Thoughts on my reflux column design.

Moderator: Site Moderator

-

billy_bob_95

- Novice

- Posts: 79

- Joined: Sun Jun 29, 2008 6:31 pm

Re: Thoughts on my reflux column design.

Is this your reflux column? If so I would just build a VM head that could be attached to the column in place of the reflux head. You could remove the second condenser above the take off from the vapor line, and reduce down from there for a VM. Just looking at the photo I think the first option would be the simplest. How tall is your column right where the reflux head can be removed from the column?

2" Copper Reflux Rig

15.5 Gallon Boiler

3" Copper VM Rig

15.5 Gallon Boiler

3" Copper VM Rig

-

chunkystyles

- Novice

- Posts: 55

- Joined: Mon Aug 04, 2008 7:36 am

- Location: Arkansas

Re: Thoughts on my reflux column design.

I'm not sure how tall the column is. I didn't build it so I never have measured it. If it were at my house I could measure it for you, but I don't know. If I had to guess I would say somewhere between 36" and 42".

I've attached another diagram that shows how I interpreted your post, billy bob.

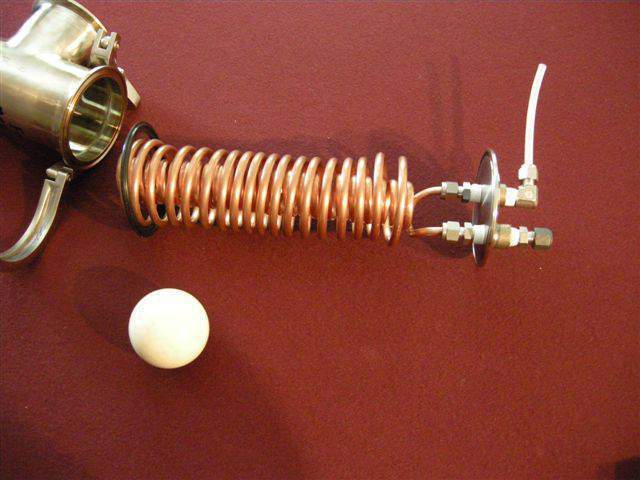

Let me know if this is what you meant. This design will be very hard for me to adapt because of the way that my condensers are made. They are attached to 3" ferruled end caps. Here is a a close up pic of one of my condensers.

I've attached another diagram that shows how I interpreted your post, billy bob.

Let me know if this is what you meant. This design will be very hard for me to adapt because of the way that my condensers are made. They are attached to 3" ferruled end caps. Here is a a close up pic of one of my condensers.

-

chunkystyles

- Novice

- Posts: 55

- Joined: Mon Aug 04, 2008 7:36 am

- Location: Arkansas

Re: Thoughts on my reflux column design.

Since my last post didn't get any response, let me ask my question in a different manner. Is it absolutely necessary to have the valve after the turn down? What are the repercusions of having the valve before the turn down?

-

DestructoMutt

- Swill Maker

- Posts: 321

- Joined: Thu Jun 14, 2007 4:41 pm

- Location: Not that Vancouver, the original one.

Re: Thoughts on my reflux column design.

too much garbage to wade through to get to your question, thanks for restating.

the other concern i have with a smaller valve (people typically suggest a 3/4" or 1/2" ball valve) after the elbow has to do with fluid dynamics and the flow of fluids in pipes (gas and vapor behave like liquid fluids when flowing in pipes). which is that, for a consistent pressure system, the total flow is controlled by the smallest pipe diameter that the flow faces. which means that if the vapor has not condensed before reaching the ball valve, the small diameter of the ball valve will restrict the flow of vapor entering the product condensor, limiting the maximum amount of product takeoff. I use a 1" gate valve.

personally, i like having the valve above the elbow. nothing accumulates against the valve during equilibrium, it all drains back to the column. however, some people say that you can get away with a smaller valve by putting it after the elbow, but then you have stuff accumulating on top of the valve, stuff that might belong in your hearts collection.chunkystyles wrote:Since my last post didn't get any response, let me ask my question in a different manner. Is it absolutely necessary to have the valve after the turn down? What are the repercusions of having the valve before the turn down?

the other concern i have with a smaller valve (people typically suggest a 3/4" or 1/2" ball valve) after the elbow has to do with fluid dynamics and the flow of fluids in pipes (gas and vapor behave like liquid fluids when flowing in pipes). which is that, for a consistent pressure system, the total flow is controlled by the smallest pipe diameter that the flow faces. which means that if the vapor has not condensed before reaching the ball valve, the small diameter of the ball valve will restrict the flow of vapor entering the product condensor, limiting the maximum amount of product takeoff. I use a 1" gate valve.

Re: Thoughts on my reflux column design.

I have the (gate) valve before the elbow. That is the original design for VM, and I have not seen anything that says putting the valve after is better. At most it is a little more convenient to reach, that is all.

The amount of initial condensate that pools above a valve after the elbow seems pretty small, a few tens of ml. I don't see that being a problem.

My valve is 3/4" gate. It is only open a max of about 3.5-4 turns (out of 11 for fully open) during the hearts cut. And others have used 1/2" ball valves (after the elbow) on 3" VM columns with no apparent problems. So there does not seem to be any advantage to using a larger valve. And some disadvantages, they cost much more, weigh more, etc.

The more critical design feature seems to be the ratio of the cross-sectional-areas of the column and the take-off port itself, which strongly influences vapour flow into the take-off port. If that is good, then the valve size is not so critical (within reason, of course).

The amount of initial condensate that pools above a valve after the elbow seems pretty small, a few tens of ml. I don't see that being a problem.

My valve is 3/4" gate. It is only open a max of about 3.5-4 turns (out of 11 for fully open) during the hearts cut. And others have used 1/2" ball valves (after the elbow) on 3" VM columns with no apparent problems. So there does not seem to be any advantage to using a larger valve. And some disadvantages, they cost much more, weigh more, etc.

The more critical design feature seems to be the ratio of the cross-sectional-areas of the column and the take-off port itself, which strongly influences vapour flow into the take-off port. If that is good, then the valve size is not so critical (within reason, of course).

Be safe.

Be discreet.

And have fun.

Be discreet.

And have fun.

-

DestructoMutt

- Swill Maker

- Posts: 321

- Joined: Thu Jun 14, 2007 4:41 pm

- Location: Not that Vancouver, the original one.

Re: Thoughts on my reflux column design.

the smallest diameter pipe that the vapor encounters before condensing into liquid is the critical control point for the size issue on the product take-off.

Scenario A: for instance- you use a 1" valve, and follow it up with a liebig condensor that is 1" pipe inside 1 1/4" pipe, then reduce to 1/2" - the smallest diameter pipe that the vapor sees is 1" (assuming it is all condensed before leaving the product condensor).

Scenario B: alternatively - you use a 1" valve but immediately reduce to a 1/2" pipe inside a 3/4" pipe liebig - the smallest diameter pipe the vapor sees is 1/2" - it is still in vapor form when it tries to enter the 1/2" pipe and this causes a restriction in the flow.

many people on here use some form of scenario B, it's not bad, is less expensive and less cumbersome weight wise, but they don't understand the vapor flow through a restriction problem. there are a few who use scenario A. if you understand fluid dynamics, scenario A is the more efficient and will allow greater product take-off, assuming your column is sized appropriately (diameter, length, vapor production) and your operating procedures match (increased equilibiration time, slooooow foreshots removal, watching the head temperature to make sure you don't unbalance the reflux cycle).

Scenario A: for instance- you use a 1" valve, and follow it up with a liebig condensor that is 1" pipe inside 1 1/4" pipe, then reduce to 1/2" - the smallest diameter pipe that the vapor sees is 1" (assuming it is all condensed before leaving the product condensor).

Scenario B: alternatively - you use a 1" valve but immediately reduce to a 1/2" pipe inside a 3/4" pipe liebig - the smallest diameter pipe the vapor sees is 1/2" - it is still in vapor form when it tries to enter the 1/2" pipe and this causes a restriction in the flow.

many people on here use some form of scenario B, it's not bad, is less expensive and less cumbersome weight wise, but they don't understand the vapor flow through a restriction problem. there are a few who use scenario A. if you understand fluid dynamics, scenario A is the more efficient and will allow greater product take-off, assuming your column is sized appropriately (diameter, length, vapor production) and your operating procedures match (increased equilibiration time, slooooow foreshots removal, watching the head temperature to make sure you don't unbalance the reflux cycle).

Re: Thoughts on my reflux column design.

Understand what you are saying, DM. But the important point is that the valve is not fully open for normal take-off, so in our application it is the limiting restriction for vapour flow into the take-off arm, not the tube size. (Allowing for the column/take-off port ratio issue as well.)

Be safe.

Be discreet.

And have fun.

Be discreet.

And have fun.

-

DestructoMutt

- Swill Maker

- Posts: 321

- Joined: Thu Jun 14, 2007 4:41 pm

- Location: Not that Vancouver, the original one.

Re: Thoughts on my reflux column design.

don't be offended Hook, but my followup was directed to chunkystyles.HookLine wrote:Understand what you are saying, DM. But the important point is that the valve is not fully open for normal take-off, so in our application it is the limiting restriction for vapour flow into the take-off arm, not the tube size. (Allowing for the column/take-off port ratio issue as well.)

there are people on this forum (or is it the other forums) that go for maximum output - 6' tall x 3" diameter column to feed their habit - but whine about the lack of output, and don't consider the restriction facing the vapor and ......

anyways, the point is....., i'm sorry, what was the point again? oh yes, here is additional information for you to consider in designing your column....don't say we didn't tell you everything.

-

chunkystyles

- Novice

- Posts: 55

- Joined: Mon Aug 04, 2008 7:36 am

- Location: Arkansas

Re: Thoughts on my reflux column design.

Thanks a lot guys. I know a lot more about VM stills now and I think I can successfully design one now. I've been waiting until I felt that I completely understood how it worked before I tried to get the new parts made.

As soon as I get it all put together I will post some pics. It could be a week or two.

As soon as I get it all put together I will post some pics. It could be a week or two.

-

trial&error

- Novice

- Posts: 55

- Joined: Mon Apr 27, 2009 6:49 pm

- Location: earth

Re: Thoughts on my reflux column design.

dont you want the reflux condenser lower/before the product take off/condenser so that it knocks down the heavier vapor before it get collected

-

DestructoMutt

- Swill Maker

- Posts: 321

- Joined: Thu Jun 14, 2007 4:41 pm

- Location: Not that Vancouver, the original one.

Re: Thoughts on my reflux column design.

review the differences between Liquid Management, Cooling Mangement and Vapor Management heads.

the reflux condensor is in different positions based on operating pricipal.

the reflux condensor is in different positions based on operating pricipal.

-

DestructoMutt

- Swill Maker

- Posts: 321

- Joined: Thu Jun 14, 2007 4:41 pm

- Location: Not that Vancouver, the original one.

Re: Thoughts on my reflux column design.

upon re-reading your post, i think i missed the point of your question.trial&error wrote:dont you want the reflux condenser lower/before the product take off/condenser so that it knocks down the heavier vapor before it get collected

there is a still design being promoted on the net that has "cooling" tubes running through the bottom of the column. that still column design is based on a "lack of understanding" of the distillation process. you can't "knock out" the high boiling point substances, they have to fall out on their own. if you attempt to "knock out" the high boiling point substances you will also "knock out" the low boiling point substances. so no, you don't want a "condensor" at the bottom, or middle of a column. a reflux condensor goes on top of the column.

is this what you were asking about?

-

trial&error

- Novice

- Posts: 55

- Joined: Mon Apr 27, 2009 6:49 pm

- Location: earth

Re: Thoughts on my reflux column design.

which part of the parent site covers that? i understand the basic concept of them both.DestructoMutt wrote:review the differences between Liquid Management, Cooling Mangement and Vapor Management heads.

the reflux condensor is in different positions based on operating pricipal.

vapor with impurities will be heavier, so as it's cooled it hits the point were it can no longer travel up the column and fall back down, and the vapor that doesnt have impurities well cool but still be light enough to continue up the column. so would you want the reflux condenser below the product take offDestructoMutt wrote:upon re-reading your post, i think i missed the point of your question.trial&error wrote:dont you want the reflux condenser lower/before the product take off/condenser so that it knocks down the heavier vapor before it get collected

there is a still design being promoted on the net that has "cooling" tubes running through the bottom of the column. that still column design is based on a "lack of understanding" of the distillation process. you can't "knock out" the high boiling point substances, they have to fall out on their own. if you attempt to "knock out" the high boiling point substances you will also "knock out" the low boiling point substances. so no, you don't want a "condensor" at the bottom, or middle of a column. a reflux condensor goes on top of the column.

is this what you were asking about?

-

chunkystyles

- Novice

- Posts: 55

- Joined: Mon Aug 04, 2008 7:36 am

- Location: Arkansas

Re: Thoughts on my reflux column design.

What you are talking about here is the design behind a CM still, like my original design. In a VM still you need the reflux condenser to be higher than the product takeoff arm. Here is the post that describes the differences in the stills.trial&error wrote:which part of the parent site covers that? i understand the basic concept of them both.

vapor with impurities will be heavier, so as it's cooled it hits the point were it can no longer travel up the column and fall back down, and the vapor that doesnt have impurities well cool but still be light enough to continue up the column. so would you want the reflux condenser below the product take off

Re: Thoughts on my reflux column design.

trial&error, as I see it, the problem with your idea is that with most condensers the vapors would be condensed into reflux within the first few inches so no vapor would ever enter the take off branch... With VM columns the reflux coil needs to be approximately 1/2 to 1 column diameter above the take off branch, give or take, because that will place the highest purity level right at the branch opening... If you're open to experimentation it would be interesting to hear your results of varying the upper section height to raise and lower the reflux condenser with relation to the branch...

-

DestructoMutt

- Swill Maker

- Posts: 321

- Joined: Thu Jun 14, 2007 4:41 pm

- Location: Not that Vancouver, the original one.

Re: Thoughts on my reflux column design.

unfortunatly, no. that's a basic and beginning misconception about the process. and it's not about who or what is heavier (ethanol is heavier than water on a molecular level).trial&error wrote:vapor with impurities will be heavier, so as it's cooled it hits the point were it can no longer travel up the column and fall back down, and the vapor that doesnt have impurities well cool but still be light enough to continue up the column. so would you want the reflux condenser below the product take off

distillation is a thermal/heat driven process, so it's boiling point temperature that matters.

a condensor removes heat (it doesn't so much remove as takes, the difference being akin to the government removing some of your income for taxes vs. a mugger taking your wallet and valuables). it is a true "equal opportunity thief" in that respect, as it doesn't care who or what it is taking heat from.

the vapor (made up of the substances in the wash, and of varying proportions based on wash composition and subsequent boiling point temperature) travels up the column. some of the substances give up their heat more readily than others, and in giving up their heat, they phase change back to liquid. as the "impurities" phase change back to liquid form, the remainng vapor increases in ethanol composition. as the ethanol composition of the vapor increases, the boiling point temperature decreases thus keeping the vapor in the vapor phase. this continues up the column. (initially it's not ethanol that works it's way up the column though, it's the foreshots, which have a lower boiling point temperature than ethanol - don't forget this, as it's important when collecting the foreshots and limiting the amount of heads produced). the temperature gradient that develops in the column is what enables the process to occur (remember, it's a thermal/heat process), and the temperature gradient isn't something you can artificially impose onto a column. the temperature gradient is something that occurs based on four or five variables and one of them you can't control (wash composition and it's rate of change throughout a run). and the gradient is continuously changing throughout the run also.

a fractionating column (aka: stripping column; a packed column with out a reflux condensor) can produce a product that is 92%ABV, if run slowly enough. which means, if you run your reflux fitted column properly, you will be able to get 92% ABV product even if the reflux condensor is turned off. which implies that a reflux column actually has two stages. the lower part of the column acts like a fractionating column and then there is a short section on top in which the reflux cycle occurs. the reflux cycle is when you take 92% ABV in vapor form, condense it and dribble the liquid back over the packing from which it came. if dribbled slow enough, it will flash vaporize because of the temperature of the packing (check out the Cox diagram showing %ABV ethanol vs. boiling point temperature, and the calculator on Tony's site). upon vaporizing the liquid jumps from 92 to 93%ABV (?, sorry don't have the calculator at my disposal right now). and if you let the cycle continue long enough, you will end up with 95.6%ABV cycling in the reflux section of t he column. the tricky part is in removing product so that you don't upset the balance, take too much 95.5%ABV off too quickly, you won't leave enough for the cycle to be at it's "end" point, and the product ABV% will quickly drop back to 92%ABV.

-

DestructoMutt

- Swill Maker

- Posts: 321

- Joined: Thu Jun 14, 2007 4:41 pm

- Location: Not that Vancouver, the original one.

Re: Thoughts on my reflux column design.

the problem with writing extemporaneously is that you sometimes forget to include things, and i did forget to include....

a very important part of the process is that the vapor produced from a wash has a higher proportion of the lower boiling point temperature substances than of the higher boiling point substances....and knowing that boiling point temperature is the same as condensation point temperature....and looking at the Cox phase diagram of %ABV vs. temperature for water vs. ethanol.... you see that a 10%ABV liquid, boiling at 93C, produces a vapor at 55%ABV, which has a boiling point/condensation point temperature of about 82.5C, which means, the vapor won't fully condense until enough heat energy has been removed from it to lower its temperature to 82.5C.....however, while it's traveling up the column and cooling down, water molecules and ethanol are condensing out, while other ethanol molecules are becoming vaporized (it takes less heat energy to vaporize an ethanol molecule, especially when it is in a liquid that is high in ABV; see the Cox phase diagram) due to the heat energy being given up by the molecules condensing. the simplified net affect is that water condenses out as the vapor rises and gets richer in ethanol, but the water has to be there in vapor form because that is how the heat is transferred/transported up the column (the ethanol mostly holds onto it's heat energy because it stays in vapor form, the water is the main transporter of heat in the column due to its action of rising up the column as a vapor and then condensing, releasing it's heat to the surroundings, the surroundings being the the packing and the ethanol rich vapor). the condensed water runs down the column and back into the boiler. (check out the %ABV for a vapor from a 1%ABV wash - 8.7%ABV, which has a boiling point temperature of 93.5C - which indicates that as you progress through the run, the water running down the column will be virtually depleted of alcohol.)

so, if the vapor starts up the column at 55%ABV, it will have started the climb with a boiling/condensation point temperature of 82.5C, but by the time it reaches the point in the column where the temperature is 82.5C, the composition of the vapor will have changed to 70, or 75 or 80%ABV, with a subsequent decrease in it's boiling/condensation point temperature, thus remaining in vapor form throughout it's trip up the column.

a very important part of the process is that the vapor produced from a wash has a higher proportion of the lower boiling point temperature substances than of the higher boiling point substances....and knowing that boiling point temperature is the same as condensation point temperature....and looking at the Cox phase diagram of %ABV vs. temperature for water vs. ethanol.... you see that a 10%ABV liquid, boiling at 93C, produces a vapor at 55%ABV, which has a boiling point/condensation point temperature of about 82.5C, which means, the vapor won't fully condense until enough heat energy has been removed from it to lower its temperature to 82.5C.....however, while it's traveling up the column and cooling down, water molecules and ethanol are condensing out, while other ethanol molecules are becoming vaporized (it takes less heat energy to vaporize an ethanol molecule, especially when it is in a liquid that is high in ABV; see the Cox phase diagram) due to the heat energy being given up by the molecules condensing. the simplified net affect is that water condenses out as the vapor rises and gets richer in ethanol, but the water has to be there in vapor form because that is how the heat is transferred/transported up the column (the ethanol mostly holds onto it's heat energy because it stays in vapor form, the water is the main transporter of heat in the column due to its action of rising up the column as a vapor and then condensing, releasing it's heat to the surroundings, the surroundings being the the packing and the ethanol rich vapor). the condensed water runs down the column and back into the boiler. (check out the %ABV for a vapor from a 1%ABV wash - 8.7%ABV, which has a boiling point temperature of 93.5C - which indicates that as you progress through the run, the water running down the column will be virtually depleted of alcohol.)

so, if the vapor starts up the column at 55%ABV, it will have started the climb with a boiling/condensation point temperature of 82.5C, but by the time it reaches the point in the column where the temperature is 82.5C, the composition of the vapor will have changed to 70, or 75 or 80%ABV, with a subsequent decrease in it's boiling/condensation point temperature, thus remaining in vapor form throughout it's trip up the column.

Re: Thoughts on my reflux column design.

Interesting comments, DM. Got some questions/comments:

What would you say these variables are?DestructoMutt wrote:the temperature gradient is something that occurs based on four or five variables

Are you saying that there is a 92% limit for a packed no-reflux column? AFAIK, in theory, a packed no-reflux column that is tall enough, and run slow enough, should deliver 95.6%, or very close. The point of returning reflux to the packed column is that it dramatically reduces the length of the column needed for a given column diameter, output rate, and purity (including azeotrope), not that it breaks some abv barrier a no-reflux column can't cross.a fractionating column (aka: stripping column; a packed column with out a reflux condensor) can produce a product that is 92%ABV, if run slowly enough

What is your source for this?the lower part of the column acts like a fractionating column and then there is a short section on top in which the reflux cycle occurs.

This is an important point. Finding the best balance point, or optimal compromise between various forces and requirements, is where the art of running a still lies.the tricky part is in removing product so that you don't upset the balance,

Be safe.

Be discreet.

And have fun.

Be discreet.

And have fun.

-

DestructoMutt

- Swill Maker

- Posts: 321

- Joined: Thu Jun 14, 2007 4:41 pm

- Location: Not that Vancouver, the original one.

Re: Thoughts on my reflux column design.

HookLine wrote:Interesting comments, DM. Got some questions/comments:

What would you say these variables are? column length, column diameter, heat input, heat extraction, atmospheric pressure, elevation, temperature, relative humidity, cooling water temperature, cooling water flow, packing type, packing density, packing consistency, column insulation, wash composition, type of heat input.....DestructoMutt wrote:the temperature gradient is something that occurs based on four or five variables

Are you saying that there is a 92% limit for a packed no-reflux column? AFAIK, in theory, a packed no-reflux column that is tall enough, and run slow enough, should deliver 95.6%, or very close. The point of returning reflux to the packed column is that it dramatically reduces the length of the column needed for a given column diameter, output rate, and purity (including azeotrope), not that it breaks some abv barrier a no-reflux column can't cross. no, yes a fractinonating column of infinite height and with infinite amount of heat input can achieve azeotrope, but for practical purposes a fractionating column is limited to about 92%ABV or less.a fractionating column (aka: stripping column; a packed column with out a reflux condensor) can produce a product that is 92%ABV, if run slowly enough

What is your source for this? Cox phase diagram for water ethanol mixtures based on %ABV vs. Temperature, and Mike Nixon's pages in the theory section of the parent site.the lower part of the column acts like a fractionating column and then there is a short section on top in which the reflux cycle occurs.

This is an important point. Finding the best balance point, or optimal compromise between various forces and requirements, is where the art of running a still lies. not if you know what your production rate is. which you must know if you are running a liquid management, or cooling management head. that way you can adjust take-off to a percentage of your production and have the correct reflux ratio. but with liquid management, the production rate diminishes as the run progresses, so you really should be cutting back on your take-off rate as the run progresses. whereas with VM the reflux ratio remains the same because it's separating the vapor into two streams.the tricky part is in removing product so that you don't upset the balance,

-

chunkystyles

- Novice

- Posts: 55

- Joined: Mon Aug 04, 2008 7:36 am

- Location: Arkansas

Re: Thoughts on my reflux column design.

My dad came in this weekend and brought me some new parts. I lost my fancy smartphone so I can't take pictures of it right now, but the valve is beastly. There is one problem, though. It is a 1.5 inch butterfly valve but the seal is nitrile rubber. He said they make teflon seals but he didn't have any. Until I find a teflon seal I doubt I will be running it.

Re: Thoughts on my reflux column design.

Well I read this page 4 or 5 times  .

.

Destructomutt

Do you know whether anyone has measured pressure at various points/levels in a column?

Destructomutt

Do you know whether anyone has measured pressure at various points/levels in a column?

-

chunkystyles

- Novice

- Posts: 55

- Joined: Mon Aug 04, 2008 7:36 am

- Location: Arkansas

-

DestructoMutt

- Swill Maker

- Posts: 321

- Joined: Thu Jun 14, 2007 4:41 pm

- Location: Not that Vancouver, the original one.

Re: Thoughts on my reflux column design.

why?airhill wrote:Do you know whether anyone has measured pressure at various points/levels in a column?

columns that use trays, sieves and plates develop pressure due to the fluid being retained on the trays, plates and sieves (head pressure).

our sytems, using scrubbers, don't generate pressure that is worth worrying about (the top of your column is open to the atmosphere isn't it?). yes, at the start, there is a pressure differential when the wash vapor which is denser than air, works its way up the column forcing the air out, but after that, you are left with a system that is purged of air, so the pressure becomes a constant throughout the system.

Re: Thoughts on my reflux column design.

Just curious

I am still trying to get my head round the fact that in the boiler and through the column you are having phase changes occuring with different mixtures on 'theoretical' plates.

When the phase change occurs you are having not only heat and one would assume a removal of heat but also molecules expanding the distance between them as they turn into a gas and at some point contracting the distance. As the column is changing its composition from bottom to top this is difficult to visulise.

As you say its an open ended system so flow would have been perhaps a better word.

I am still trying to get my head round the fact that in the boiler and through the column you are having phase changes occuring with different mixtures on 'theoretical' plates.

When the phase change occurs you are having not only heat and one would assume a removal of heat but also molecules expanding the distance between them as they turn into a gas and at some point contracting the distance. As the column is changing its composition from bottom to top this is difficult to visulise.

As you say its an open ended system so flow would have been perhaps a better word.

Re: Thoughts on my reflux column design.

Chunky, I have skimmed through this whole post and on seeing you first design I thought...turn the first condenser upside down (have it above the horizontal port), add a valve in the horizontal port, and you will have the finest VM still for miles around.

Glad to see you are on this track!

Glad to see you are on this track!

Last edited by Ayay on Thu Jul 23, 2009 1:45 am, edited 1 time in total.

cornflakes...stripped and refluxed

Re: Thoughts on my reflux column design.

Airhill, I got my head around it in this manner...It's the mingling of vapors going up and liquids going down. Vapors give water to the liquid and liquids give alcohol to the vapors. Latent heat is lost or gained with each transfer between vapor to liquid and liquid to vapor. A packed column holds up the liquids so that this transfer happens to the max.

Alcohol rich vapor arrives at the reflux condenser which condenses it and sends it down again as liquid, to be further stripped of water and enriched with alcohol. Over and over, until the alcohol is at the highest % possible at the top of the column. It will reach an equilibrium where it can't go any further and will keep trying anyway.

That's when you open the take-off valve just a tad, not enough to upset the equilibrium too much. The purest alcoholl will come out, and then it's a balance between equilibrium and out-put.

Alcohol rich vapor arrives at the reflux condenser which condenses it and sends it down again as liquid, to be further stripped of water and enriched with alcohol. Over and over, until the alcohol is at the highest % possible at the top of the column. It will reach an equilibrium where it can't go any further and will keep trying anyway.

That's when you open the take-off valve just a tad, not enough to upset the equilibrium too much. The purest alcoholl will come out, and then it's a balance between equilibrium and out-put.

cornflakes...stripped and refluxed

-

chunkystyles

- Novice

- Posts: 55

- Joined: Mon Aug 04, 2008 7:36 am

- Location: Arkansas

Re: Thoughts on my reflux column design.

Well, I'm back from another long hiatus. I haven't been able to run anything since last year and I finally got to run it about a week ago.

My still now stands at 8'8" total with exactly 4' of packing. I was going to get a picture of the whole setup, because it's awesome, but I had no camera. One thing I noticed is that the butterfly valve is not linear. When opened fully I was getting about 2L per hour and opened half way I was getting about 500ml per hour. That would mean that at half open I'm getting 8:1 reflux ratio. At this rate I was getting 93% but the temp was probably about 50-60F so that would add about...1.5-1%? I don't have my hydrometer on me so I can't test it right now, I will be doing that later this week. What is strange to me is that the temperature at the split stayed completely steady for the entire run at right around 169F and the temperature in the middle of the column stayed steady at 171ish F. It stayed there until the tails came through. I was under the impression that I should see a temperature spike when the heads where done. I don't really think I got rid of the heads from the hearts because there is a sweet flavor to it. This is better than my last batch though and is definitely better than store-bought. I'm still not very good at tasting the heads/hearts cuts because I couldn't tell much of a difference throughout the run, up until the tails.

One question I have is what should I be running, reflux ratio wise, with a 4 feet of 3 inch packed column? Right now I am really limited by my cooling. My condensers and my lines leading to the condensers cause a lot of friction and I cannot get enough water through them to be able to run my heating at anything but about 1/8 power(guessing). At that rate I was getting 2L per hour with a 2:1 reflux ratio. I would assume that if I could cool better and use more heat I could get more output at the same quality.

Something else that worried me was that I kept seeing very small, very low velocity puffs of what I assume was vapor coming out of the product output. Above the first condenser was open to air, so it shouldn't have been from pressure build up, especially since there shouldn't be any after equalization anyway. The product condenser was only hot on the top 1/2 or so and the bottom was nice and cold. The product was coming out nice and cool as well, probably 50-60F.

Any thoughts, suggestions, or questions welcome. I'm still trying to wrap my head around all of this stuff.

My still now stands at 8'8" total with exactly 4' of packing. I was going to get a picture of the whole setup, because it's awesome, but I had no camera. One thing I noticed is that the butterfly valve is not linear. When opened fully I was getting about 2L per hour and opened half way I was getting about 500ml per hour. That would mean that at half open I'm getting 8:1 reflux ratio. At this rate I was getting 93% but the temp was probably about 50-60F so that would add about...1.5-1%? I don't have my hydrometer on me so I can't test it right now, I will be doing that later this week. What is strange to me is that the temperature at the split stayed completely steady for the entire run at right around 169F and the temperature in the middle of the column stayed steady at 171ish F. It stayed there until the tails came through. I was under the impression that I should see a temperature spike when the heads where done. I don't really think I got rid of the heads from the hearts because there is a sweet flavor to it. This is better than my last batch though and is definitely better than store-bought. I'm still not very good at tasting the heads/hearts cuts because I couldn't tell much of a difference throughout the run, up until the tails.

One question I have is what should I be running, reflux ratio wise, with a 4 feet of 3 inch packed column? Right now I am really limited by my cooling. My condensers and my lines leading to the condensers cause a lot of friction and I cannot get enough water through them to be able to run my heating at anything but about 1/8 power(guessing). At that rate I was getting 2L per hour with a 2:1 reflux ratio. I would assume that if I could cool better and use more heat I could get more output at the same quality.

Something else that worried me was that I kept seeing very small, very low velocity puffs of what I assume was vapor coming out of the product output. Above the first condenser was open to air, so it shouldn't have been from pressure build up, especially since there shouldn't be any after equalization anyway. The product condenser was only hot on the top 1/2 or so and the bottom was nice and cold. The product was coming out nice and cool as well, probably 50-60F.

Any thoughts, suggestions, or questions welcome. I'm still trying to wrap my head around all of this stuff.

Re: Thoughts on my reflux column design.

Hi Chunky, I have found with my VM, that there is not much happening temperature-wise during a run. I dont even look at it any more, except to see when the temps are up the column.

I cut by smell and taste, hoping to get better at it..

I have had problems with the puffs as well, seems vapor can fall straight down without condensing, so I put a copper coil into my liebig to add turbulence, fixed that problem completely. Otherwise a bit of scrubber can help too.

Cheers

I cut by smell and taste, hoping to get better at it..

I have had problems with the puffs as well, seems vapor can fall straight down without condensing, so I put a copper coil into my liebig to add turbulence, fixed that problem completely. Otherwise a bit of scrubber can help too.

Cheers

-

chunkystyles

- Novice

- Posts: 55

- Joined: Mon Aug 04, 2008 7:36 am

- Location: Arkansas

Re: Thoughts on my reflux column design.

Both of my condensers are coils, so that helps I guess. I will try some copper mesh next time. I considered that, but I was already all set up and running so it was too late.plonker wrote:Hi Chunky, I have found with my VM, that there is not much happening temperature-wise during a run. I dont even look at it any more, except to see when the temps are up the column.

I cut by smell and taste, hoping to get better at it..

I have had problems with the puffs as well, seems vapor can fall straight down without condensing, so I put a copper coil into my liebig to add turbulence, fixed that problem completely. Otherwise a bit of scrubber can help too.

Cheers

Re: Thoughts on my reflux column design.

it takes very little to induce turbulence. a single strand of wire with a few bends in it should be enough. The bends will help hold it in place.

The butterfly valve will have an opening more or less equal to the sine of the angle of the valve if 0 degrees is closed - subject to the geometry of the rest of the VM setup. My 3/4" ball valve is starting to open at 10 degrees and it never needs to be open more than 25- 35 degrees. More than that and the % abv drops too much.

The butterfly valve will have an opening more or less equal to the sine of the angle of the valve if 0 degrees is closed - subject to the geometry of the rest of the VM setup. My 3/4" ball valve is starting to open at 10 degrees and it never needs to be open more than 25- 35 degrees. More than that and the % abv drops too much.

Time's a wasting!!!