Heating Element Control

Moderator: Site Moderator

Re: Heating Element Control

My ammeter works great and I did a nice boil on my batch of beer yesterday.

This is going to make it nice to dial in on a run.

This is going to make it nice to dial in on a run.

Re: Heating Element Control

meh... if you've read and didn't find, no shame on you at all.idopewars wrote:Here I am, new member only writing my second post and already I'm asking for stuff... shame on me.

Anyway, does anyone happen to have a PCB template for a diac/triac based controller? I figure since I need a controller, I might as well build one from scratch. As long as I'm doing that, I might as well as well put it on a PCB... and hey, why not make my own board as well? I can knock together a template of my very own, but I'm not a Windoze user so my design software options appear to be quite limited. I suppose any drawing program will work, if it comes to it, but if someone's got a ready-made solution for a template... well, I'm not that committed to doing everything myself.

I used the board right out of an old power supply... if you dont have a blown up PC power supply laying around, ask at Best Buy or your local computer shop if they have any that they've recently pulled. Often they will come with fans and for sure it will have heat sinks in it. If you get TO220 case triacs, then you can pretty much use the heat sink on the board where it was intended to be used, and mount the triac to the circuit board where an opamp was previously mounted. If you want to use a 12 volt fan, you'll need to find a small 12VDC wall blister to wire inside your controller box.

The only issue of concern is the traces on the existing board. Get your exacto knife out and cut everything that the triac is wired to, remove the traces from the existing board - they will peel off quite easily if you get under the cut end with an exacto blade.

Making a template for a PCB is quite easy, but it depends entirely on the size of the board and the size of the box you need. Back in my early days, I used to make PC board negatives with mylar and black tape on a light table. To actually make a board, you need the mylar negative, a silk screen of the negative (which involves an entirely separate set of complicated processes), single or double sided copper coated fiberglass cut to your box, coat the board with emulsifier using the silk screen, expose the board to UV to burn an image into the emulsion, etch away the non-emulsified copper in an acid bath, and drill and tin your board.

You are better off salvaging and repurposing an old PC power supply. If you are lazy, you can even hit the board with your propane torch lightly to melt the solder off the components. Hit it with flame and rap it on the workbench and watch the small parts fall out! LOL (the voice of experience)

Greed is a great hurdle to overcome when it comes to making a quality drink! - Bushman

Re: Heating Element Control

Take it form someone who has made more than a handful of PCB's over the years that it's not as easy as you're making it sound... And for entry level PCB's you'd be better off doing hand layout... If someone has very limited electronics experience the task can be quite daunting... And the investment in materials to make a board, even using free software, is costly and time consuming... And I surely wouldn't advise anyone to make a mains voltage PCB as their first attempt... Not to mention the need to learn about handling and disposing of yet another caustic chemical... The investment adds up rapidly and adds yet another complex hobby into the mix...Klaxxon wrote:Making a template for a PCB is quite easy, but it depends entirely on the size of the board and the size of the box you need. Back in my early days, I used to make PC board negatives with mylar and black tape on a light table. To actually make a board, you need the mylar negative, a silk screen of the negative (which involves an entirely separate set of complicated processes), single or double sided copper coated fiberglass cut to your box, coat the board with emulsifier using the silk screen, expose the board to UV to burn an image into the emulsion, etch away the non-emulsified copper in an acid bath, and drill and tin your board.

Truth be known, the simplest of controllers don't require a PCB at all... The few components required can be fastened together and mounted in such a way that anyone who can solder would be capable of completing a basic controller in an evening... Or, for a more complex one-off board, using an inexpensive single sided copper clad prototyping board would be the way to go...

Unless you are into electronics, or just have money to burn, you'd be further ahead purchasing a controller than attempting to build one... Food for thought...

Re: Heating Element Control

Sounds like mighty reasonable advice. I was thinking of putting together a 240 controller myself (planning on running a single 4500w). I'm sorta handy with a soldering iron, so I'm sure I could pull off a simple circuit like this. Never built anything for 240 tho. Wonder if I could pick up one of those eBay units and replace the triac with one that can handle more power. Seems they only go up to 3800w max, but the price is right.rad14701 wrote:Unless you are into electronics, or just have money to burn, you'd be further ahead purchasing a controller than attempting to build one... Food for thought...

Re: Heating Element Control

+1 to what rad said...

i certainly oversimplified it. it took me three or four to for days to make one batch of a dozen PC boards when i was doing it for a living - i worked in a mom and pop electronics shop, so the method i used would approximate the method a home user would also have to work with... its a ton of work for what you get out of it

i certainly oversimplified it. it took me three or four to for days to make one batch of a dozen PC boards when i was doing it for a living - i worked in a mom and pop electronics shop, so the method i used would approximate the method a home user would also have to work with... its a ton of work for what you get out of it

Greed is a great hurdle to overcome when it comes to making a quality drink! - Bushman

Re: Heating Element Control

Here's one for Rad and the other pros around...

Would this:

http://www.newark.com/jsp/search/produc ... KU=96K6587

Perform the same as the PSR-25 made up as members have been doing...it has a good enough pot and the required heatsink and seems to have same ratings (I was expecting it to say that it was a PSR-25 inside)...

It's cheaper than buying all the parts for me in Australia and without the effort!

Cheers Guys.

Would this:

http://www.newark.com/jsp/search/produc ... KU=96K6587

Perform the same as the PSR-25 made up as members have been doing...it has a good enough pot and the required heatsink and seems to have same ratings (I was expecting it to say that it was a PSR-25 inside)...

It's cheaper than buying all the parts for me in Australia and without the effort!

Cheers Guys.

Re: Heating Element Control

Brendan, that appears to be an all-in-one controller unit and should work without any modifications...

Re: Heating Element Control

Thanks Rad,

Planning to use it with:

http://www.newark.com/united-automation ... t=F175-25a

to deal with RF interference.

It's a bit of money, but I figure done right the first time, should never have an issue. Considering it affects both safety, and product quality...

Planning to use it with:

http://www.newark.com/united-automation ... t=F175-25a

to deal with RF interference.

It's a bit of money, but I figure done right the first time, should never have an issue. Considering it affects both safety, and product quality...

Re: Heating Element Control

These are my basic instructions for a simple "el cheapo" controller, my one has been serving me well. Thought it was only fair that I share considering how far the info on this site has gotten me. Hope it can help a couple of ppl.

Panda wrote: Purchase one of these relays depending on the size of your stills element;

http://www.uxcell.com/search.php?catego ... ctSearch=1

If the relay you select does not come with a Heat sink, purchase one of these 2;

http://www.uxcell.com/black-metal-heat- ... 39013.html

http://www.uxcell.com/aluminum-heat-sin ... 31981.html

Purchase one of the following Voltmeters;

Europe, Australia, NZ ect.http://www.uxcell.com/85l1-0250v-rectan ... 32018.html

USA....http://www.uxcell.com/ys50-0150v-analog ... 36483.html

Purchase a Type B linear 3pin potentiometer that meets the requirements of your selected relay, you will find one between Uxcell and ebay cheap.

Purchase some thermal compound (heat sink goo) from ebay to smear between the the heat sink and relay. I got 3 syringes for $1 and only needed half a syringe.

Put together as shown;

I feel sorry for people who don't drink. When they wake up in the morning, that's as good as they're going to feel all day. ~Frank Sinatra

-

freespirited

- Swill Maker

- Posts: 258

- Joined: Thu Jan 13, 2011 2:49 pm

Re: Heating Element Control

Heres what i used for my 15.5 gallon keg in the US:

1-SS bung (sorry forget thread pitch) McMaster-Carr

1-4500w low incoloy element w/ protective coating for water with high mineral content $23 Wholesale plumbing

1 metal junction box w/ plastic cover $4

1 Aubur PID syl-2365 w/ k thermocouple $38 EBAY

1-40A SSR w/ heat sink $12

2- 4 prong 30A dryer cord scrapyard $10 for both. I cut the plug off one and used it for the lead between the keg and pid housing, since it has a rubber coating.

1-110v computer fan $10 Ebay

1-8x8x8" plastic junction box $5 Ebay

Heats a 12 gallon charge in 35-45 minutes (results may vary depending on insulation. I only insulated my column), runs at 45% in manual mode (again results may vary). SSR in the box w/ fan runs at a steady 125*F on full power

I would also recommend a 220v 30A twist lock plug and spark protective recepticle @ the keg for easy cleaning. Along with a 110v switch mounted to the box so the pid doesn't cause the 220v plug to spark when plugged in.

THis may be cheaper than most controllers it may also be more than some. However, there are no annoying noises (click click click) no lights dimming and if something breaks your only out a small portion of the cost of the build.

If someone wants a wiring dia or me to build them one send me a pm.

1-SS bung (sorry forget thread pitch) McMaster-Carr

1-4500w low incoloy element w/ protective coating for water with high mineral content $23 Wholesale plumbing

1 metal junction box w/ plastic cover $4

1 Aubur PID syl-2365 w/ k thermocouple $38 EBAY

1-40A SSR w/ heat sink $12

2- 4 prong 30A dryer cord scrapyard $10 for both. I cut the plug off one and used it for the lead between the keg and pid housing, since it has a rubber coating.

1-110v computer fan $10 Ebay

1-8x8x8" plastic junction box $5 Ebay

Heats a 12 gallon charge in 35-45 minutes (results may vary depending on insulation. I only insulated my column), runs at 45% in manual mode (again results may vary). SSR in the box w/ fan runs at a steady 125*F on full power

I would also recommend a 220v 30A twist lock plug and spark protective recepticle @ the keg for easy cleaning. Along with a 110v switch mounted to the box so the pid doesn't cause the 220v plug to spark when plugged in.

THis may be cheaper than most controllers it may also be more than some. However, there are no annoying noises (click click click) no lights dimming and if something breaks your only out a small portion of the cost of the build.

If someone wants a wiring dia or me to build them one send me a pm.

-

astronomical

- Rumrunner

- Posts: 683

- Joined: Fri Nov 18, 2011 4:54 pm

Re: Heating Element Control

Wow panda.. You beat me by two posts... LMFAO!!!!!!!!!!! just realized it now.. haaaaaaaaaaaaaaaaaaaaaa.. Glad to hear its working well.. Time for me to pull the trigger..

http://www.ebay.com/itm/SSVR-25VA-Resis ... 3a6e48b9ea" onclick="window.open(this.href);return false;" rel="nofollow

would this work like a PSR-25 but use a different sized pot?

Or this http://www.ebay.com/itm/470-560K-ohm-SS ... 231797f97a" onclick="window.open(this.href);return false;" rel="nofollow

"Fotek SSR-40VA, for example, has built-in zero-crossing switching.

Now, switching at the zero-crossing is a VERY DESIRABLE trait for 98% of all SSR applications because it results in very "clean" operation with no switching hash. But it completely prevents fine-grain proportional control. Unless you are talking about something like a heating element, etc. There, you can simply control the proportion in steps of 16.667ms (for 60HZ) or 20ms (for 50Hz). But, as you say, NOT appropriate for light dimming, whether incandescent or LED or fluorescent, or whatever.

"

Im surprised that after doing several google searches of this site NOBODY has mentioned these by the terms "fotek", "ssvr", etc... This being censored or what? Theres a lot of hits just using google and people even talking of using it with stilling and heating elements.

More rresearch.

More info on relay

http://www.ebay.com/itm/SSVR-25VA-Resis ... 3a6e48b9ea" onclick="window.open(this.href);return false;" rel="nofollow

would this work like a PSR-25 but use a different sized pot?

Or this http://www.ebay.com/itm/470-560K-ohm-SS ... 231797f97a" onclick="window.open(this.href);return false;" rel="nofollow

"Fotek SSR-40VA, for example, has built-in zero-crossing switching.

Now, switching at the zero-crossing is a VERY DESIRABLE trait for 98% of all SSR applications because it results in very "clean" operation with no switching hash. But it completely prevents fine-grain proportional control. Unless you are talking about something like a heating element, etc. There, you can simply control the proportion in steps of 16.667ms (for 60HZ) or 20ms (for 50Hz). But, as you say, NOT appropriate for light dimming, whether incandescent or LED or fluorescent, or whatever.

"

Im surprised that after doing several google searches of this site NOBODY has mentioned these by the terms "fotek", "ssvr", etc... This being censored or what? Theres a lot of hits just using google and people even talking of using it with stilling and heating elements.

More rresearch.

More info on relay

-

astronomical

- Rumrunner

- Posts: 683

- Joined: Fri Nov 18, 2011 4:54 pm

Re: Heating Element Control

15% off code for newark NEW2P. Good until January 31st. Unlimited uses.. Enjoy!

__________________________

We appreciate your business and would like you to have a 15% off voucher. Your code is NEW2P, please use this when placing your orders (see Exclusion at the bottom). Please share this voucher with your co-workers and utilize the voucher as many times as you like through January 31st, 2012.

I hope you'll take advantage of this special offer.

__________________________

We appreciate your business and would like you to have a 15% off voucher. Your code is NEW2P, please use this when placing your orders (see Exclusion at the bottom). Please share this voucher with your co-workers and utilize the voucher as many times as you like through January 31st, 2012.

I hope you'll take advantage of this special offer.

- crazyk78

- Swill Maker

- Posts: 316

- Joined: Sat Jun 19, 2010 9:39 pm

- Location: Ozzie Ozzie Ozzie Oi Oi Oi

Re: Heating Element Control

Hi guys,

Can I use a 2W, 1Mohm potentiometer with my PSR-25 or does it need to be a 500KOhm ?

Thanks

Can I use a 2W, 1Mohm potentiometer with my PSR-25 or does it need to be a 500KOhm ?

Thanks

-

MuleKicker

- retired

- Posts: 3111

- Joined: Sun Jun 14, 2009 2:14 pm

- Location: If I told you, I'd have to Kill You.

Re: Heating Element Control

That should work fine, just take more turning of the knob to get an output change.crazyk78 wrote:Hi guys,

Can I use a 2W, 1Mohm potentiometer with my PSR-25 or does it need to be a 500KOhm ?

Thanks

-Control Freak-

AKA MulekickerHDbrownNose

AKA MulekickerHDbrownNose

- crazyk78

- Swill Maker

- Posts: 316

- Joined: Sat Jun 19, 2010 9:39 pm

- Location: Ozzie Ozzie Ozzie Oi Oi Oi

Re: Heating Element Control

Cheers, thanks Mule

What about a 470K ohm would that be ok?

Got some cheap ones on ebay

http://www.ebay.com.au/itm/2pcs-WTH118- ... 1e64745fdd" onclick="window.open(this.href);return false;" rel="nofollow

What about a 470K ohm would that be ok?

Got some cheap ones on ebay

http://www.ebay.com.au/itm/2pcs-WTH118- ... 1e64745fdd" onclick="window.open(this.href);return false;" rel="nofollow

Re: Heating Element Control

The tolerance on that potentiometer on the low side is between 423,000 ohms to 517,000 ohms, it's a crap shoot on what it really may be until you actually put it under measure. Unless the specs calls for a tolerance of less than 10% it should be good to go, I doubt it will have much of an impact in this application.crazyk78 wrote:Cheers, thanks Mule

What about a 470K ohm would that be ok?

Got some cheap ones on ebay

http://www.ebay.com.au/itm/2pcs-WTH118- ... 1e64745fdd" onclick="window.open(this.href);return false;" rel="nofollow

A 500,000 ohm pot @ 10% would range from 450,000 to 550,000 and many are 20% giving a 400k to 600k range.

Re: Heating Element Control

The range of the potentiometer is what controls how far down you can throttle the power... On the low end you have zero resistance through the potentiometer... On the high end you are only concerned with how much it reduces the power... It is rare that you would need the potentiometer to totally stop producing power altogether... In fact some controller designs even discuss optimizing the circuit to have a specified low end by adding a resistor in parallel... At the price and ease of swapping out or optimizing just go with what you can get...

-

calicojack

- Novice

- Posts: 32

- Joined: Tue Nov 16, 2010 7:27 am

Re: Heating Element Control

as i'm going to need a controller soon i'm going to throw this out there:

for those of us who don't have the patience to read through 60 pages of this will work, but you can use this too, or try this option and hook it to this option, no wait here's a better option to hook it to:

The next time one of you expierenced builders decides to put together a controller could you post a parts list and then do a step by step pictorial on how to assemble all the parts, post it and make it a sticky?

for those of us who don't have the patience to read through 60 pages of this will work, but you can use this too, or try this option and hook it to this option, no wait here's a better option to hook it to:

The next time one of you expierenced builders decides to put together a controller could you post a parts list and then do a step by step pictorial on how to assemble all the parts, post it and make it a sticky?

-

MuleKicker

- retired

- Posts: 3111

- Joined: Sun Jun 14, 2009 2:14 pm

- Location: If I told you, I'd have to Kill You.

Re: Heating Element Control

how about ya check the lounge jack? its already done.

-Control Freak-

AKA MulekickerHDbrownNose

AKA MulekickerHDbrownNose

-

troubadeer

- Novice

- Posts: 6

- Joined: Mon Dec 12, 2011 2:54 pm

Re: Heating Element Control

I don't trust myself to build one myself yet, as there's no complete walkthrough that i've seen, so I was thinking of going the route of a variac (or something you built ) as my control element, for a slightly costlier, albeit safer approach. I'm a ME, not EE. Lost, but not hopeless.

My still:

15 Gal keg, looking to run a 120V household socket to a 1,500 W heater element. 28 inch packing raschig rings, 2 inch diameter pipe. Possibly going to bring it up to temp with propane, and switch over to voltage to get accurate heat control.

My math:

P=I*V --------- I=P(W)/V(V)

1500W/120V= 12.375A

I read somewhere along the line that you should double the amperage in a heater circuit=24.75 A, however, I can only find 20 A max for a reasonable price. Is this acceptable? I don't want to cut corners, or light my shed on fire.

My questions:

1. what's the best way to run this thing? I'm not looking to blow a ton of money, but I found 20A variacs on ebay

http://www.ebay.com/sch/i.html?_nkw=variac+20+amp" onclick="window.open(this.href);return false;" rel="nofollow

2. hillbillystills mentioned a GFCI was necessary. That drives up the price quite a bit, but is it needed for a variac?

Many thanks.

My still:

15 Gal keg, looking to run a 120V household socket to a 1,500 W heater element. 28 inch packing raschig rings, 2 inch diameter pipe. Possibly going to bring it up to temp with propane, and switch over to voltage to get accurate heat control.

My math:

P=I*V --------- I=P(W)/V(V)

1500W/120V= 12.375A

I read somewhere along the line that you should double the amperage in a heater circuit=24.75 A, however, I can only find 20 A max for a reasonable price. Is this acceptable? I don't want to cut corners, or light my shed on fire.

My questions:

1. what's the best way to run this thing? I'm not looking to blow a ton of money, but I found 20A variacs on ebay

http://www.ebay.com/sch/i.html?_nkw=variac+20+amp" onclick="window.open(this.href);return false;" rel="nofollow

2. hillbillystills mentioned a GFCI was necessary. That drives up the price quite a bit, but is it needed for a variac?

Many thanks.

-

MuleKicker

- retired

- Posts: 3111

- Joined: Sun Jun 14, 2009 2:14 pm

- Location: If I told you, I'd have to Kill You.

Re: Heating Element Control

If your running in your shed, you should have access to 220v? Run a 220 30 a circuit and you would be golden.

-Control Freak-

AKA MulekickerHDbrownNose

AKA MulekickerHDbrownNose

-

MuleKicker

- retired

- Posts: 3111

- Joined: Sun Jun 14, 2009 2:14 pm

- Location: If I told you, I'd have to Kill You.

Re: Heating Element Control

There is a link in the lounge of the exact pot you need. Strait from Newark, they work great. Cheap too.crazyk78 wrote:Cheers, thanks Mule

What about a 470K ohm would that be ok?

Got some cheap ones on ebay

http://www.ebay.com.au/itm/2pcs-WTH118- ... 1e64745fdd" onclick="window.open(this.href);return false;" rel="nofollow

-Control Freak-

AKA MulekickerHDbrownNose

AKA MulekickerHDbrownNose

-

calicojack

- Novice

- Posts: 32

- Joined: Tue Nov 16, 2010 7:27 am

Re: Heating Element Control

this. but i guess since folks wouldn't pay $325 for a tutorial it won't get done.troubadeer wrote:I don't trust myself to build one myself yet, as there's no complete walkthrough that i've seen, so I was thinking of going the route of a variac (or something you built ) as my control element, for a slightly costlier, albeit safer approach. I'm a ME, not EE. Lost, but not hopeless.

Last edited by calicojack on Sat Jan 14, 2012 8:14 pm, edited 1 time in total.

-

MuleKicker

- retired

- Posts: 3111

- Joined: Sun Jun 14, 2009 2:14 pm

- Location: If I told you, I'd have to Kill You.

Re: Heating Element Control

If your looking for someone to hold your hand and build it for you, forget it. The folks here donate ther time, and I think there is some pretty damn good info. If you can't build one based on the info I've put in the lounge, you shouldn't be doing it in the first place. Whinning about it isn't going to get you any points either.

Last edited by MuleKicker on Sun Jan 15, 2012 7:02 pm, edited 1 time in total.

-Control Freak-

AKA MulekickerHDbrownNose

AKA MulekickerHDbrownNose

Re: Heating Element Control

My god I hope ‘ME’ doesn’t mean Mechanical Engineer if so we (the citizens of the world) have real problems.troubadeer wrote:.....I don't trust myself to build one myself yet, as there's no complete walkthrough that i've seen.....I'm a ME, not EE…..Lost.....

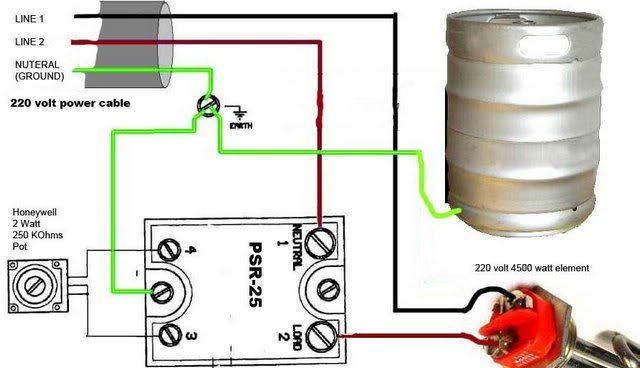

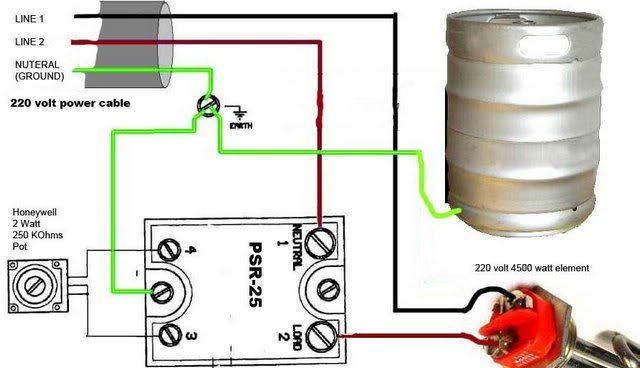

Although the ‘Heating Element Control’ thread is rather extensive (60 + pages) but in this thread there is information/diagram for a PSR-25 based Phase Angle Controller. Refer to Forum Member snideman Sun Jul 18, 2010 6:57AM posting (page 32) which depicts 120v wiring and Forum Member Panda Sun Jan 01, 2012 8:54AM posting (page 59) which depicts 220v wiring. If a ‘ME’ (Mechanical Engineer) can’t figure out how to build his own Heating Element Controller from the information presented in this thread I have to question what our colleges are learning our Engineers these days.

Regards,

Coaster

-

calicojack

- Novice

- Posts: 32

- Joined: Tue Nov 16, 2010 7:27 am

Re: Heating Element Control

i know that wasn't directed at me, but jeez this board is unfriendly.Coaster wrote:My god I hope ‘ME’ doesn’t mean Mechanical Engineer if so we (the citizens of the world) have real problems.troubadeer wrote:.....I don't trust myself to build one myself yet, as there's no complete walkthrough that i've seen.....I'm a ME, not EE…..Lost.....

Although the ‘Heating Element Control’ thread is rather extensive (60 + pages) but in this thread there is information/diagram for a PSR-25 based Phase Angle Controller. Refer to Forum Member snideman Sun Jul 18, 2010 6:57AM posting (page 32) which depicts 120v wiring and Forum Member Panda Sun Jan 01, 2012 8:54AM posting (page 59) which depicts 220v wiring. If a ‘ME’ (Mechanical Engineer) can’t figure out how to build his own Heating Element Controller from the information presented in this thread I have to question what our colleges are learning our Engineers these days.

Regards,

Coaster

-

irishcarbomb

- Novice

- Posts: 12

- Joined: Wed Dec 28, 2011 9:09 pm

- Location: Houston, TX

Re: Heating Element Control

I've read through all 60 pages about 3 times now. I just want to make sure Ive got the right idea since the 4 wire US 240V only came up once or twice, and maybe help someone down the road.

There were a few "I don't understand the squiglies" so I thought this might make it a bit easier for some folks to understand as well as double check my logic.

There were a few "I don't understand the squiglies" so I thought this might make it a bit easier for some folks to understand as well as double check my logic.

Last edited by irishcarbomb on Mon Jan 16, 2012 8:22 pm, edited 1 time in total.

Re: Heating Element Control

irishcarbomb, that looks alright to me...

-

calicojack

- Novice

- Posts: 32

- Joined: Tue Nov 16, 2010 7:27 am

Re: Heating Element Control

probably the easiest diagram to follow that i've found (on another site)

-

MuleKicker

- retired

- Posts: 3111

- Joined: Sun Jun 14, 2009 2:14 pm

- Location: If I told you, I'd have to Kill You.

Re: Heating Element Control

I think its worth noting. I have seen a few of these sketches, (like irishcarbombs) that have the 25A SSR in it. If you are using a simlple SSR, that circuit will not work. You need to use a psr module (as in jacks sketch) if you want to connect a pot directly to the module.

-Control Freak-

AKA MulekickerHDbrownNose

AKA MulekickerHDbrownNose