Yeast

Yeast

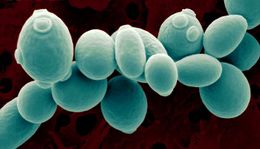

Yeast a single celled organism capable of fermenting carbohydrates and responsible for changing sugar to alcohol in the fermentation process.

The most common yeast used in alcohol production is Saccharomyces cerevisiae. According to The Alcohol Textbook this yeast has been used to produce 23.8% ABV in "batch fermentation with all carbohydrate provided at the start of fermentation." (Ingledew, p. 76.) There are several yeast strains available to suit virtually any type of beverage alcohol production.

There are several factors that can cause yeast distress.

Dry Yeast

Dry yeast should be rehydrated (aka Proofed) before use. This ensures viability.

- Put 1 cup water and one teaspoon of sugar or a tablespoon of wort into a sanitized jar and boil shortly. A microwave is fine for this.

- Cover with saran wrap and wait until cooled to 95-105F (35-40C).

- Pitch (stir) in the yeast. Recover with Saran Wrap. place in a warm area out of direct sunlight.

After 30 minutes or so the yeast should be visibly churning and/or foaming, and is ready to pitch.

Liquid Yeast

Liquid yeast can be pitched without any preparation for smaller batches. "Smack Packs" contain yeast and nutrients and also can be pitched directly without extra preparation.

Yeast Starter

A media in which yeast is activated and encouraged to multiply to a high density so that when added to a wash, wort or must it will have a better chance of populating successfully. It is also used to decrease fermentation time. By pitching more yeast it takes less time to fully ferment the wash and reduces the chance for infection. Above just rehydrating yeast, a yeast starter is used to kick start fermentation. They are also used in larger batch processing as it is less expensive to create a starter than buy the correct amount of yeast.

Do I need to add additional nutrients?

It depends on the raw material you are using to ferment. For all grain/extract brewing, Molasses and fruit you generally won't need them. A small amount will help to get things going or speed things along. For crystallized and other sugar variants that don't contain much molasses it should be considered a requirement. It would also be good to use a buffer to control pH levels. Sugarheads have a reputation of rapid acidification causing stuck ferments.

Yeast Bomb

A Yeast Bomb is a mixture of extra nutrients to increase fermentation speed. The nutrients are not added until the yeast is pitched. The B vitamins increases the activity of the yeast. The boiled yeast hulls and other ingredients provide nutrients needed for aggressive growth. This is added to the wash at the same time as the yeast is.

From the Pugirum thread:

- 2 vitamin B, crushed with mortar and pestle

- 5 teaspoons of 20-0-0, agricultural fertilizer

- 1/4 teaspoon of epsom salt

- 1/4 cup bakers yeast

- 1 gallon water

- Boil all for 15 minutes and strain.

Yeast Nutrient Mix

Should you want to make your own batch of yeast nutrients though; the following recipe will provide you with a relatively potent mixture. The result will be a mixture of approximately 800g of Nutrients, of which you only need to add 3 to 5 grams per 20lt fermentation.

- 40g of Di-Ammonium Phosphate (AKA DAP)

- 747g of Ammonium Sulphate

- 2g of Thiamine (Vitamin B1)

- 1g of Potassium Tartrate

- 10g of Bentonite

Sourced from Distillique: How to make your own Yeast Nutrient

Creating a fruit based Yeast Starter

There are several ways to make a starter. To make a really vigorous starter for inoculating a must initially or restarting a stuck fermentation, in a quart jar dissolve 1 teaspoon of sugar and 1/8 teaspoon of yeast nutrient in 1 cup of warm water (less than 104°F.). To this, add 1/4 cup of the juice from the must to be fermented. Sprinkle 1 packet of active dry yeast on the surface of the liquid. Do not stir. Cover the jar with a paper towel or napkin held in place with a rubber band. Wait for the yeast to become active. This could become obvious in as little as 15 minutes or could take as long as 2-4 hours. If no evidence of activation in 4 hours, the yeast was too old or dead from exposure to temperature extremes (usually heat, but possibly extreme cold). In such a case, sprinkle another packet of yeast into same jar and recover. When yeast (first or second sachet) is evidently active, add another 1/4 cup of juice from the must and recover.

Wait until vigorous activity returns (usually 30-90 minutes) and add another 1/4 cup of juice. When again vigorously active, add yet another 1/4 cup of juice. Wait 1-2 hours and gently pour half the liquid over the surface of the must. Do not stir. The idea is for the starter to remain on or close to the surface where there is plenty of air for the yeast to "breath." Cover the primary fermentation vessel with a sanitized cloth or sheet of plastic. After 2-4 hours, the surface of the must should have small bubbles rising from fermentation or a healthy layer of yeast culture. Stir shallowly and recover the primary. Wait another 2-4 hours and fermentation should be more vigorous. Add the remainder of the starter and stir deeply. Recover primary. If the starter does not produce a vigorous fermentation in the primary, add another 1/4 cup of juice to the reserved half of the starter media. Wait 2 hours and add yet another 1/4 cup of juice. This starter is now 2 parts juice and 1 part water. When this is fermenting vigorously, add half of it to the must as before and try again.

HD Posts

- Yeast Starter/Yeast Bomb thread on Home Distiller

- Pugirum's Yeast Bomb Thread

- More than you ever wanted to know about yeast

- More than you ever wanted to know about yeast Part 2

- Free Amino Nitrogen (FAN) usage by various yeasts

External Links

- Creating a yeast starter for beer/whiskey

- Yeast Nutritional Needs

- How to brew: Yeast Starters

- Genetics.org's Yeastbook - a collection of papers on many aspects of yeast.

- White Labs Yeast Company

- Mr Malty Yeast Starter FAQs

- Distillique: How to make your own Yeast Nutrient

- Homebrewer's Association: How to make a yeast starter