Newbie not getting the proof I was expecting??

Moderator: Site Moderator

-

Beerswimmer

- Trainee

- Posts: 931

- Joined: Tue Sep 29, 2009 1:33 pm

- Location: In the garage

Re: Newbie not getting the proof I was expecting??

I just went to the hardware store and bought insulation, and y-valves. Hopefully that'll solve 99% of my problem. Human error is still going to be the biggest obstacle!!! Also Milehi contacted me and we talked over the phone about ways to make this work like it should. That's some amazing customer service!!!

Now I just a wash to do a reflux run with!!!!

Now I just a wash to do a reflux run with!!!!

Ut Alii Vivant!!!!

-

Hillbilly Bill

- Novice

- Posts: 17

- Joined: Sun Nov 01, 2009 6:08 am

- Location: On the River 'tween the Hills

Re: Newbie not getting the proof I was expecting??

Hi guys,

Let me know if I am out of line here... I have always used a reflux column (original mini-bok) and even on this small tower I have to keep my collection valve closed until I have reached a nice equilibrium in the low 170's. Then I open the valve slowly until I get a slow drip into the collection jar. I am not able to keep a steady stream going, but my first runs have always been at around 95% abv. I have never needed to make a second run. (I toss the first 50ml and also toss all tails that I can smell... usually those are collected when my thermometer reaches 182 degrees F. No sense, in my opinion, to run them again... just asking for a headache. Maybe a little patience would give us the results we are looking for here.

Thanks for letting me stick my nose in...

Bill

Let me know if I am out of line here... I have always used a reflux column (original mini-bok) and even on this small tower I have to keep my collection valve closed until I have reached a nice equilibrium in the low 170's. Then I open the valve slowly until I get a slow drip into the collection jar. I am not able to keep a steady stream going, but my first runs have always been at around 95% abv. I have never needed to make a second run. (I toss the first 50ml and also toss all tails that I can smell... usually those are collected when my thermometer reaches 182 degrees F. No sense, in my opinion, to run them again... just asking for a headache. Maybe a little patience would give us the results we are looking for here.

Thanks for letting me stick my nose in...

Bill

It ain't all that bad, is it?

Re: Newbie not getting the proof I was expecting??

Hi Hillbilly Bill, no, you are not out of line. You just have a different kind of still. We were just trying to work the kinks of of it. Always feel free to chime in at any time.

I know I learned a thing or three from kiwistiller. He wrote a post about operating a still much like Beerswimmer's in concept and posted a link to it in this thread. I doubt I will ever need to use the wisedom of it since I don't have a still like his but it was beautifully written with loads of good information.

If you cannot keep a steady stream, I'd suspect that your boiler power is not steady enough or your rig is getting a bit of wind on it. You have insulation on it? You running your boiler with a hot plate or something that cycles on and off?

Oh by the way Beerswimmer, what suggestions did Milehi have?

Fester

I know I learned a thing or three from kiwistiller. He wrote a post about operating a still much like Beerswimmer's in concept and posted a link to it in this thread. I doubt I will ever need to use the wisedom of it since I don't have a still like his but it was beautifully written with loads of good information.

If you cannot keep a steady stream, I'd suspect that your boiler power is not steady enough or your rig is getting a bit of wind on it. You have insulation on it? You running your boiler with a hot plate or something that cycles on and off?

Oh by the way Beerswimmer, what suggestions did Milehi have?

Fester

-

Beerswimmer

- Trainee

- Posts: 931

- Joined: Tue Sep 29, 2009 1:33 pm

- Location: In the garage

Re: Newbie not getting the proof I was expecting??

I just bought the insulation today, I guess nI'll throw it on tonight and maybe take a pic. I also bought y-valves. I have a hotplate that does cycle, and I might switch to one that doesn't, but the temps seem to be stable

Milehi said to run the lines like you suggested, and to fill the entire column with packing. He's also sending me some rasching rings to use. Insulate, and that the water is cold Seemed like a great guy who is trying to help!!

Seemed like a great guy who is trying to help!!

I re-read Kiwi's post again this morning. The mind plan I have after reading his post is to hook up the lines to the bottom of each condenser and run them full-on while the boiler is heating up to 170F. Then slowly,slowly,slowly turn the water pressure down on the top condenser until I get some product to come out. Then maybe I'll have to turn the water pressure down a touch more to get the heads to come out and then a little more for the hearts. Keep it set like that. Sound about right?

The temp in the kitchen fluctuates drastically between 68F and 40F everytime I open the door to fiddle with the hose! Now that I have the y-valves I won't have to anymore, that's gotta help!

Milehi said to run the lines like you suggested, and to fill the entire column with packing. He's also sending me some rasching rings to use. Insulate, and that the water is cold

I re-read Kiwi's post again this morning. The mind plan I have after reading his post is to hook up the lines to the bottom of each condenser and run them full-on while the boiler is heating up to 170F. Then slowly,slowly,slowly turn the water pressure down on the top condenser until I get some product to come out. Then maybe I'll have to turn the water pressure down a touch more to get the heads to come out and then a little more for the hearts. Keep it set like that. Sound about right?

The temp in the kitchen fluctuates drastically between 68F and 40F everytime I open the door to fiddle with the hose! Now that I have the y-valves I won't have to anymore, that's gotta help!

Ut Alii Vivant!!!!

-

kiwistiller

- retired

- Posts: 3215

- Joined: Tue Mar 03, 2009 4:09 pm

- Location: Auckland, NZ

Re: Newbie not getting the proof I was expecting??

sounds right except for the last bit, keep it set like that. after you're collecting heads, the way to find a good flow rate is to watch your head temp, and ease off the water to the reflux condenser, little by little. all of a sudden, the head temp will want to jump up, increase cooling again til it drops, and you're in a good spot. take a note of this flow rate (measure it if you can rather than relying on an idea of valve setting). the annoying thing about CM stills is this flow rate that is the sweet spot of production rate vs proof at the START of hearts will not be the same throughout. as the amount of ethanol in the boiler decreases, the amount of cooling water required will increase, and the head temp will 'want' to spike. you need to increase cooling at this point, or you will have a lower proof, and probably do some harm to the flavour of your neutral. So you need to be on the ball with water flow and temp, throughout the run. Trust me, if you walk away for 5 mins, the bastard will choose that moment to jump. When I ran my cm I'd preemptively raise coolant flow if I needed to go take a leak or whatever.Beerswimmer wrote: I re-read Kiwi's post again this morning. The mind plan I have after reading his post is to hook up the lines to the bottom of each condenser and run them full-on while the boiler is heating up to 170F. Then slowly,slowly,slowly turn the water pressure down on the top condenser until I get some product to come out. Then maybe I'll have to turn the water pressure down a touch more to get the heads to come out and then a little more for the hearts. Keep it set like that. Sound about right?

at risk of a Wikipedian protester calling me out, I'm pretty sure that copper mesh outperforms rings.Beerswimmer wrote:He's also sending me some rasching rings to use.

Don't fill above the reflux condenser.Beerswimmer wrote:and to fill the entire column with packing.

kiwi

Three sheets to the wind!

My stuff

My stuff

-

Beerswimmer

- Trainee

- Posts: 931

- Joined: Tue Sep 29, 2009 1:33 pm

- Location: In the garage

Re: Newbie not getting the proof I was expecting??

So I started to go from a really pretty stainless piece of art:

To an ugly but insulated column with the new y-valve:

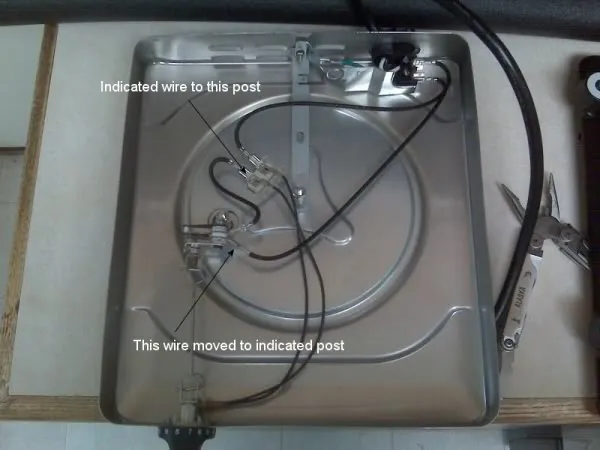

And here are the hotplate guts, anyone know how to make it stop cycling??

To an ugly but insulated column with the new y-valve:

And here are the hotplate guts, anyone know how to make it stop cycling??

Ut Alii Vivant!!!!

Re: Newbie not getting the proof I was expecting??

Hands down winner. By a factor of at least 2.I'm pretty sure that copper mesh outperforms rings.

IIRC, one advantage Raschig rings do have is that they do not have the problem of reflux channelling that can occur with mesh/scrubbers in the lower regions of the column. Rings keep it much more evenly spread across the column all the way down.

Be safe.

Be discreet.

And have fun.

Be discreet.

And have fun.

Re: Newbie not getting the proof I was expecting??

follow the rod from the nob, that on the other end is the thermostat, attach those two wires together (caution it will be on high all the time)

Re: Newbie not getting the proof I was expecting??

It is the very things that we think we know, that keep us from learning what we should know.

Valved Reflux, 3"x54" Bok 'mini', 2 liebig based pots and the 'Blockhead' 60K btu propane heat

Valved Reflux, 3"x54" Bok 'mini', 2 liebig based pots and the 'Blockhead' 60K btu propane heat

Re: Newbie not getting the proof I was expecting??

that will do it.

-

Beerswimmer

- Trainee

- Posts: 931

- Joined: Tue Sep 29, 2009 1:33 pm

- Location: In the garage

Re: Newbie not getting the proof I was expecting??

Oh, I was hoping to still be able to control the temp  I'm pretty sure I don't want it on high all the time, especially since I'll be running this in pot mode most of the time.

I'm pretty sure I don't want it on high all the time, especially since I'll be running this in pot mode most of the time.

Ut Alii Vivant!!!!

Re: Newbie not getting the proof I was expecting??

instead try putting a heavy steel plate between the hotplate and the still,, old cast iron frying pan, brake rotor something like that.

-

Beerswimmer

- Trainee

- Posts: 931

- Joined: Tue Sep 29, 2009 1:33 pm

- Location: In the garage

Re: Newbie not getting the proof I was expecting??

I have tons of 1/4" steel plates!! They are what I shoot my .50BMG at!!!!

Ut Alii Vivant!!!!

Re: Newbie not getting the proof I was expecting??

Spare one of those steel plates for use as a heat diffuser, at least until you can get a controller to use in place of the temperature control on that hot plate... If the plate is of adequate size it'll smooth out the cycling that is taking place... I use one on my electric kitchen stove and it really helps at some power settings...

Re: Newbie not getting the proof I was expecting??

I just found this thread and have similar issue. I have a Milehi 40" x 3" tower that I recently purchased. It is of the newer design that has a torpedo type condenser in the top instead of the jacket as has been discussed in this thread. I have it on top of one of his 13 gallon milk cans and with that much boil, I am using a propane burner. I have the tower insulated - hated to cover up that beautiful stainless - and so far have run copper scrubbers as packing but I recently purchased some raschid rings to fill half of the column with and use copper for the remainder. The best overall ABV I have been able to achieve is about 83%. I have a very difficult time getting the temperature to stabilize and remain steady - it can sometimes fluctuate up to 10 or more degrees.

My questions are these: with this different type of condenser on my still, should I make the same changes as discussed above to the water flow with the valves and splitters? I have well water that runs a little warmer than discussed in the above thread.

I'm sure it is mostly experience on my part, but I am having difficulty finding the right point to make the cuts between heads, hearts and tails. That might be because of the unstable temp causing there to not be a very defined point. My last batch also tasted very sweet - but I think that is because the fermentation didn't go that well and never quite finished so the water that is left in the product may have contributed the sweetness.

Thanks for all of your help -

Greg

My questions are these: with this different type of condenser on my still, should I make the same changes as discussed above to the water flow with the valves and splitters? I have well water that runs a little warmer than discussed in the above thread.

I'm sure it is mostly experience on my part, but I am having difficulty finding the right point to make the cuts between heads, hearts and tails. That might be because of the unstable temp causing there to not be a very defined point. My last batch also tasted very sweet - but I think that is because the fermentation didn't go that well and never quite finished so the water that is left in the product may have contributed the sweetness.

Thanks for all of your help -

Greg