I've concluded that since this is my first build I'll keep it simple and replicate a known success story, namely the VM still.

Here's she is all in 2"

Boiler

50L stainless steel keg with a 6" triclover ferrule fitting and a 2400W stainless heating element

Reflux column = 42"

2" throughout packed with copper mesh and stainless scrubbers with a 2" to 1.5" concentric reducer at the top to act as a reflux centering device

Condenser = 13"

Double helix 1/4" stainless coils

Vapour management

2" to 1.5" T to a 1.5" stainless ball valve (I already had this - would have liked it to be a gate valve...)

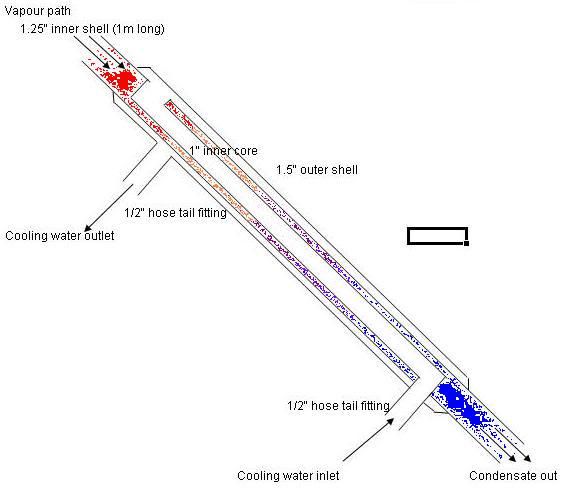

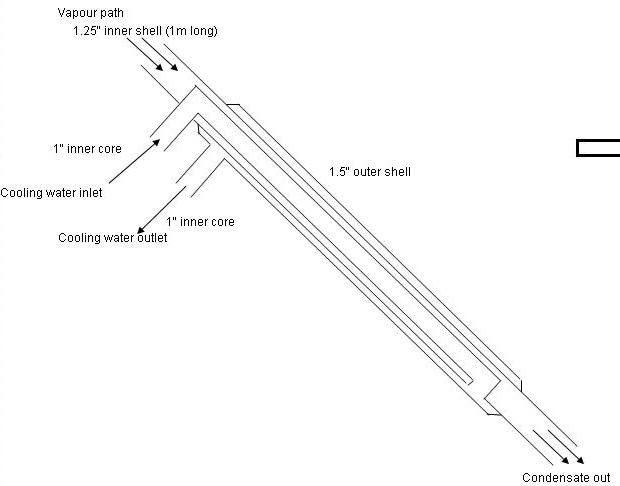

Leibig = 36"

Triple wall design with 2" outer...still sorting the sizes of the other tubes to insert...advice welcomed.

Still to do

- Wind the condenser coil

- Finish the drawing for the leibig and construct

- Build heating controller - currently just on/off control

- Buy more PTFE seals

- Listen to advice and make improvements

- Make and drink lots of grog - got the second part of that mastered

And the top of the keg looking inside to the stainless heating element

All those great parts and all the possibilities! Amazing collection man. Versatile as hell and built to last.

All those great parts and all the possibilities! Amazing collection man. Versatile as hell and built to last.