So I started out by reading pretty much everything I could find on the topic, starting with these forums and the wiki. I learnt a lot from this and really suggest reading through the static menu at least once.

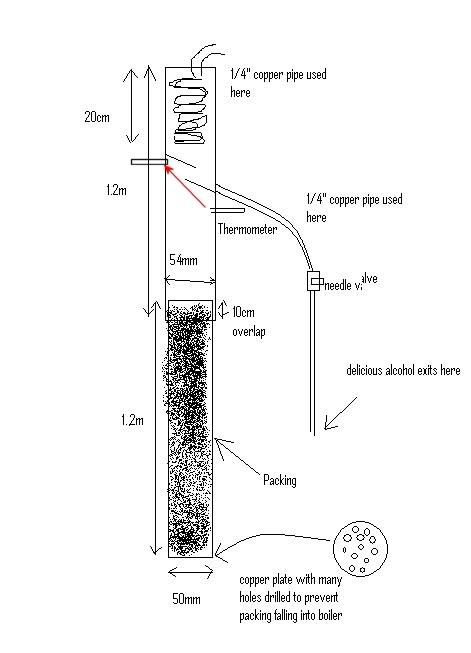

Initially I had planned on purchasing a commercial 5L still, however the members of this forum quickly informed me that this was a bad idea and that I would be far better off building my own (it looks like it will end up being cheaper & much higher capacity). So I went back to the wiki and read some more and eventually came across the mini-still plans. I chose these as it is a simple design that I should be able to construct, in addition to this it would be possible to add additional pipe later to increase the length of the still if desired.

For the boiler I have decided to add a heating element to a keg to create a 50L boiler as shown here. So I asked around and pretty quickly I had three kegs, two were of the sanke type and one of the german flat top type. I plan to use the other two kegs as containers for fermenting.

I then went out to a local scrap metal place and asked about copper pipe and ended up with the 24" of 2" copper pipe that I needed for the mini still, for an excellent price of $5 AUD! I had to go to a plumbing store in order to get the 1/4" copper pipe for the condenser coil, this set me back around $55. So I'm not doing too badly at the moment. My goal is to keep the cost below $300 AUD, but we shall see how things go!

Below you can see what I've got so far (click for larger image). Hopefully I'll be able to get the coil wound sometime this weekend! I am currently searching for local sources (within Australia) for appropriate heating elements / dimmers for this project.

I should update again within the next few days!