Last night I decided to try and remove the interior section of the 1" through pipe but could not figure out how to do it with the tools I had. So I took apart the head and made a new one with a butt joint.

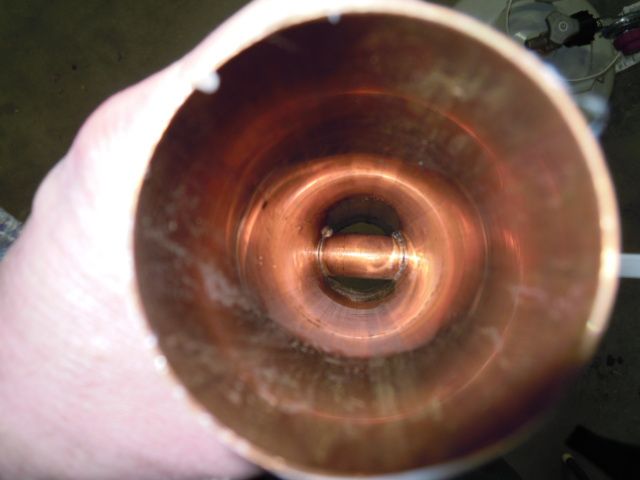

This pic shows the interior, which has not been cleaned yet.

and here is a close up of the soldering at the joint. Not pretty but I was trying to build up the solder and found it a little difficult to do. I think this might be strong enough, as I grabbed the head in one hand and rested the bend on my belly, while pulling the end of the downpipe and the top of the head towards me at the same time. Essentially trying to get the joint to break. Even with quite a bit of pressure it did not bend, crack or give any indication of potential failure.

Maritimer:

Thanks for the cad drawing - that clearly shows what you did and I'm sure that would be a rock solid structure.

Usge:

The Compleat Distiller shows a VM design that includes a 1" x 1" x 1" tee between the top of the column and the bottom of the head. From what I have read in other threads here and info in the Compleat Distiller the take off size is not important but the minimum size that the vapour sees on the discharge size is. There seems to be some disagreement about this issue. So I decided to go with a design that has proven to produce what I am after; pure azeotrope at 1l per minute. Maritimers setup does this so I figured I would follow his design, which has a 1" takeoff from a 2" column. Once I get this new head finished (I still need to add the therm port on the take off line) then I can try running with more heat. Maritimer pointed out that my therm placement may have had something to do with the fluctuating temps I was getting.

The fiddly part of the Boka is the damn brass needle valve. The settings change as the valve heats up and if you are not watching it like a hawk the discharge flow will suddenly increase drastically. This can and likely would screw up the column equilibrium if it is not caught as it happens. It usually takes several adjustments to get the final setting. I also found that if I lift up on the valve stem or push down on it the flow will change. The valve is also stiff to turn when it is cold and very loose once it heats up. Probably should have gone with a stainless valve. I think I have the Boka tuned in but maybe not. Once I start taking off the hearts the temp usually sits rock solid at 169.2 while I take off 1l per hour and when I hit the tails the temp will bump up 0.2* then start to climb. I am at about 2700' elevation so boiling temps are lower here. Maybe after I move the therm on the VM I will get more constant temp readings too. Time will tell.

Thanks everyone for the help and suggestions. I will keep you posted on the results. But that will have to wait for a bit, since I am going away for a while (no I didn't get caught and I'm not going to the Big House, it's a short vacation)