One reason behind this design stems from finding some scrap copper in a barrel at the back of a friends auto body shop... I told him how easy it would be to whip together into a still and he was somewhat skeptical... Now he's waiting for me to perfect this one so I can build one for him... I am currently looking for another 8-10 quart stock pot that will accept the stainless mixing bowl so I can use my 1500W element and controller... Test runs have all been done on an electric range with a metal plate for more consistent heat transfer...

When run in Pot Still/Stripper mode I fill the bottom of the column with marbles... It actually puts out almost the same high ABV in this mode as it does when using the stainless scrubber packed 18 inch reflux extension with a little tuning...

I've been very happy with the overall performance given the relatively small size... It provides me with more neutral spirit than I drink these days so it may end up being my primary still...

More Details:

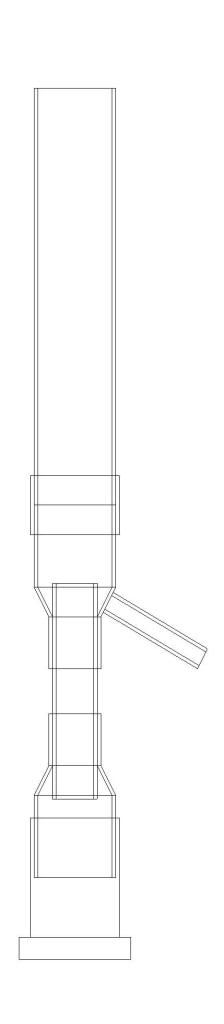

The column consists of 1.25 inch and .75 inch copper... The reflux extension measures 18 inches...

The condenser section measures approximately 9 inches...

I used 1.25 inch couplers to mate components, partly because the local Big Box stores only carry 1.25 X .75 reducers rather than couplers...

The stainless bowl measures approximately 9.5 inches and has a stainless steel sink drain attached... It might look like the rubber gasket is an issue but flour paste between the mating surfaces keeps any ethanol from causing leaching...

When running in reflux mode the upper reducer is calibrated to hold only one ounce of condensate before overflowing back into the column... I use a loose slant plate to deflect condensate from going directly back down the column which allows easy cleaning...

I will be replacing the needle valve and also plan on incorporating a small secondary condenser using either .5 or .75 inch copper because the final product comes off far too warm for my liking...

The primary condenser coil measures in the 7.5 inch range and was fashioned from just under 5 feet of .25 inch copper tubing... Approximately one quart of water per minute is more than enough to knock down all vapor and exits at 82F...