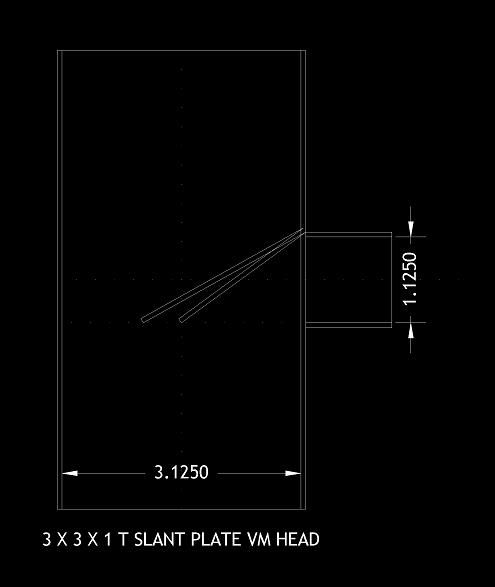

minime wrote:I'm not sure at which point the smaller diameter would make a difference but the collapsing vapors have to be creating some kind of void and the pressure of the rising vapor in the column is pushing also. I think once the vapor stream has been split the collapsing has already begun.

Here's my twist on things... One issue that needs to be factored into the equation is the fact that once the vapor has been split off from rising, heads horizontal, and then drops through an elbow, much of the battle has been won... Having a smaller diameter condenser is actually a benefit in this configuration...

As for the reflux condenser, we need to look at that from a different perspective... With the reflux condenser located above the take-off point the vapor will require more volume to slow the upward movement... A larger volume of vapor area and condenser area is required to knock the vapor back down...

Now, would we ever get to a point where the reflux condenser is so efficient that it will rob the take-off point of any vapors...??? Very doubtful... And given the fact that minime has gone so far as to terminate the slant plate below the take-off point, he has further insured against such an occurrence...

All in all, I think this design will be very efficient and I hope minime's results are proof positive... C'mon, minime, the suspense is killing me...