Crude but effective

Moderator: Site Moderator

Crude but effective

At last this column still actually works. The condenser is a thermos flask acting as an external water jacket and condenses all this thing can throw at it...I had my doubts but now I'm very happy that my time was not wasted.

The boiler was half a hot water cylinder; after some panel beating and patching I added a copper bottom, stainless pot for a rim and lid, and brass connector for the column. A wrought iron stand with a Roundabout BBQ ('H' shaped burner) does the heating.

All materials came from the recycling centre except for the column, thermometer, hoses and hose clamps. Column is a 50mm x 1m copper pipe.

My DWG which has waited for a month was put through last night. Total yield from 36Litres is 3.64 litres including heads and tails. The first 100ml went straight into the meths bottle; the next 500ml (at 86%), and the last 500ml designated as heads and tails because of operator inexperience. I am now sampling the remainder and relating the taste to the recorded data. The first 1.2L of the body measures 96% @21*C is smoother than the second 1.2L which measures 95%. The first half (diluted to 45%) is definately drinkable!

Can't wait to get the next batch of DWG going and do it again, and get the operator up to speed with some more experience.

Thank you all at Homedistiller and Homedistillation for sharing this mysterious craft/art/science.

All materials came from the recycling centre except for the column, thermometer, hoses and hose clamps. Column is a 50mm x 1m copper pipe.

My DWG which has waited for a month was put through last night. Total yield from 36Litres is 3.64 litres including heads and tails. The first 100ml went straight into the meths bottle; the next 500ml (at 86%), and the last 500ml designated as heads and tails because of operator inexperience. I am now sampling the remainder and relating the taste to the recorded data. The first 1.2L of the body measures 96% @21*C is smoother than the second 1.2L which measures 95%. The first half (diluted to 45%) is definately drinkable!

Can't wait to get the next batch of DWG going and do it again, and get the operator up to speed with some more experience.

Thank you all at Homedistiller and Homedistillation for sharing this mysterious craft/art/science.

cornflakes...stripped and refluxed

Re: Crude but effective

Hope the top of that is open to the atmosphere. It will be a bomb, if not.

Otherwise, looks like it should work.

Otherwise, looks like it should work.

It is the very things that we think we know, that keep us from learning what we should know.

Valved Reflux, 3"x54" Bok 'mini', 2 liebig based pots and the 'Blockhead' 60K btu propane heat

Valved Reflux, 3"x54" Bok 'mini', 2 liebig based pots and the 'Blockhead' 60K btu propane heat

-

manu de hanoi

- Trainee

- Posts: 798

- Joined: Mon Aug 13, 2007 9:06 am

Re: Crude but effective

if the inside of the thermos is glass that wont work

Re: Crude but effective

The thermos is all stainless and open at the top. It also contains a baffle that forces the vapors to the inner wall. I will post more pics soon.

cornflakes...stripped and refluxed

Re: Crude but effective

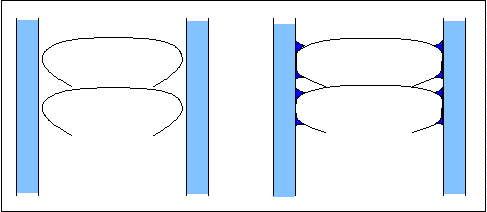

This is the inner and outer of the thermos with bits attached and ready to unite (all joining is by silver brazing) The cooling water is given a boost in a circular direction by the aiming of the inlet pipe at the bottom. Outlet pipe is attached at the top.

The reflux collar is a tight fit in the inner thermos shell, it forms a dam at the top and projects into the column at the bottom. The reflux hole is about 12mm above the bottom of the dam. Soldering the collar to the inner thermos shell without melting the reflux pipe join is tricky

All locked together:

Another tricky bit... the take-off must go through the water jacket. A big hole in the outer shell allows the oxy torch to get in and braze the pipe to the inner wall, right at the bottom of the dam on the other side. The pipe is flattened to allow the cooling water to flow around it better. The big hole is then closed by brazing a patch over it with the pipe just poking through; the patch looks like a washer (no pics, sorry). My tap came with a big adapter, so it was brazed over the patch and hides it.

The legs at the bottom of the baffle sit inside the reflux collar. Vapors are directed to the inner wall of the condenser, and condensates fall down the legs into the dam formed by the reflux collar. The alcohol comes out cool.

Yes a coil condenser may be less work, but I use what I have and all these bits were on hand at the time. If I could have got 12 feet of 6mm copper tubing easily then this would not have happened. Anyways I have since found a source of 6mm copper tubing, but now I'm drinking some vodka and the copper tubing can stay where it is.

Cheers to all!

All locked together:

Another tricky bit... the take-off must go through the water jacket. A big hole in the outer shell allows the oxy torch to get in and braze the pipe to the inner wall, right at the bottom of the dam on the other side. The pipe is flattened to allow the cooling water to flow around it better. The big hole is then closed by brazing a patch over it with the pipe just poking through; the patch looks like a washer (no pics, sorry). My tap came with a big adapter, so it was brazed over the patch and hides it.

The legs at the bottom of the baffle sit inside the reflux collar. Vapors are directed to the inner wall of the condenser, and condensates fall down the legs into the dam formed by the reflux collar. The alcohol comes out cool.

Yes a coil condenser may be less work, but I use what I have and all these bits were on hand at the time. If I could have got 12 feet of 6mm copper tubing easily then this would not have happened. Anyways I have since found a source of 6mm copper tubing, but now I'm drinking some vodka and the copper tubing can stay where it is.

Cheers to all!

Last edited by Ayay on Mon Dec 01, 2008 4:01 am, edited 1 time in total.

cornflakes...stripped and refluxed

Re: Crude but effective

Really like the baffles. Lateral thinking, literally!

P.S. Can you please downsize the pics to fit the page? Thanks.

P.S. Can you please downsize the pics to fit the page? Thanks.

Be safe.

Be discreet.

And have fun.

Be discreet.

And have fun.

Re: Crude but effective

Thanks, and downsized  and while I'm at it here is the stand and burner lit up:

Soon all will be covered in insulation; sheet metal and maybe rockwool over the stand/burner sides, and wool/sisalation for the upper bits.

and while I'm at it here is the stand and burner lit up:

Soon all will be covered in insulation; sheet metal and maybe rockwool over the stand/burner sides, and wool/sisalation for the upper bits.

Last edited by Ayay on Mon Dec 01, 2008 4:34 am, edited 1 time in total.

cornflakes...stripped and refluxed

-

manu de hanoi

- Trainee

- Posts: 798

- Joined: Mon Aug 13, 2007 9:06 am

Re: Crude but effective

congrats for the baffles. Perhaps just filling the condenser with an inner cylinder would have done (more or less) the same i believe.

Re: Crude but effective

I'm a great fan on doing that, after all its not all about the easiest way of doing stuff, Creativity is half the fun and challenge!Yes a coil condenser may be less work, but I use what I have and all these bits were on hand at the time.

Eitherway looks awesome to me!

Been Stilling since October 2007

I operate a 20ltr, 2m LM Reflux Still, based on the Bokmini Photos http://s391.photobucket.com/albums/oo358/ZAXBYC/

I use the head part of this unit for stripping and as a Pot Still- produces LOTS of flavour

I operate a 20ltr, 2m LM Reflux Still, based on the Bokmini Photos http://s391.photobucket.com/albums/oo358/ZAXBYC/

I use the head part of this unit for stripping and as a Pot Still- produces LOTS of flavour

Re: Crude but effective

Very nice work.

It is the very things that we think we know, that keep us from learning what we should know.

Valved Reflux, 3"x54" Bok 'mini', 2 liebig based pots and the 'Blockhead' 60K btu propane heat

Valved Reflux, 3"x54" Bok 'mini', 2 liebig based pots and the 'Blockhead' 60K btu propane heat

Re: Crude but effective

Great work, Ayay... Nice to see that thinking outside the box works sometimes... That's what moves the craft forward...

-

punkin

- Master of Distillation

- Posts: 2711

- Joined: Fri Oct 05, 2007 12:36 pm

- Location: Northern NSW Oz Trail Ya

Re: Crude but effective

Very pretty and also effective.

Re: Crude but effective

Manu, if only I knew! Yes an inner cylinder and maybe something to cause a spiral flow of vapor. The baffles came from a completely different idea that morphed as I tried to put it into metal and it ended up like it is.

Someone else may make a MkII, I'm nakkered with the metalwork. Space is limited and I must clean up the debris and then work on the brewing and refining arts.

Someone else may make a MkII, I'm nakkered with the metalwork. Space is limited and I must clean up the debris and then work on the brewing and refining arts.

cornflakes...stripped and refluxed

-

blanikdog

- Angel's Share

- Posts: 4545

- Joined: Tue Aug 09, 2005 11:55 pm

- Location: Bullamakanka, Oztrailya

Re: Crude but effective

There's always something new. Absa - bloody - lutely bonza job, AY. Shows the aussie attitude of giving it a burl and you're home and hosed.

blanik

blanik

Simple potstiller. Slow, single run.

(50 litre, propane heated pot still. Coil in bucket condenser - No thermometer, No carbon)

The Reading Lounge AND the Rules We Live By should be compulsory reading

Cumudgeon and loving it.

(50 litre, propane heated pot still. Coil in bucket condenser - No thermometer, No carbon)

The Reading Lounge AND the Rules We Live By should be compulsory reading

Cumudgeon and loving it.

Re: Crude but effective

that boiler is stunning, gives me some ideas

Whiskey, the most popular of the cold cures that don't work (Leonard Rossiter)

Re: Crude but effective

I appreciate the encouraging comments and am only too pleased to add something to this incredible resourse!

My first run through this still has a slight metallic taste that becomes stronger towards the end of the run. As many have advised before it must be traces of flux and metal residues. I did two water runs and a vinegar run followed by a good rinse, even so alcohol is another thing.

I may try tinning the inside of the brass tap and the brazed join at the bottom of the collector collar in case that is the cause of the contamination; or give them the brass treatment. Then I will dilute the first batch to 20%, re-run it and see what happens.

What I learned on the first alcohol run is:

- When the steam first hits the condenser and the thermometer races to the 80* there is a flood of condensates. Next time I will turn the heat down when the thermometer starts climbing and try to get a more gentle equilibrium.

- The condenser can handle the boiler at full blast and it settled at a very steady 77.8* after adjusting the reflux. The take-off was 0.9 Litres per hour at 95% purity. I will see what happens with less heat.

- The tap I use has a good feature in having the spindle seal above the level of the reflux dam; the seal is graphite, but it does not need to be very tight as it should only be sealing against a little vapor and not liquid. It's downside is all the flow adjustment happens within 1/8 of a turn. Have a plan to make a needle valve within the tap and will post pics of how that turns out.

-Will be following Husker's excellent tutorial http://homedistiller.org/forum/viewtopi ... 3#p6726973 much more closely.

My first run through this still has a slight metallic taste that becomes stronger towards the end of the run. As many have advised before it must be traces of flux and metal residues. I did two water runs and a vinegar run followed by a good rinse, even so alcohol is another thing.

I may try tinning the inside of the brass tap and the brazed join at the bottom of the collector collar in case that is the cause of the contamination; or give them the brass treatment. Then I will dilute the first batch to 20%, re-run it and see what happens.

What I learned on the first alcohol run is:

- When the steam first hits the condenser and the thermometer races to the 80* there is a flood of condensates. Next time I will turn the heat down when the thermometer starts climbing and try to get a more gentle equilibrium.

- The condenser can handle the boiler at full blast and it settled at a very steady 77.8* after adjusting the reflux. The take-off was 0.9 Litres per hour at 95% purity. I will see what happens with less heat.

- The tap I use has a good feature in having the spindle seal above the level of the reflux dam; the seal is graphite, but it does not need to be very tight as it should only be sealing against a little vapor and not liquid. It's downside is all the flow adjustment happens within 1/8 of a turn. Have a plan to make a needle valve within the tap and will post pics of how that turns out.

-Will be following Husker's excellent tutorial http://homedistiller.org/forum/viewtopi ... 3#p6726973 much more closely.

cornflakes...stripped and refluxed

Re: Crude but effective

Well Done, i love the pot and lid for the openin with the cross brace...

Nice idea on the baffle, if you are not doing it already, if you expand the side flaps of the baffle plates to touch the wall of the condensor

condensation will trap between the baffle and the condensor wall further cooling the baffles then your baffles become a working part of the condensor as well giving it more surface area..

Also you should do at least 1 if not 2 or 3 spirit runs you can reuse the same spirit then dump it before doing a proper run.

Hot ethanol vapor is very corossive and a good cleaner.

very nice work ...

look forward to hearing how you final product comes out..

cheers..

Nice idea on the baffle, if you are not doing it already, if you expand the side flaps of the baffle plates to touch the wall of the condensor

condensation will trap between the baffle and the condensor wall further cooling the baffles then your baffles become a working part of the condensor as well giving it more surface area..

Also you should do at least 1 if not 2 or 3 spirit runs you can reuse the same spirit then dump it before doing a proper run.

Hot ethanol vapor is very corossive and a good cleaner.

very nice work ...

look forward to hearing how you final product comes out..

cheers..

Re: Crude but effective

Thanks Decoy, there are a few contact points between the baffle and the condenser wall, I will tweak it to get as many contact points as possible for the reason you give, and having to ram the baffle in tight should make a big difference. I am pleased to hear another confirmation that the first run will pick up dirt and nasties despite all appearing to be clean.

The tap within a tap is done, now I have a coarse and a fine adjustment in one. The original tap does all the adjusting in 1/8th of a turn, and there is also a half turn of backlash; ie the threads are very big and loose.

I did the mods on an identical tap in case there is a stuffup, and will insert just the modified spindle into the tap on the condenser.

Here is the original tap assembled and exploded, note the black graphite seal in it's compression flange (it looks at one with the flange) - the graghite can be crumbled and recompressed not as tight: I drilled a hole all the way through the spindle to fit a stainless bicycle spoke. The drilling was done freehand and eyeballed from both ends, starting with a 1mm drill and following with a 2mm drill - luckily ended up pretty central. I cut some flutes across the threads of the spoke to turn it into a thread cutter. Because the thread cutter is not the most efficient, the threads are tight and there is no backlash. The threaded part of the spoke is a bigger diameter than the spoke wire. Left pic is a close-up of the top right pic where you can just see one of the flutes in the thread to make it a cutter, top right is the spoke in the freshly drilled hole, bot right is using the spoke to cut some thread at the top of the brass spindle. Another piece of spoke with good threads was used for the final needle. The spindle threaded in and a handle attached. I had to take the handle off later in order to put the spindle in a chuck when making the needle point. It was spun in a dremmel type motor and held against a file, and fine corundum paper. The handle is silver soldered with jewellers hard silver solder, (I am a jeweller by trade and these fiddly bits are easy...the big stuff aint!) I drilled some holes in the side of the big spindle of the tap, it is already hollowed out so there is plenty of space for the alcohol to flow to the needle. A bronze cap with a small hole for the needle seat was brazed on, closing the hollowed out portion except for the needle seat. The spoke was sharpened into a needle setting the length carefully so that the thread travel matches the open/closed position of the needle. In the left pic the needle is fully seated, right pic the needle is full open. You can see a faint line around the bevelled end - that is the seating point of the main tap. Complete tap, the handles of the needle valve were bent up for better clearance:. The outlet hole of the needle valve is 1.8mm in diameter (a tad smaller than the 2.0mm needle). If I need more output than what the needle hole can give, I can then crack open the main tap and fine adjust with the needle. The needle valve needs 6 turns to go from closed to full open.

Next step after installing the modified spindle is to treat the brass and re-run the first run.

Edited 9/12/08 to improve the explanation.

The tap within a tap is done, now I have a coarse and a fine adjustment in one. The original tap does all the adjusting in 1/8th of a turn, and there is also a half turn of backlash; ie the threads are very big and loose.

I did the mods on an identical tap in case there is a stuffup, and will insert just the modified spindle into the tap on the condenser.

Here is the original tap assembled and exploded, note the black graphite seal in it's compression flange (it looks at one with the flange) - the graghite can be crumbled and recompressed not as tight: I drilled a hole all the way through the spindle to fit a stainless bicycle spoke. The drilling was done freehand and eyeballed from both ends, starting with a 1mm drill and following with a 2mm drill - luckily ended up pretty central. I cut some flutes across the threads of the spoke to turn it into a thread cutter. Because the thread cutter is not the most efficient, the threads are tight and there is no backlash. The threaded part of the spoke is a bigger diameter than the spoke wire. Left pic is a close-up of the top right pic where you can just see one of the flutes in the thread to make it a cutter, top right is the spoke in the freshly drilled hole, bot right is using the spoke to cut some thread at the top of the brass spindle. Another piece of spoke with good threads was used for the final needle. The spindle threaded in and a handle attached. I had to take the handle off later in order to put the spindle in a chuck when making the needle point. It was spun in a dremmel type motor and held against a file, and fine corundum paper. The handle is silver soldered with jewellers hard silver solder, (I am a jeweller by trade and these fiddly bits are easy...the big stuff aint!) I drilled some holes in the side of the big spindle of the tap, it is already hollowed out so there is plenty of space for the alcohol to flow to the needle. A bronze cap with a small hole for the needle seat was brazed on, closing the hollowed out portion except for the needle seat. The spoke was sharpened into a needle setting the length carefully so that the thread travel matches the open/closed position of the needle. In the left pic the needle is fully seated, right pic the needle is full open. You can see a faint line around the bevelled end - that is the seating point of the main tap. Complete tap, the handles of the needle valve were bent up for better clearance:. The outlet hole of the needle valve is 1.8mm in diameter (a tad smaller than the 2.0mm needle). If I need more output than what the needle hole can give, I can then crack open the main tap and fine adjust with the needle. The needle valve needs 6 turns to go from closed to full open.

Next step after installing the modified spindle is to treat the brass and re-run the first run.

Edited 9/12/08 to improve the explanation.

cornflakes...stripped and refluxed

Re: Crude but effective

the most important thing i forgot to mention....

you have a full copper boiler, whydo you want to run a column.?

consider running it as a pot still.....

you have a full copper boiler, whydo you want to run a column.?

consider running it as a pot still.....

Re: Crude but effective

Decoy, As soon as I find a short piece of 2" pipe I will do pot stilling. Young fruit are on the trees and I hope to have it ready when they're ripe and dropping off.

Of the many options for brewing I chose Tater's DWWG as the most foolproof for me, sugar wash is quick and easy, and thus vodka must be the product; also more foolproof for a beginner I thought.

Will practise pot stillin with the DWWG because they say it has a good flavour!

Of the many options for brewing I chose Tater's DWWG as the most foolproof for me, sugar wash is quick and easy, and thus vodka must be the product; also more foolproof for a beginner I thought.

Will practise pot stillin with the DWWG because they say it has a good flavour!

cornflakes...stripped and refluxed

Re: Crude but effective

The DWWG or UJSM are both great recipes for a beginning potstiller. Quite a few keep ferments of UJSM going all year.

It is the very things that we think we know, that keep us from learning what we should know.

Valved Reflux, 3"x54" Bok 'mini', 2 liebig based pots and the 'Blockhead' 60K btu propane heat

Valved Reflux, 3"x54" Bok 'mini', 2 liebig based pots and the 'Blockhead' 60K btu propane heat

Re: Crude but effective

Further developments:

1. Added a control valve to the gas line. Lack of proper heat control meant that the reflux runs had to go at full capacity. Fortunately the reflux produced 95% and the condenser coped. Pot stillin was not possible without being able to control the heat and reflux stillin will benefit too. I now have fine heat control.

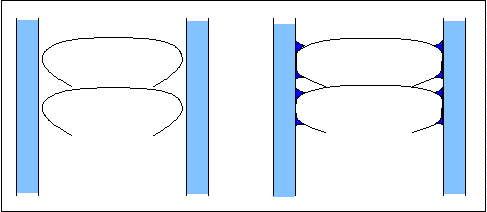

2. Made a coil to replace the baffles. The jacket alone used too much water (about 4 litres/minute) when the boiler was going flat-out. Despite this the exit pipe was cold therefore the condenser was not very efficient at full capacity. The bottom baffle remains as a deflector for the condensates. The double coil has a piece of tube rammed 1/3 the way from the top to close off the vapor flow up the middle. The top of the tube was split and folded out and soldered to lock the two coils together (a bit of scalloping gives it the techno look), and the bottom of the tube is capped. Water flows down the outer coil and up the inner coil. 3. Made some some copper 'Y's to split the inlet and combine the outlets so as to run the the jacket and the coil together. I thought the outlet 'Y' may cause some back pressure problems for one of the circits so I cut a slit and soldered a vertical web as shown in the diagram on the right. This means if one of the outlets is putting out more water then it will help the other outlet by venturi action rather than try and run up the other outlet. Here the condenser is hosed up and the ratio of flow between the coil and the jacket measures approx 2.5:1 in favor of the jacket. I was surprised because the short inlet jet (2") to the jacket is a smaller diameter tube than the tubing in the coil (15'); so length of pipe has a big effect on the flow. Here are pics of the still in pot mode and reflux mode. The new gas knob is the white round knob on the BBQ burner. The new coil/jacket condenser is far more efficient needing a maximum of 1l/minute at full heat, and around 0.5l/minute at low pot-still heat. While running the still I can compare the outlet temps of each cooling water outlet. Before running the still I added a tap to the jacket cooling water inlet thinking that an equal flow through the jacket and coil would be best, but the jacket actually absorbs much more heat than the coil and the tap remains fully open! I believe the reason is the jacket catches the hottest vapors direct from the deflector. The jacket also cools the collection collar and product outlet. I will move the tap to the coil inlet so I can adjust to get both cooling water outlets to the same temperature and hopefully improve efficiency a little more.

1. Added a control valve to the gas line. Lack of proper heat control meant that the reflux runs had to go at full capacity. Fortunately the reflux produced 95% and the condenser coped. Pot stillin was not possible without being able to control the heat and reflux stillin will benefit too. I now have fine heat control.

2. Made a coil to replace the baffles. The jacket alone used too much water (about 4 litres/minute) when the boiler was going flat-out. Despite this the exit pipe was cold therefore the condenser was not very efficient at full capacity. The bottom baffle remains as a deflector for the condensates. The double coil has a piece of tube rammed 1/3 the way from the top to close off the vapor flow up the middle. The top of the tube was split and folded out and soldered to lock the two coils together (a bit of scalloping gives it the techno look), and the bottom of the tube is capped. Water flows down the outer coil and up the inner coil. 3. Made some some copper 'Y's to split the inlet and combine the outlets so as to run the the jacket and the coil together. I thought the outlet 'Y' may cause some back pressure problems for one of the circits so I cut a slit and soldered a vertical web as shown in the diagram on the right. This means if one of the outlets is putting out more water then it will help the other outlet by venturi action rather than try and run up the other outlet. Here the condenser is hosed up and the ratio of flow between the coil and the jacket measures approx 2.5:1 in favor of the jacket. I was surprised because the short inlet jet (2") to the jacket is a smaller diameter tube than the tubing in the coil (15'); so length of pipe has a big effect on the flow. Here are pics of the still in pot mode and reflux mode. The new gas knob is the white round knob on the BBQ burner. The new coil/jacket condenser is far more efficient needing a maximum of 1l/minute at full heat, and around 0.5l/minute at low pot-still heat. While running the still I can compare the outlet temps of each cooling water outlet. Before running the still I added a tap to the jacket cooling water inlet thinking that an equal flow through the jacket and coil would be best, but the jacket actually absorbs much more heat than the coil and the tap remains fully open! I believe the reason is the jacket catches the hottest vapors direct from the deflector. The jacket also cools the collection collar and product outlet. I will move the tap to the coil inlet so I can adjust to get both cooling water outlets to the same temperature and hopefully improve efficiency a little more.

cornflakes...stripped and refluxed

Re: Crude but effective

Further developments: added an aluminium skirt to deflect the waste heat up the sides of the boiler, and a 'tea cosy' type insulation on the top half of the boiler and short column.Makes the gas go further.

My new and expensive parrot at the end of a pot still rum spirit run.

My new and expensive parrot at the end of a pot still rum spirit run.

cornflakes...stripped and refluxed

-

Mud

- Swill Maker

- Posts: 192

- Joined: Fri Sep 19, 2008 5:10 pm

- Location: The uncivilized part of PA, USA

Re: Crude but effective

Very nice rig, Ayay. Excellent craftmanship. Would you mind showing us a close up of the fill port? Looks like bail over a cap?

Re: Crude but effective

Here you go Mud  The rim and lid are a stainless saucepan. The saucepan was cut so that the rim sat nicely on the boiler, I brazed it on, then cut the hole 10mm smaller and hammered the 10mm of copper up inside the rim and brazed some more - a daggy lot more! The rim had warped and was straightened by placing strips of wood under and over the rim 90* to each other and squeezing in the centre with a 'G'clamp.

The rim and lid are a stainless saucepan. The saucepan was cut so that the rim sat nicely on the boiler, I brazed it on, then cut the hole 10mm smaller and hammered the 10mm of copper up inside the rim and brazed some more - a daggy lot more! The rim had warped and was straightened by placing strips of wood under and over the rim 90* to each other and squeezing in the centre with a 'G'clamp.

There is an aquarium grade silicon seal on the lid. Condensation in the lid will bybass the seal so there is very little contact, and the lid is not the original for the saucepan - it is a tight fit.

The loops for the cross bar are copper pipe, and the cross bar and pressure pad are iron. The iron was waxed with silicon car polish and has a funky patina.

There is an aquarium grade silicon seal on the lid. Condensation in the lid will bybass the seal so there is very little contact, and the lid is not the original for the saucepan - it is a tight fit.

The loops for the cross bar are copper pipe, and the cross bar and pressure pad are iron. The iron was waxed with silicon car polish and has a funky patina.

cornflakes...stripped and refluxed

-

Mud

- Swill Maker

- Posts: 192

- Joined: Fri Sep 19, 2008 5:10 pm

- Location: The uncivilized part of PA, USA

Re: Crude but effective

That's pretty slick, sir. Nice job.

Re: Crude but effective

Looks good. At first glance/before reading on, I thought that thermos at the top was an exhaust tip (yes, I think I truly think in diesel and alcohol...)

dunno what to put here, on all the other forums im on there is a description of my truck here. heh

Re: Crude but effective

Exhaust tip's not a bad idea! Would be heavier and stronger. My next expriment is a flying saucer shape condenser with a spiral coil inside, low and wide so I can use a longer column. I have a shallow stainless bowl and with the lid upside down looks promising

cornflakes...stripped and refluxed