thread here on the subject.

Re: Grain versus Potential Alcohol

Posted: Sun Jan 19, 2025 6:35 am

by Mr_Beer

Thank you SW_Shiner and Saltbush Bill for your reference to the thread.

I respectfully disagree -- 907 posts spanning five years and not having YLAY in the post name is far from a separate area.

It is better than nothing, but so full of conjecture and speculation that is not very useful. In fact some of the later posts contradict the earlier posts. for the non-expert user it is almost too confusing.

Using the HomeDistiller search method I found over 100 threads with some mention of YLAY. The article you mentioned did not seem to be in the search list. And the list spans the timeframe when YLAY was not readily available (2018) to the present when it is readily available in America and becoming a major factor in EU distilling.

YLAY is not just a different brand it is a significant change in the traditional mash/ferment approach. In some sense it is 'new technology' and needs to have some explanation and assistance for the home distiller.

My suggestion was to have a separate area so folks that have actual experience can contribute and share in an area focused on this aspect or method of mashing and fermenting.

My prior comment regarding the need for a separate forum area devoted to YLAY still stands. I hope the forum administers thoughtfully consider it.

Re: Grain versus Potential Alcohol

Posted: Sat Mar 15, 2025 11:02 pm

by Garouda

Mr_Beer wrote: ↑Fri Jan 17, 2025 8:35 am

I did a little research and some computations. Here is what I came up with. No absolute truth here but a notion of potential yields based on grain type and various water amounts. It might help you as you develop your recipes.

This is how I proceed, the method is adapted from John Palmer's book “ HOW TO BREW "

You can find that book here :

viewtopic.php?p=7803275#p7803275

What you need to find is the dry extract of the cereals you are using, this is available on each malting company website.

There's also a table in that book providing those values (table 9 page 118-119).

The method is explained in Chapter 12.

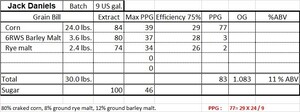

In fact, it's not rocket science. One has to know that one pound of sugar dissolved in one US Gal yields a Specific Gravity SG of 1.046, some sources say 1.045. I keep 1.046 like in that book. After that, 46 represents 100% yield, the value achieved by sugar. Let's take barley, the extract is 80, what is 46% of 80: 37, 37 PPG, Points Pound Gallon. The efficiency of your equipment is never 100%, you can mostly reach 75-80%. If we consider 75% efficiency, the maximum PPG yield by barley is going to be 37 X.75 = 28. The % ABV can be found in FermCalc.

- As an example, it's not a recipe I tried...