I built an 11 ft table by putting a door next to my 4x4 ft saw table. It was leveled with a laser so the two surfaces were co-planar. the laser level came from a liquidator and cost $6US. Then I made eight cradles out of plywood with cork lining to fit the glass tube. The glass came in 5 ft lengths and I had it cut and annealed to 4,3,2 and 1 ft. The four ft length is being held in reserve, the 3,2 and 1 with the other fittings will give a total column height as great as 9 ft.

The cradles had identical alignment targets that I made on my laser printer from CAD drawings. I lined them up one by one and fixed them to the table with adhesive tape. When I placed the glass tubing in the cradles, the laser beam (with a crosshair pattern) went right through the middle of the tubes. The symetrical pattern of the laser reflections shows the alignment is correct. Moving one of the tubes a tiny amount would wreck the symmetry.

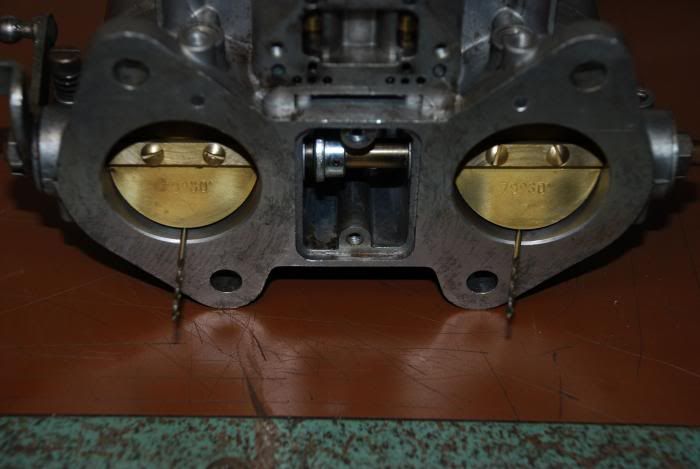

With the tubes all aligned, I inserted the joints and luted them with flour paste. The joints were aligned with each other by connecting them with a coupling and rotating the tubes in opposite directions. After the the lute hardened, I sealed the outside end with silicone. This closeup shows the joint: lute, three layers of soft cotton crochet yarn and silicone. In the background is a cradle with alignment target.

The male joints are a copper coupling with a piece of pipe. The female joints are just a coupling. I polished the mating surfaces with 400 grit sandpaper, 000 steel wool and then a buffer with polishing compound. They slide in and out very smoothly. The final seal will be a strip of cork and a stainless steel band clamp. The joint is very strong.

Soon I will be using the tubes to measure flow rates and back pressure of gas and water in a packed column. I'll post that when I have some results.