After spending a couple of weeks looking at this site I decided to have a go at building a still.

Unfortunately there is so much information and differing opinions about designs, it has taken me some time to decide what to build. Add the confusion about metric & imperial measurements and the problems finding supplies the right size, my brain has been slowly melting.

Due to the small size of my kitchen everything must be compact.

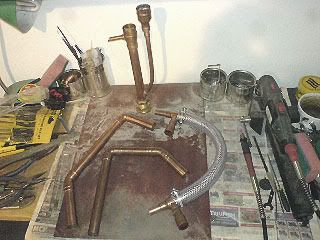

My pot is going to be similar to GingerBreadMan's v3 ( 11ltr pot with a bowl soldered/welded to the top ) with a 22mm compression tank connector.

I have made 2 small lyne arms 22mm dia. ( probably will not notice any difference between the 2 due to there small size ).

I have decided to make a curved liebig condenser, 15mm core and 18" 25m water jacket. Hopefully this will make the vapour/liquid make more contact with the copper surface and take up less space.

The most complicated part to build is my parrot, so I built it first. I am very happy with the result.

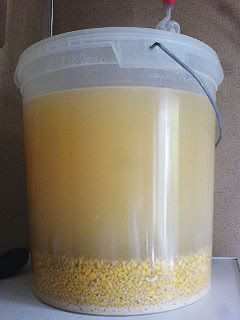

My first batch of UJSM is happily bubbling away after 4 days, I'm not sure how long it will take to finish, so I should hurry up and solder my pot together.